Specific Process Knowledge/Etch/DRIE-Pegasus/System-description

The Bosch process at the DRIE-Pegasus

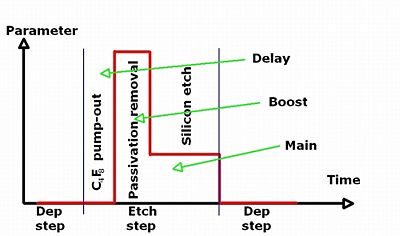

The DRIE-Pegasus takes the well established Bosch process known from the ASE a significant step further. In the ASE the Bosch process has two cycles, etch and passivation. During each cycle the process parameters are kept constant:

- In the passivation cycle, a C4F8 plasma is formed using the RF coil power only and a teflon-like coating is created on all surfaces thus protecting the sidewalls in the subsequent etch cycle.

- In the etch cycle

- the ion bombardment driven by the platen power first removes the passivation layer on the surfaces directly exposed to the ions (i.e. horizontal surfaces)

- then as the bottom of the structures are opened the etch of silicon itself starts.

Here, it is clear that one can distinguish two phases of the etch cycle; one where the ion bombardment removes the polymer and one where the actual etching of silicon takes place. Considering what process conditions are favorable we realize that

- the ion bombardment requires a low pressure in order for the ions to have a long mean free path and hence good directionality. Also, a high platen power is required to drive the ion bombardment.

- a higher pressure during the etch increases the density of reactive species and hence the etch rate. Since a high platen power is no longer necessary to drive the ion bombardement, lowering it will reduce the impact on the masking material thus improving the selectivity.

These conflicting demands are the same on the ASE. However, with hardware improvements on the DRIE-Pegasus such as

- fast response digtal MFC's mounted on top of the process chamber itself to shorten the gas line

- fast APC valve

- fast RF power supply

the etch and deposition cycles may be split into three separate phases, called Delay, Boost and Main. Following the arguments from above, the third phase (Delay) may be thought of as a short delay that ensures a very low pressure (and thus extremely good ion directionality) before the ion bombardment. The standard etches on the Pegasus only make use of up to two phases.

The showerhead that distributes the process gasses inside the plasma source has been changed. With the new design the gas flow resistance in the gas line from MFC to plasma has been reduced. This has very little or no impact on processes that have a continuous gas flow - i.e. processes that are not switched. However, for processes with several gas flows that switch on and off, the switching from one gas flow to another will be much more well defined. This enables us to run Bosch processes with shorter cycles times. Shorter cycles times means smaller scallops and hence lower roughness and better control.

As stated, we believe that only switched processes will be affected by this change. Continuous processes such as Process C, Nano1.42, isotropic etches, barc etches or the black silicon recipes are not believed to be noticeably affected.

Click HERE to see a comparison of some the etches before and after the change of the showerhead.

Processing options on the Pegasus

The Pegasus has a lot of advanced processing options.

- Multiplexing: As described above, the multiplexed Bosch process may have the etch or passivation cycle each split into three separate phases: Delay, Boost and Main.

- Ramping:Using the ramp option one can change process parameters linearly over the course of each processing step.

- Process steps: Stich any number of processing steps with different parameters to make one continuous process.

- Hardware: The Pegasus has several hardware settings:

- Spacers : The distance to the plasma source may be changed by using different spacers.

- Baffle and funnel: The funnel inside the chamber helps to focus the plasma/ions towards the electrode. They may be taken out but don't expect this option to be part of the parameters that you can change in your experiments.

This gives an infinite process parameter space....