Specific Process Knowledge/Wafer cleaning/Cleaning with Soap Sonic

Feedback to this page: click here

Cleaning of samples that have been out of the cleanroom

The soap sonic is done in a tank with ultrasonics placed in the cleaning bench in the changing room. The cleaning solution is DI water to which a little diluted Triton X-100 is added. Triton X-100 is a nonionic detergent which is metal ion free. This detergent is added to reduce surface tension and thus help removing particles from the samples to be cleaned.

It is used for samples (typical wafers or chips) that have been out of the cleanroom e.g. if they have been diced, and you want to bring them in again for measurement or further processing. In most cases the Triton X-100 sonic clean is not enough. The samples will also have to be cleaned in a piranha solution. You must always ask DTU Nanolab for permission to bring your samples back into the cleanroom once they have been out of the cleanroom.

Procedure

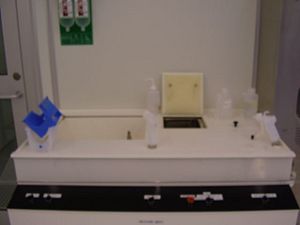

The bench in gowning contains a sink, an ultrasonics bath and a rinse bath for rinsing samples cleaned in Triton X-100. To clean the samples:

- Find a suitable holder for your samples in the cupboard below the baths

- Make sure the ultrasonics bath dump valve is closed

- Fill the ultrasonics bath (the one made of metal) with DI water (enough to completely cover your samples)

- Add 20 - 30 drops of diluted Triton X-100 detergent (From the rinse/spray bottle. Do NOT use undiluted Triton X-100)

- Close the bath lid to minimize noise from the ultrasonics bath

- Start ultrasonics on the front panel

- Leave sample in ultrasonics for 10 min

- Switch off ultrasonics

- Fill rinse bath (the one made in plastic) with DI water and rinse your samples

- Remove samples and dry them

- Dump the Triton X-100 solution and rinse baths to drain. Rinse tanks with DI water. Leave dump valves open so the baths drain completely

- Continue with piranha.