Specific Process Knowledge/Thin film deposition/Deposition of Zinc

Zinc deposition

Zinc is tricky to deposit in multiuser vacuum systems because it has a relatively high vapor pressure at low temperatures, which means that once Zn is inside it easily re-evaporates and contaminates films of other materials. Additionally, ZnO that always forms on the surface of Zn is much more difficult to evaporate than the Zn itself, so once the ZnO is gone, the Zn within may evaporate extremely rapidly, making it hard to control the deposition rate. For this reason it is better to use sputtering than evaporation to deposit Zn.

Beyond this, Zn cannot be deposited in systems with a cryo pump, as it will completely clog the cryo pumping system. The best solution is therefore a sputter system that is pumped by a turbo pump and where possible Zn contamination is not a problem for other users.

In the lab at Danchip the only evaporation system with no cryo pump is the Lesker Thermal Evaporator, so this is the only system that is an option for Zn evaporation. We tested it and found that Zn coats every surface in the chamber and re-evaporates during subsequent evaporation of other materials, contaminating the growing film. After a thorough chamber cleaning, we no longer detect Zn in Al or Ag films made in the evaporator. However, this kind of cleaning takes a full working day and while the chamber is used for Zn no other materials can be deposited without contamination. Also, the measurement is made by XPS and may not detect very small amounts of Zn. We are therefore hesitant to use the evaporator for Zn again. If you wish to deposit Zn, please first explore other options with your research partners.

Note that Zn will not adhere to an Si wafer (probably due to SiO2 on the surface). The same is true for a Ti-coated wafer - the Zn did not stick. We were able to deposit Zn on a Ti/Au coated dummy wafer.

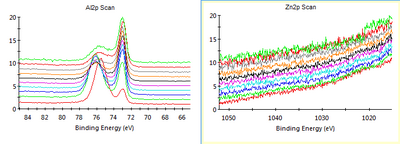

XPS of Al films to detect Zn

XPS was done here at Danchip with 50 eV and 50 ms dwell per scan. The number of scans per element varied as shown below:

Lessons for future thermal deposition of Zn

- It is better to use a crucible rather than a W boat to heat small Zn pellets, as the pellets sometimes jumped out of the boat when they got hot.

- Do the deposition in manual mode as the power level for evaporation was not consistent and the rate was not constant even at a constant power level.

- We needed about 12-13 % power on the Lesker Thermal evaporator to get Zn evaporation. It is best to soak for a long time(e.g., ramping and soaking over about 5-8 minutes).

- The thickness /rate measurement may not have been accurate as the crystal monitor looked irregularly coated after the deposition.

When we asked other labs about Zn evaporation, they mostly said to try to avoid it and perhaps to try to cool the substrate. An employee at the UCSB Nanofabrication Facility had tried thermal evaporation of Zn and says that their chamber now has status as Zn contaminated, but they have had no user complaints and it is now a long time since they did the deposition. Their chamber is mostly used for III-V materials. They used wires of Zn rather than pellets.