Specific Process Knowledge/Thin film deposition/ALD Picosun R200/Al2O3 deposition using ALD

Feedback to this page: click here

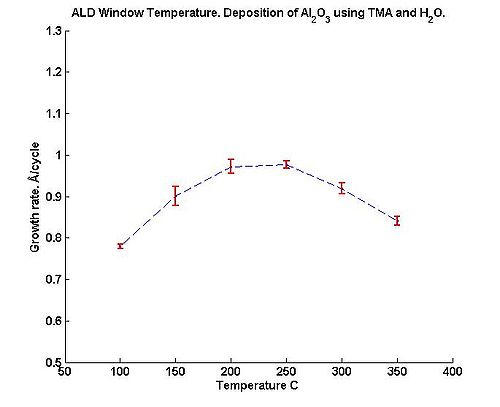

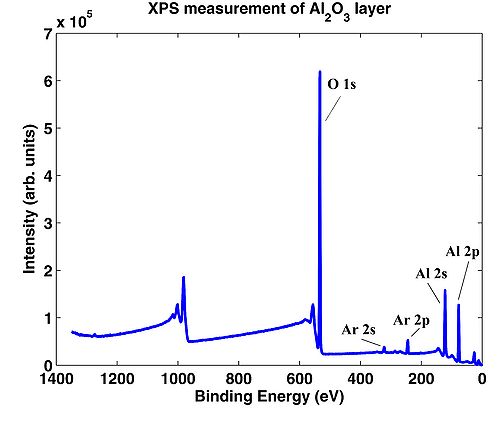

The ALD window for depostion of aluminium dioxide (Al2O3) ranges from 150 oC to 350 oC. XPS measurements shows that at temperatures below 150 oC the Al2O3 layer will be contaminated by unreacted TMA molecules, and at temperatures above 350 oC the TMA decomposes.

All results shown on this page have been obtained using the "AL2O3" recipe on new Si(100) wafers with native oxide:

Al2O3 standard recipe

Recipe: AL2O3

Maximum thickness: 100 nm

Temperature: 100 oC - 350 oC

| TMA | H2O | |

|---|---|---|

| Nitrogen flow | 150 sccm | 200 sccm |

| Pulse time | 0.1 s | 0.1 s |

| Purge time | 3.0 s | 4.0 s |

Al2O3 deposition rates

The deposition rate for Al2O3 depends on the temperature, see the ALD-window graph below. The uniformity, thickness, refractive index has been obtained using Ellipsometer VASE.

-

ALD-window for Al2O3 deposition.

-

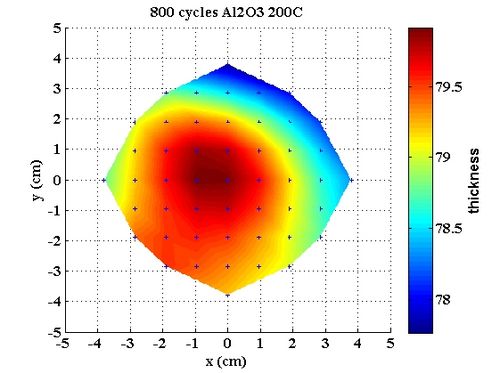

Typical uniformity profile across 100mm Si wafer based on 49 mesurement points.

