|

|

| Line 2: |

Line 2: |

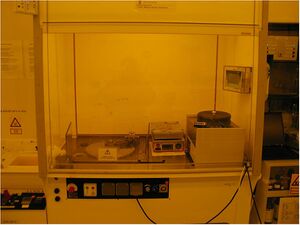

| [[Image:SSEspinner2.jpg|200 × 200px|thumb|The SSE spinner MAXIMUS: positioned in Cleanroom 13.]] | | [[Image:SSEspinner2.jpg|200 × 200px|thumb|The SSE spinner MAXIMUS: positioned in Cleanroom 13.]] |

|

| |

|

| == Process information ==

| |

|

| |

|

| Link to process pages

| |

|

| |

|

| *[[Specific_Process_Knowledge/Photolithography/AZ5214E_standard_resist_-_positive_process|Positive process with AZ5214E resist]]

| |

| *[[Specific_Process_Knowledge/Photolithography/AZ5214E_standard_resist_-_reverse_process|Reverse process with AZ5214E resist]]

| |

| *[[Specific_Process_Knowledge/Photolithography/AZ4562_standard_resist_-_positive_process|Positive process with AZ4562 resist]]

| |

| *[[Specific_Process_Knowledge/E-beam_lithography|E-beam process with ZEP 520A resist]]

| |

|

| |

|

|

| |

|

| |

| Information about resist can be found here:

| |

|

| |

| * [http://groups.mrl.uiuc.edu/dvh/pdf/AZ5214E.pdf AZ5214E ]

| |

| * [http://www.microchemicals.eu/micro/az_4500_series.pdf AZ4562]

| |

| * [http://www.zeonchemicals.com/pdfs/ZEP520A.pdf ZEP520A]

| |

|

| |

|

| ==KS Spinner== | | ==KS Spinner== |

| [[Image:KSspinner.JPG|200×200px|right|thumb|The KS spinner is placed in Cleanroom 3.]] | | [[Image:KSspinner.JPG|200×200px|right|thumb|The KS spinner is placed in Cleanroom 3.]] |

|

| |

|

| == Process information ==

| |

|

| |

| Link to process pages

| |

|

| |

|

| *[[Specific_Process_Knowledge/Photolithography/AZ5214E_standard_resist_-_positive_process|Positive process with AZ5214E resist]]

| |

| *[[Specific_Process_Knowledge/Photolithography/AZ5214E_standard_resist_-_reverse_process|Reverse process with AZ5214E resist]]

| |

| *[[Specific_Process_Knowledge/Photolithography/AZ4562_standard_resist_-_positive_process|Positive process with AZ4562 resist]]

| |

| *[[Specific_Process_Knowledge/Photolithography/SU8|Process with SU8 resist]]

| |

|

| |

|

| Information about resist can be found here:

| |

|

| |

|

| * [http://groups.mrl.uiuc.edu/dvh/pdf/AZ5214E.pdf AZ5214E ]

| |

| * [http://www.microchemicals.eu/micro/az_4500_series.pdf AZ4562]

| |

| * [http://microchem.com/pdf/SU-82000DataSheet2000_5thru2015Ver4.pdf SU8 2005]

| |

| * [http://microchem.com/pdf/SU-82000DataSheet2025thru2075Ver4.pdf SU8 2075]

| |

|

| |

|

| ==Manual Spinner( Polymers)== | | ==Manual Spinner( Polymers)== |

| [[Image:Opticoat.jpg|200×200px|right|thumb|The Manual Spinner(Polymers) is placed in fumehood in Cleanroom 3.]] | | [[Image:Opticoat.jpg|200×200px|right|thumb|The Manual Spinner(Polymers) is placed in fumehood in Cleanroom 3.]] |

|

| |

|

| The Manual Spinner(Polymers), Opticoat SB20+, from SSE Sister Semiconductor Equipment, are dedicated for spinning of imprint polymers, e-beam resist in small batches, SU8 resist and other polymers with extra addictive like color, nano particles etc.

| |

|

| |

| There are 2 hotplates with temperature range up to 250C, placed in the same fumehood, which can be used for baking before/after spinning.

| |

|

| |

|

| |

| '''The user manual(s), quality control procedure(s) and results and contact information can be found in LabManager:'''

| |

| Equipment info in [http://labmanager.danchip.dtu.dk/function.php?module=Machine&view=view&mach=251 LabManager]

| |

|

| |

|

| == Process information ==

| |

|

| |

| Link to process pages

| |

|

| |

|

| ==SÜSS Spinner-Stepper== | | ==SÜSS Spinner-Stepper== |

| [[Image:Gamma_2M.jpg|200×200px|right|thumb|The SÜSS Spinner-Stepper is placed in Stepper room.]] | | [[Image:Gamma_2M.jpg|200×200px|right|thumb|The SÜSS Spinner-Stepper is placed in Stepper room.]] |

|

| |

|

| This spinner is dedicated for spinning DUV resists. The spinner is fully automatic and can run up to 25 substrates in a batch 4", 6", and 8" size. The machine is equipped with the 3 resist lines, a automatic syringe system and a solvent line for cleaning and back-side rinse.

| |

|

| |

|

| |

| '''The user manual(s), quality control procedure(s) and results and contact information can be found in LabManager:'''

| |

| Equipment info in [http://labmanager.danchip.dtu.dk/function.php?module=Machine&view=view&mach=279 LabManager]

| |

|

| |

| Information about resist can be found here:

| |

|

| |

| * Bottom Anti Reflection Coating (BARC)[http://www.brewerscience.com/products/arc/dry-etch-arc-coatings/248nm-products/duv42s DUV 42S-6 ].

| |

| *[[Media:Datasheet_DUV42S.pdf |Datasheet DUV42S-6]].

| |

| *Positive DUV resist for spinning in 300-600 thickness range [[Media:M230Y_PSM_annular_130C_PEB.pdf|KRF M230Y]].

| |

|

| |

| == Process information ==

| |

|

| |

|

| Link to process pages

| |

|

| |

|

| ==Equipment performance and process related parameters== | | ==Equipment performance and process related parameters== |