Specific Process Knowledge/Thin film deposition/ALD2 (PEALD)/HfO2 deposition using ALD2

Appearance

Result from acceptance test

HfO2 deposition using TEMAHf and H2O precursors

The test was done with 400 cycles at 250 °C where the growth rate was measured to be 0.0804 nm/cycle.

| TEMAHf | H2O | |

|---|---|---|

| Nitrogen flow | 200 sccm | 150 sccm |

| Pulse time | 1.5 s | 0.1 s |

| Purge time | 6.0 s | 6.0 s |

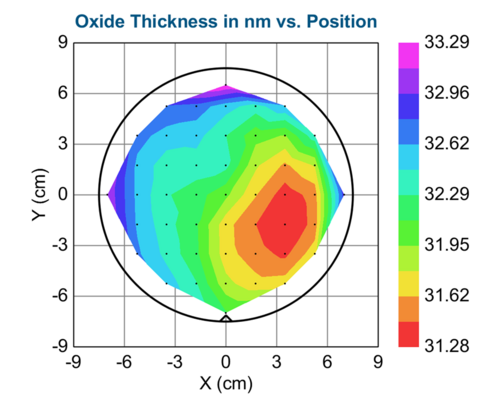

Uniformity profile across 150 mm Si wafer based on 49 measurement points measured with ellipsometer. The values for the grown oxide thickness can be seen in the table below.

| Parameter | Average | Min. | Max. | Std.Dev | %Range |

|---|---|---|---|---|---|

| Thickness (nm) | 32.16 | 31.28 | 33.29 | 0.49 | 6.2486 |

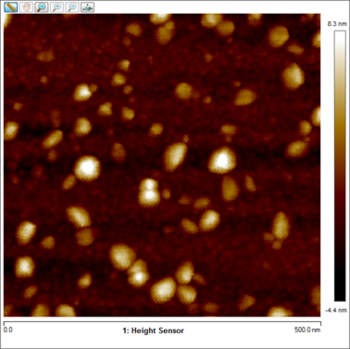

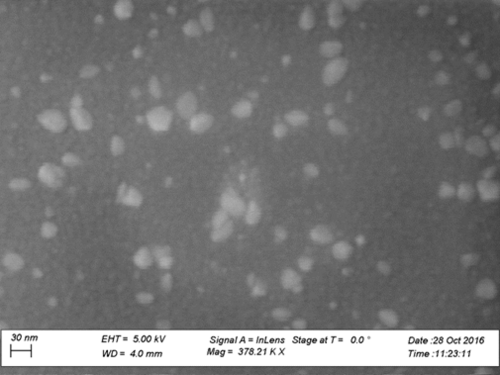

The AFM measured roughness was 2.09nm. The high roughness value occurred due to formation of clustered Hf2 which are also visible in the SEM as shown in the figure below.

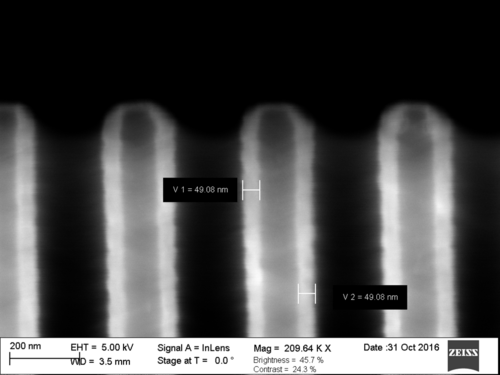

HfO2 deposition on trenches using TEMAHf and H2O precursors

The test was done with 400 cycles at 250 °C where the growth rate was measured to be between 0.954-0.122 nm/cycle depending on the depth.

| TEMAHf | H2O | |

|---|---|---|

| Nitrogen flow | 200 sccm | 200 sccm |

| Pulse time | 1.5 s | 10 s |

| Purge time | 20.0 s | 20.0 s |

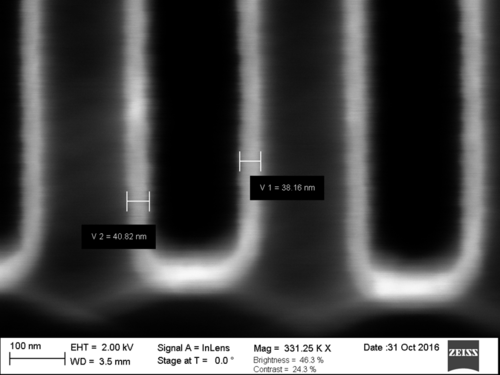

The SEM images below show that a higher coverage occurred at the top compared to the bottom. The difference is roughly around 10 nm.