Specific Process Knowledge/Thin film deposition/Deposition of Gold: Difference between revisions

→Au deposition: removed physimeca |

|||

| Line 15: | Line 15: | ||

! Sputter ([[Specific Process Knowledge/Thin film deposition/Lesker|Lesker]]) | ! Sputter ([[Specific Process Knowledge/Thin film deposition/Lesker|Lesker]]) | ||

! Sputter ([[Specific Process Knowledge/Thin film deposition/Cluster-based multi-chamber high vacuum sputtering deposition system|Sputter-system Metal-Oxide (PC1) and Sputter-system Metal-Nitride (PC3)]]) | ! Sputter ([[Specific Process Knowledge/Thin film deposition/Cluster-based multi-chamber high vacuum sputtering deposition system|Sputter-system Metal-Oxide (PC1) and Sputter-system Metal-Nitride (PC3)]]) | ||

! Sputter coater [[Specific Process Knowledge/Thin film deposition/Sputter coater#Sputter coater 03|(Sputter coater 03)]] | ! Sputter coater [[Specific Process Knowledge/Thin film deposition/Sputter coater#Sputter coater 03|(Sputter coater 03)]] | ||

! Sputter coater [[Specific Process Knowledge/Thin film deposition/Sputter coater#Sputter coater 04|(Sputter coater 04)]] | ! Sputter coater [[Specific Process Knowledge/Thin film deposition/Sputter coater#Sputter coater 04|(Sputter coater 04)]] | ||

| Line 24: | Line 23: | ||

| Sputter deposition of Au | | Sputter deposition of Au | ||

| Sputter deposition of Au | | Sputter deposition of Au | ||

| Sputter deposition of Au | | Sputter deposition of Au | ||

| Sputter deposition of Au | | Sputter deposition of Au | ||

| Line 31: | Line 29: | ||

! Pre-clean | ! Pre-clean | ||

|Ar ion source | |Ar ion source | ||

| | | | ||

|RF Ar clean | |RF Ar clean | ||

|RF Ar clean | |RF Ar clean | ||

| | | | ||

| | | | ||

| Line 43: | Line 40: | ||

|10 Å to 5000 Å ** | |10 Å to 5000 Å ** | ||

|10 Å to 5000 Å ** | |10 Å to 5000 Å ** | ||

| | | | ||

| | | | ||

| Line 54: | Line 50: | ||

|Depends on process parameters, 1-10 Å/s | |Depends on process parameters, 1-10 Å/s | ||

|Depends on process parameters | |Depends on process parameters | ||

|Not measured | |Not measured | ||

|Not measured | |Not measured | ||

| Line 77: | Line 72: | ||

*Up to 10x6" or 4" wafers | *Up to 10x6" or 4" wafers | ||

*Many small pieces | *Many small pieces | ||

| | | | ||

*Several smaller samples | *Several smaller samples | ||

| Line 123: | Line 114: | ||

| | | | ||

* Almost any as long as it does not outgas - see cross-contamination sheets in Labmanager | * Almost any as long as it does not outgas - see cross-contamination sheets in Labmanager | ||

| | | | ||

* All samples allowed in the SEM Supra 1 | * All samples allowed in the SEM Supra 1 | ||

| Line 144: | Line 130: | ||

| | | | ||

* Takes approx. 12 minutes to load and transfer samples | * Takes approx. 12 minutes to load and transfer samples | ||

| | | | ||

* Used for gold sputter coating of samples before SEM inspection | * Used for gold sputter coating of samples before SEM inspection | ||

Revision as of 10:31, 21 September 2022

Feedback to this page: click here

Gold can be deposited by e-beam evaporation or sputtering. In the chart below you can compare the different deposition equipment. We also describe the temperature rise on the wafer during gold deposition, the adhesion layers that can be used for gold deposition, the roughness of gold deposited in the Wordentec, and issues with particulates on the gold films in the Temescal and the Wordentec.

Au deposition

Below you can compare the different equipment that allows Au deposition.

| E-beam evaporation (E-beam evaporator Temescal) | E-beam evaporation (Wordentec) | Sputter (Lesker) | Sputter (Sputter-system Metal-Oxide (PC1) and Sputter-system Metal-Nitride (PC3)) | Sputter coater (Sputter coater 03) | Sputter coater (Sputter coater 04) | |

|---|---|---|---|---|---|---|

| General description | E-beam deposition of Au | E-beam deposition of Au | Sputter deposition of Au | Sputter deposition of Au | Sputter deposition of Au | Sputter deposition of Au |

| Pre-clean | Ar ion source | RF Ar clean | RF Ar clean | |||

| Layer thickness | 10 Å to 1 µm * | 10 Å to 5000 Å | 10 Å to 5000 Å ** | 10 Å to 5000 Å ** | ||

| Deposition rate | 0.5-10 Å/s | 1-10 Å/s | Depends on process parameters, 1-10 Å/s | Depends on process parameters | Not measured | Not measured |

| Batch size |

|

|

|

|

|

|

| Allowed materials |

|

|

|

|

|

|

| Comment |

|

|

|

|

|

|

* For thicknesses above 600 nm write to metal@nanolab.dtu.dk to ensure that there will be enough material in the machine.