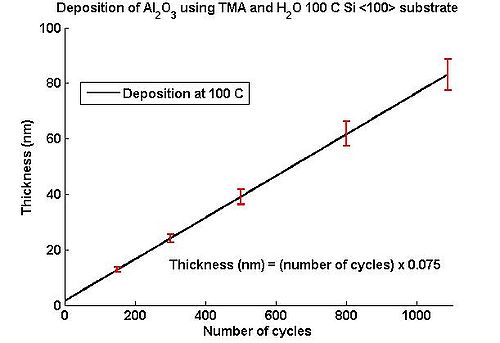

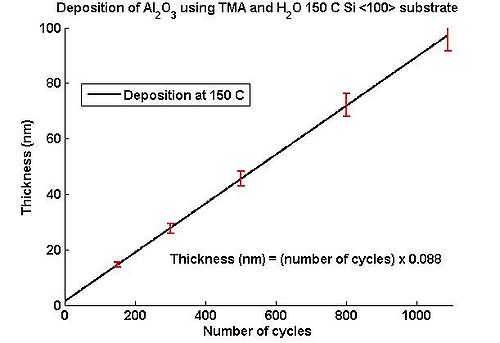

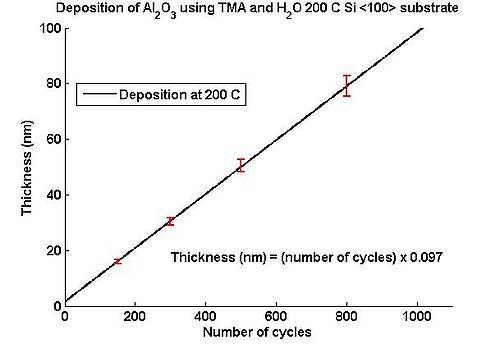

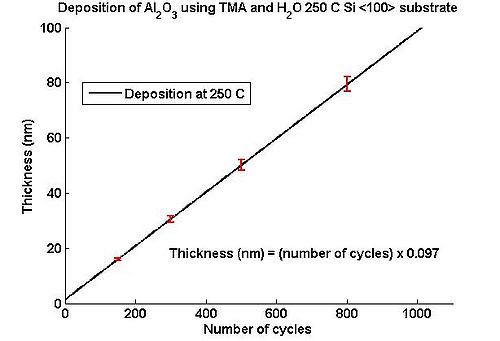

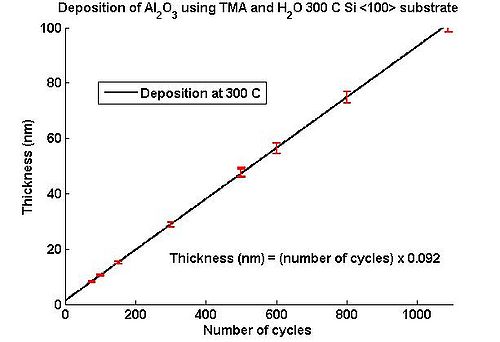

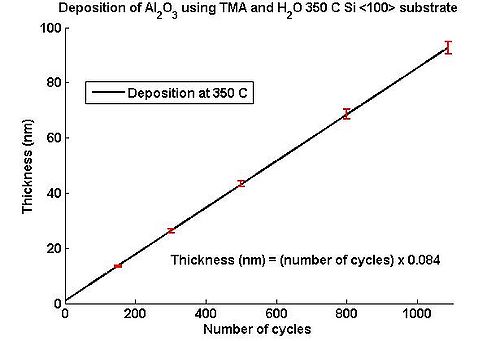

In the graphs below the Al2O3 thickness as function of number of cycles for deposition temperatures between 100 oC and 350 oC can be seen. From the equations the number of cycles required for a certain thickess can be calculated.

- Aluminium oxide thickness as function of number of cycles

-

Temperature 100 oC.

-

Temperature 150 oC.

-

Temperature 200 oC.

- Aluminium oxide thickness as function of number of cycles

-

Temperature 250 oC.

-

Temperature 300 oC.

-

Temperature 350 oC.

Evgeniy Shkondin, DTU Danchip, 2014-2016.

Al2O3 standard recipe characterization across 100 mm Si <100> wafer

| Al2O3 deposition at 100 oC and 150 oC | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

| Al2O3 deposition at 200 oC and 250 oC | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

| Al2O3 deposition at 300 oC and 350 oC | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Evgeniy Shkondin, DTU Danchip, 2014-2016.

Al2O3 XPS investigation for elemental trace analysis

Typical XPS profile for Al2O3

|

|---|

Evgeniy Shkondin, DTU Danchip, 2014-2016.

