Specific Process Knowledge/Thin film deposition/Deposition of Chromium/Deposition of Chromium

Uniformity of Cr layers

Cr have been deposited with both E-beam evaporation and sputtering deposition to see if there are differences in the uniformity of the Cr layers.

Experimental

Cr depositions have been done directly on unprocessed Si wafers, all depositions has been done in Wordentec. The deposited layers have therafter been examined with AFM.

Results

There are differences in uniformity and grain size, for the various deposition methods. For the sputtering processes there are large differences depending on the settings during the process, i. e. Ar pressure and effect.

E-beam process

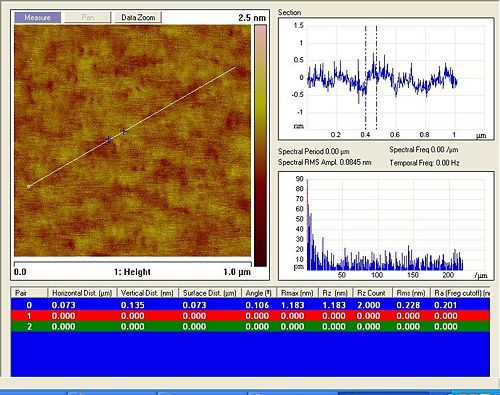

The Cr layer deposited with e-beam in the Wordentec has a low roughness, and are uniform. The deposition rate has been 10 Å/s.

Sputting prosess

In the Wordentec the Ar pressure can be set to between and mbar during the process, and the effect may be varied between 150 and 400 W.

Here are AFM pictures sputtered layers, deposited with dirrerent settings, shown.

Effect 150 W, pressure mbar

With these settings the deposited layers are uniform and has a low roughness.

(Please contact Katharina Nilson if you have any questions.)