Specific Process Knowledge/Thermal Process/BCB Curing Oven

Appearance

This page is under contruction

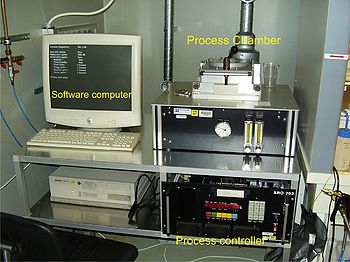

BCB Curing Oven

The BCB Curing Oven is mainly used for curing of BCB (bisbenzocyclobutene) and for alloying of metal in a nitrogen atmosphere.

During processing the furnace is rapidly heated by use of five halogen lamps below the sample. The furnace is purged with a controlable nitrogen flow. There is vacuum on the furnace.

The user manual, user APV, technical information and contact information can be found in LabManager:

Process information

There are no standard processes on the furnace.

| Equipment | Resist Pyrolysis Furnace | |

|---|---|---|

| Purpose |

| |

| Process parameter range | Temperature |

|

| Nitrogen flows |

| |

| Substrates | Batch size |

|

| Allowed materials |

| |