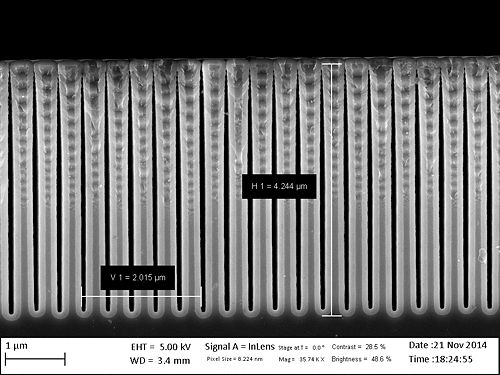

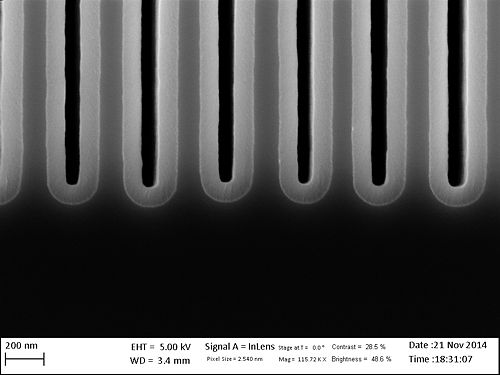

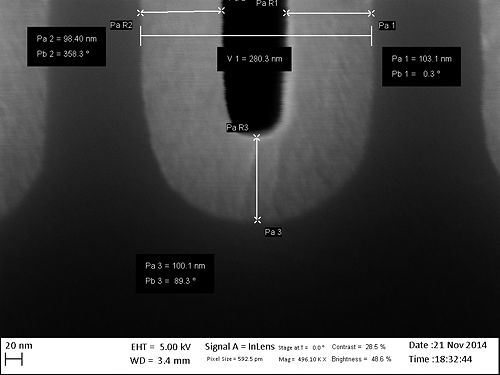

Al2O3 recipe for deposition on high aspect ratio structures

Recipe: AL2O3T

Maximum thickness: 100 nm

Temperature: 100 oC - 350 oC

| TMA | TMA | H2O | H2O | |

|---|---|---|---|---|

| Nitrogen flow | 150 sccm | 150 sccm | 200 sccm | 200 sccm |

| Pulse time | 0.1 s | 0.1 s | 0.1 s | 0.1 s |

| Purge time | 0.5 s | 20.0 s | 0.5 s | 20.0 s |

The recipe is good for deposition on very high aspect ratio structures (with aspect ratio more then 1:20) such as deep trenches, pillars, pores etc. However, in most cases, including deposition on black silicon or other lower aspect ratio structures, the standard Al2O3 recipe is sufficient and should be used instead! A2O3T can also be used for deposition on polymers at low temperatures (80-120 oC). Deposition rate is approximately the same as for standard Al2O3 recipe.

