Specific Process Knowledge/Characterization/XPS/XPS technique

Appearance

Feedback to this page: click here

XPS technique

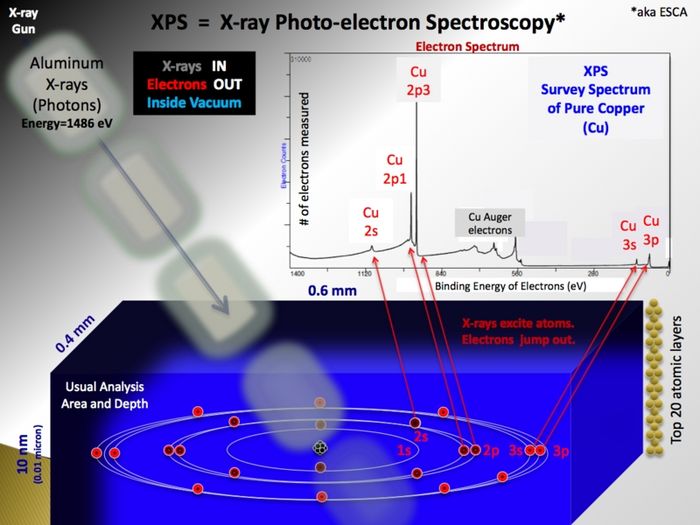

XPS is a surface sensitive and non destructive technique used for analysis of the elemental composition of a sample. The basic principle is shown below.

The analysis relies on the sequence:

- The X-ray source

- In the X-ray gun, electrons are extracted from a filament and accelerated by a high voltage onto an aluminium anode. Here, much like the primary beam in an SEM, X-rays with the characteristic energy of aluminium (1486.7 eV) are generated. Emitted isotropically, some X-rays hit a quartz crystal that act as monochromator as the X-rays diffract on the crystal planes according to the Bragg equation. If curved, the crystal will also focus the beam of X-rays and in this way enable us to use X-ray spots (in the shape of ellipses) of different sizes - ranging from 400 µm to 40 µm. The smaller spots, however, only come at the price of a drastically lowered intensity - therefore it is generally advised only to use the default value of 400 µm unless strictly necessary for some reason.

- Generation of photoelectrons

- As the incoming and monochromatic X-rays (with energy Ephot) impinge on and travel through the sample, they may react with electrons bound to atoms in the sample with a certain binding energy (Ebind). The result is free electron inside sample with a kinetic energy (Ekin=Ephot-Ebind) that is characteristic of the atomic level it originated from. As the binding energy depends on the small energy changes in the electronic states induced by the formation of chemical bonds, the electron also carries information about the chemical state.

- Transport towards the vacuum

- The inelastic mean free path of the photoelectrons is very short.

- Detection in the analyzer

This causes all electrons undergo inelastic collisions with sample electrons and a tail of

X-ray Photoelectron Spectroscopy analysis (XPS)

Typical applications of XPS

The XPS can be used for different applications, for example:

- Do an elemental analysis of the outermost layer of your surface.

- Check the composition of a film at different depths.

- Check for a contaminations.

- It not as sensitive as the SIMS, but faster, so it can be an alternative if you are checking for a bit higher contamination levels (like 1 %)

- Do a analysis of the chemical state of atoms present on the surface.

- See what effect a surface treatment of your sample has on the surface chemistry.

- Check a polymer covered surface. Are for example (C=O), (C-OH) (C-C) groups present in the polymer after it been deposited on a surface.