Specific Process Knowledge/Lithography/EBeamLithography/JEOL JBX-9500FSZ/SDFJDFIntro

Job file preparation for JEOL 9500

Introduction

In order to write a pattern with the e-beam system you will have to generate a set of job files. These files are essentially a set of instructions which tell the system what pattern to write, where to place each pattern along with specific writing conditions, exposure dose, alignment conditions and calibration conditions. Apart from this you will naturally also have to generate the pattern you wish to expose.

The JEOL system uses the proprietary EXPRESS (EXposure PREparation System for Scheduling) system for job (schedule) definition. This system uses a compiled architecture in which all files must be prepared in advance and in turn be compiled into an executable job that can then be executed during an exposure session. From a user perspective this means that there is a significant amount of work to be done up front before any exposure can take place. It also means that the learning curve is fairly steep as users have to learn a significant amount about job file preparation in order to carry out even simple exposures. The benefit is however that at runtime, execution is relatively simple with a high likelihood of success, provided that all the preparatory work has been done correctly. At DTU Nanolab it is a strict requirement that all job files are prepared ahead of an exposure session. The JEOL 9500 system is a valuable resource and users must always show up well prepared not to waste tool time on file preparation. Users who squander valuable tool time away due to poor preparation will lose access to the tool.

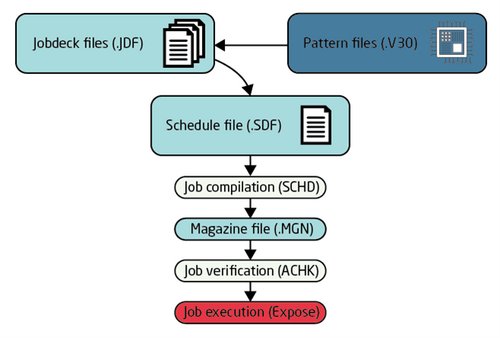

JEOL 9500 file types and generalized flow

In order to execute pattern writing the job must be defined in a Schedule file (SDF) and at least one Jobdeck file (JDF). Both are text files. A pattern file defining the layout is naturally also necessary.

The SDF file contains high level job information and references a Jobdeck file (JDF) for further job information. The SDF file should contain the following information:

- Substrate cassette to use for the exposure

- Beam current and calibration parameter file to use

- Alignment type, if applicable

- Exposure dose

- Beam pitch

- Reference to Jobdeck file (JDF) with pattern placement information

The SDF will reference one or more JDF and each of these should contain the following information:

- Substrate slot ID to expose

- Initial and cyclic calibration path

- Pattern array definition, i.e. number of pattern instances and position

- Alignment mark information if alignment is used

- Reference to pattern file(s) (.V30)

- Dose modulation table if applicable

In this way the SDF is the governing file that calls a number of JDF that in turn will call and specify a pattern or sets of patterns. In order to execute the job the files must be compiled into a magazine file, this is done using the SCHD command in the command prompt on the EBL computer. After compilation the resulting magazine file should be visually validated to some degree to ensure the pattern and placement appears to be correct, this is done with the ACHK program of the system. Finally the job can be executed to expose the substrate(s).

Bear in mind that this is a generalized job flow intended to illustrate the flow with a minimum of complexity. There are several exceptions to the above and several job parameters are interchangeable between SDF and JDF.