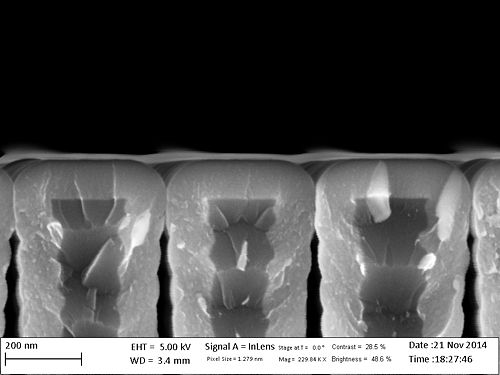

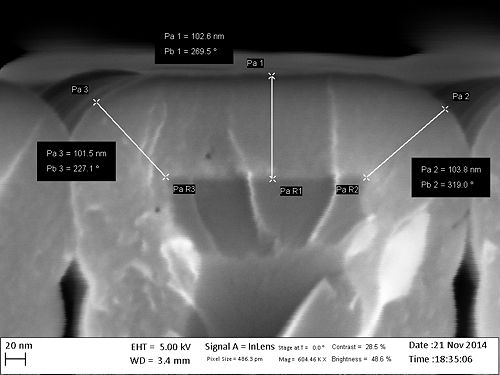

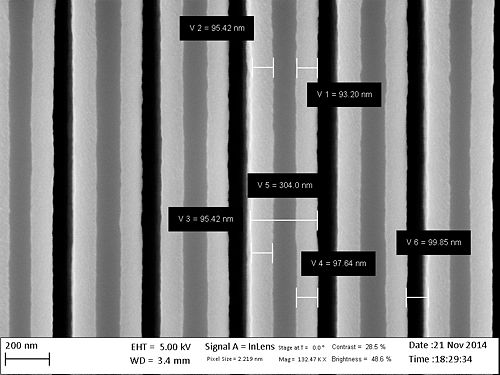

Some some SEM images of Al2O3 deposited on a Si trenches at 150 oC temperature and 1000 cycles. Trenches prepered using DRIE-Pegasus. Research results based on this recipe can be found here: LINK

- Al2O3 coatings on Si trenches

-

Temperature 150 oC, 1000 cycles.

-

Temperature 150 oC, 1000 cycles.

-

Temperature 150 oC, 1000 cycles.

-

Temperature 150 oC, 1000 cycles.

-

Temperature 150 oC, 1000 cycles.

-

Temperature 150 oC, 1000 cycles.

Evgeniy Shkondin, DTU Danchip, 2014-2016.

Al2O3 ozone recipe

Recipe: AL2O3 O3

Maximum thickness: 100 nm

Temperature: 300 oC - 350 oC

| TMA | O3O | |

|---|---|---|

| Nitrogen flow | 150 sccm | 200 sccm |

| Pulse time | 0.1 s | 0.2 s |

| Purge time | 3.0 s | 4.0 s |

Oxidizing agent in this process is ozone instead of water. The advantage of using ozone is minimization of hydrogen impurities in the deposited film.

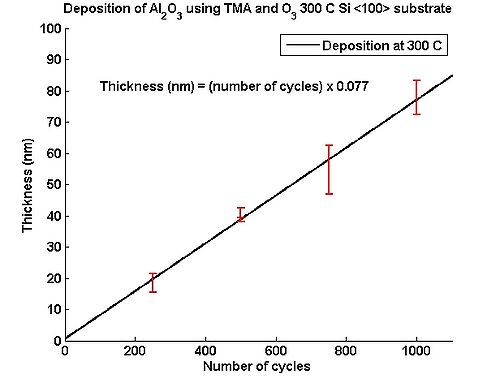

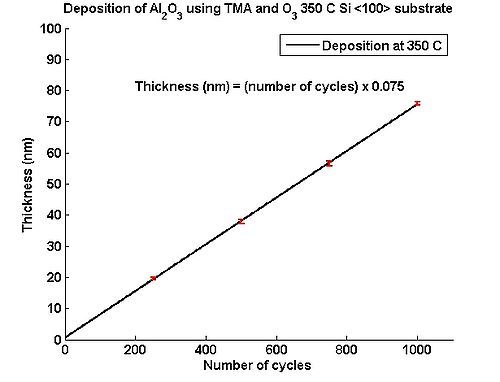

Al2O3 O3 process deposition rates

The deposition of Al2O3 using O3 can be done in the range between 300-350 oC. It is not recomanded to put temperature below 300oC since it leads to very poor uniformity, which is somewhat lower compared with water process even at 300oC (data obtained using Ellipsometer VASE). This recipe is not sutable for deposition on high aspect ratio structures (use recipe Al2O3 or Al2O3T instead).

-

Thickness distriburion across 100mm Si wafer (300oC).

-

Thickness distriburion across 100mm Si wafer (350oC)

In the graphs below the Al2O3 thickness as function of number of cycles for deposition temperatures between 300 oC and 350 oC can be seen. From the equations the number of cycles required for a certain thickess can be calculated.

- Aluminium oxide thickness as function of number of cycles

-

Temperature 300 oC.

-

Temperature 350 oC.

Evgeniy Shkondin, DTU Danchip, 2014-2016.

Al2O3 O3 recipe characterization across 100 mm Si <100> wafer

| Al2O3 deposition at 100 oC and 150 oC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Evgeniy Shkondin, DTU Danchip, 2014-2016.