Specific Process Knowledge/Thin film deposition/ALD2 (PEALD)/TiN deposition using ALD2

Feedback to this page: click here

General information

As already mentioned in the general ALD2 (PEALD) page oxides and nitrides cannot be deposited at the same time. Since the aluminium nitride requires the plasma source we only run all nitride processes without the thermal lid. Hence the chamber volume is bigger than with the thermal lid which causes that the substrate temperature is around 50 °C lower than the setpoint.

Result from acceptance test

TiN with NH3

The test was done with 2000 cycles at 450 °C where the average growth rate was measured to be 0.0173 nm/cycle.

| TiCl4 | NH3 | |

|---|---|---|

| Nitrogen flow | 100 sccm | 100 sccm |

| Pulse time | 0.1 s | 2.0 s |

| Purge time | 2.0 s | 6.0 s |

Unlikely the other ALD2 materials TiN cannot be measured using the ellipsometer. Hence one has to cleave the wafer and measure the thickness in the SEM. Thin layers (less than 12 nm) are difficult to focus on due to charging and vibrations and may not be measured properly.

-

TiN crossection of a sample with 2000 cycles deposition at 400 °C on a silicon wafer with thermal oxide. The TiN thicknes is 35.8 nm and the SiO2 thickness is 173.8

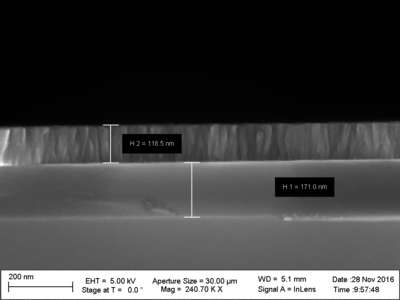

TiN crossection of a sample with 5000 cycles deposition at 400 °C on a silicon wafer with thermal oxide. The TiN thicknes is 118.5 nm and the SiO2 thickness is 171.0

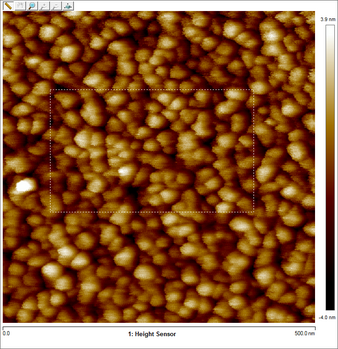

The AFM measured roughness was 0,7415 nm.

Pernille Voss Larsen, Mikkel Dysseholm Mar and Tanja Amport, DTU Danchip, 2016-2017.

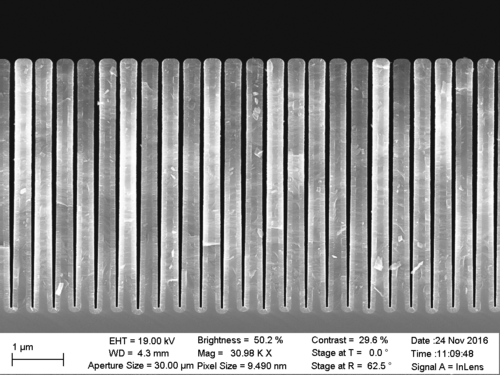

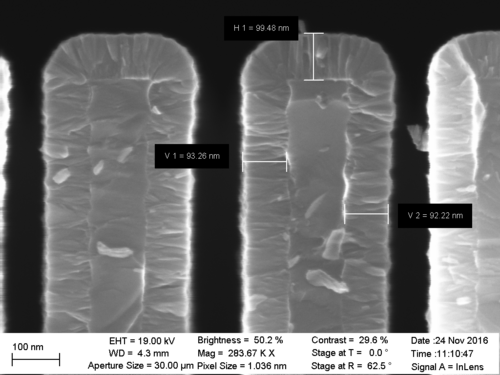

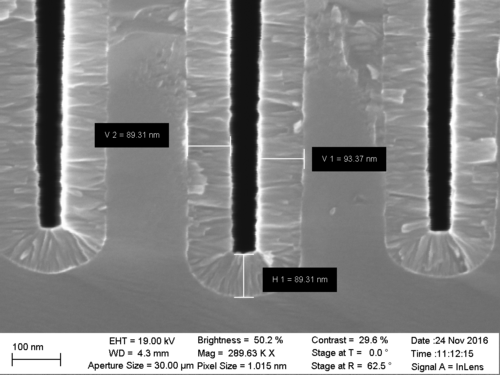

TiN with NH3 on trenches

The test was done with 4000 cycles at 450 °C where the average growth rate was measured to be 0.0232 nm/cycle.

| TiCl4 | NH3 | |

|---|---|---|

| Nitrogen flow | 100 sccm | 100 sccm |

| Pulse time | 0.5 s | 5.0 s |

| Purge time | 2.0 s | 6.0 s |

The SEM images below show a homogeneous coverage all over the trenches.