Specific Process Knowledge/Lithography/ZEP520A

These tests are currently in progress and this page thus under construction. If you have questions to the process or wish to use this e-beam resist, please contact Tine Greibe at tigre@danchip.dtu.dk.

Process Flow

Test of ZEP resist; a positive e-beam resist from ZEON.

| Equipment | Process Parameters | Comments | Initials and date |

|---|---|---|---|

| Pretreatment | |||

| 4" Si wafers | No Pretreatment | TIGRE, 23-04-2014 | |

| Spin Coat | |||

| Spin Coater Manual, LabSpin, A-5 | ZEP520A 1:1 E-beam resist

60 sec at various spin speed. Acceleration 4000 s-2, softbake 2 min at 180 deg Celcius |

Resist poured directly from bottle | TIGRE, 23-04-2014 |

| Characterization | |||

| Ellipsometer VASE B-1 | 9 points measured on 100 mm wafer | ZEP program used; measured at 70 deg only | TIGRE, 23-04-2014 |

| E-beam Exposure | |||

| JEOL 9500 E-beam writer, E-1 | Dosepattern 14nm - 100nm,

dose 120-280 muC/cm2 |

Virtual chip mark height detection | TIGRE, 23-04-2014 |

| Development | |||

| Fumehood, D-3 | 60 sec in ,

60 sec rinse in IPA, N2 Blow dry |

Agitation (by hand) while developing | TIGRE, XX-04-2014 |

| Characterization | |||

| Zeiss SEM Supra 60VP, D-3 | TIGRE, ??-04-2014 | ||

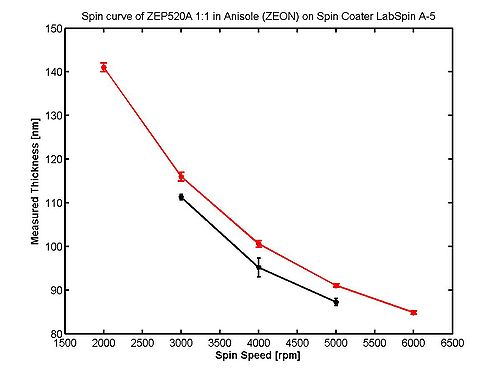

Spin Curve

This spin curve data performed with ZEP520A1:1 bottle opened 13-01-2014 (i.e. approximately 3 month old).

The thickness is measured on VASE Ellipsometer using a simple Cauchy model for a transparent polymer on Si. The measurements are performed at one incidence angle (70 degrees) only. 9 points on each 4" wafer has been measured; the standard deviation thus representing the homogeinity of the film on the 4" wafers.

| AllResist AR-P 6200/2 spinning on Spin Coater: Manual LabSpin A-5, TIGRE, 23-04-2014 | ||||||

|---|---|---|---|---|---|---|

| Spin Speed [rpm] | Acceleration [1/s2] | Thickness [nm] | St Dev | |||

| 3000 | 4000 | |||||

| 4000 | 4000 | |||||

| 5000 | 4000 | |||||