LabAdviser/Technology Research/Organic Ice Resists for Electron-Beam Lithography - Instrumentation and Processes/SEM-LEO Customizations for Organic Ice Resists

Feedback to this page: click here

SEM-LEO Customizations for Organic Ice Resists

Overview

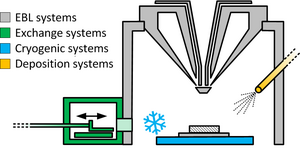

The standard EBL setup, consisting in a vacuum chamber, a moving stage for sample navigation and an electron-beam gun for imaging and exposure, is not sufficient by itself to provide the necessary conditions to investigate lithography on ice layers: no chamber inlet is available for injecting gas precursors, and sample holders are evidently at room-temperature.

The LEO SEM has been provided with a dedicated load-lock and transfer system. Through removable add-ons, it can cool down and warm up, and image or expose samples under cryogenic conditions. Gas can be prepared in the external apparatus and injected into the chamber, and it is possible to monitor the whole process in terms of temperature, pressure, atmosphere composition, and so on. The SEM is now a functional, self-contained lithography system for ice processing.