Specific Process Knowledge/Lithography/ARP617

These tests are currently in progress and this page thus under construction. If you have questions to the process or wish to use this e-beam resist, please contact Tine Greibe at tigre@danchip.dtu.dk.

Process Flow

Test of copolymer AR-P 617.05; a positive e-beam resist from AllResist. This copolymer is meant to be used as a sacrificial layer in a bi- or tri-layer e-beam resist stack (i.e. bottom layer). The copolymer adheres well on many substrates and can be dry-etched isotropically (to create under-cut) and anisotropically by reactive ion etch.

| Equipment | Process Parameters | Comments | Initials and date |

|---|---|---|---|

| Pretreatment | |||

| 4" Si wafers | No Pretreatment | TIGRE, 13-06-2014 | |

| Spin Coat | |||

| Spin Coater Manual, LabSpin, A-5 | AR-P 617.05 AllResist E-beam resist

60 sec at various spin speed. Acceleration 2000 s-2, softbake 10 min at 200 deg Celcius |

Resist poured by use of disposable pipette | TIGRE, 13-06-2014 |

| Characterization | |||

| Ellipsometer VASE B-1 | 9 points measured on 100 mm wafer | ZEP program used; measured at 70 deg only | TIGRE, 13-06-2014 |

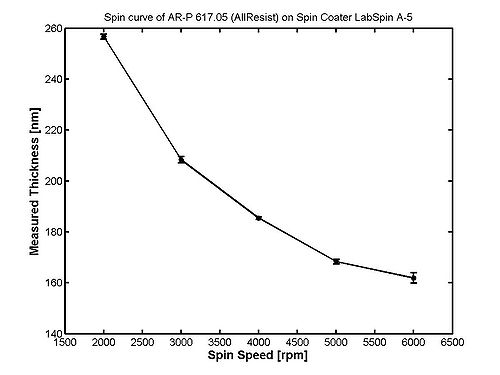

Spin Curve

The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only.

9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers.

| AllResist AR-P 617.05 spinning on Spin Coater: Manual LabSpin A-5, TIGRE, 13-06-2014 | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 2000 | 2000 | 256.70 | 0.96 | |||

| 3000 | 2000 | 208.33 | 1.24 | |||

| 4000 | 2000 | 185.41 | 0.50 | |||

| 5000 | 2000 | 168.34 | 0.88 | |||

| 6000 | 2000 | 161.90 | 1.99 | |||