** For thicknesses above 200 nm write to metal@nanolab.dtu.dk to ensure that there will be enough material in the machine.

Studies of Au deposition processes in the Wordentec

Roughness of Au layers - Roughness of Au layers deposited in the Wordentec

Wafer temperature

The wafer temperature during e-beam deposition of 200 nm Au on six wafers has been measured using thermal labels on the backside of the wafers. The following results were obtained:

| Wafer | Temperature [C] |

|---|---|

| 1 | 48 |

| 2 | 60 |

| 3 | 65 |

| 4 | 71 |

| 5 | 71 |

| 6 | 77 |

The temperatures are accurate within approximately +/- 3C and probably underestimating the actual wafer temperature slightly. It is observed that the wafer temperature increases with each wafer, thus if wafer temperature is of concern it is advised to reduce the number of wafers per run.

Adhesion of Au on Si

The adhesion of gold on Silicon or Silicon with native oxide is not very good. The Si substrate is often deposited an adhesion layer before the gold deposition. A few nm of Chromium or Titanium works well and they react with the Oxygen of Silicon oxide and present a metallic bond with gold. You can also use polymer or organosilane adhesion layers as exemplified by the work in the next section.

For Cr and Ti adhesion layers, a 5 nm to 10 nm thick layer of Cr or Ti is commonly used and it is important to deposit Cr or Ti and then immediately Au. If the vacuum chamber is opened in between, the surface of Cr or Ti will get oxidized and that will give a poor adhesion. If a gold layer needs to be deposited directly on Silicon, then native oxide has to be removed by deep in diluted HF and immediately load the evaporation chamber. And after the deposition, the wafer has to be heated op to get some Au-Si diffusion which improves the adhesion.

Below you can read about using an organosilane adhesion layer.

Thin Au layer using APTMS adhesion layer and sputter system Lesker

For depositing very thin, down to 6nm continuous Au layers on Si/SiO2 substrates. Works also with ALD deposited Al2O3 and TiO2 as substrate.

Adhesion promoter: aminopropyltrimethoxysilane (APTMS). MSDS here.

Adhesion promoter deposition: 3h immersion in 95%IPA, 2.5% H2O, 2.5% APTMS.

NOTE: the APTMS layer is degrading quickly in atmosphere, so deposit it as close to the Au deposition as possible.

Lesker deposition parameters:

| Gun # | Power [W] | Ramp rate [W/s] | Pressure [mtorr] | Atmosphere | Deposition rate [nm/s] |

|---|---|---|---|---|---|

| 2 | 300 | 5 | 3 | Ar | 1 |

NOTE: As a general rule, the lower the pressure and higher the power (i.e. higher the deposition rate), the better.

Film characteristics (5-10 wafers for each thickness):

| Thickness [nm] | Roughness min [nm] | Roughness max [nm] |

|---|---|---|

| 6 | 0.25 | 0.4 |

| 10 | 0.3 | 0.5 |

| 24 | 0.3 | 0.5 |

NOTE: After depositing 10 layers of 10nm each, one on top of each other, the roughness increased to 0.8nm RMS

Work done by Johneph Sukham (@ DTU Fotonik) and Radu Malureanu (@ DTU Fotonik and DTU Nanolab) in 2016-2017.

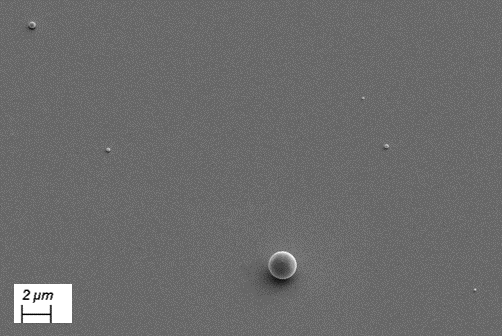

Particulates in e-beam evaporated films

We have found that the amount of particulates on the e-beam evaporated films depends on the deposition parameters. Specifically for gold it is hard to avoid tiny gold droplets on the films, but they can be minimized with careful attention to the sweep parameters, cleanliness of the target, etc.

The droplets appear to be inconsequential for many users, for instance if the Au layer is simply used as an electrical contact. However, for some users it is very important, for instance when the exact resistivity of the Au layer is critical.

You can read more about this issue here.

Quality control of e-beam evaporated TiAu films

| Quality control (QC) for the Temescal | ||||||||||||||||||

Thickness is measured in 5 points with a stylus profiler. |

| Quality control (QC) for Wordentec | ||||||||||||||||

Thickness is measured in 5 points with a stylus profiler. |