LabAdviser/Technology Research/Organic Ice Resists for Electron-Beam Lithography - Instrumentation and Processes/SEM-LEO Customizations for Organic Ice Resists: Difference between revisions

Created page with "'''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/LabAdviser/Technology_Research..." |

No edit summary |

||

| Line 4: | Line 4: | ||

==Overview== | ==Overview== | ||

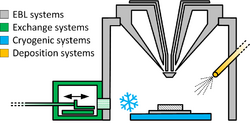

[[image:SketchOIR.png| | [[image:SketchOIR.png|250px|thumb|Schematic depiction of an OIR tool.]] | ||

The standard EBL setup, consisting in a vacuum chamber, a moving stage for sample navigation and an electron-beam gun for imaging and exposure, is not sufficient by itself to provide the necessary conditions to investigate lithography on ice layers: no chamber inlet is available for injecting gas precursors, and sample holders are evidently at room-temperature. | The standard EBL setup, consisting in a vacuum chamber, a moving stage for sample navigation and an electron-beam gun for imaging and exposure, is not sufficient by itself to provide the necessary conditions to investigate lithography on ice layers: no chamber inlet is available for injecting gas precursors, and sample holders are evidently at room-temperature. | ||

The LEO SEM has been provided with a dedicated load-lock and transfer system. Through removable add-ons, it can cool down and warm up, and image or expose samples under cryogenic conditions. Gas can be prepared in the external apparatus and injected into the chamber, and it is possible to monitor the whole process in terms of temperature, pressure, atmosphere composition, and so on. The SEM is now a functional, self-contained lithography system for ice processing. | The LEO SEM has been provided with a dedicated load-lock and transfer system. Through removable add-ons, it can cool down and warm up, and image or expose samples under cryogenic conditions. Gas can be prepared in the external apparatus and injected into the chamber, and it is possible to monitor the whole process in terms of temperature, pressure, atmosphere composition, and so on. The SEM is now a functional, self-contained lithography system for ice processing. | ||

==Gas Injection System== | |||

==Loadlock== | |||

On the left-hand side of the chamber, the load-lock system was implemented to allow exchange operations without condensation of ambient humidity onto cold parts and samples. Since it avoids main chamber ventilation, such a setup maintains stable high vacuum levels inside the SEM, so it can be also useful for regular room-temperature EBL operation, providing a faster and cleaner exchange. | |||

The load-lock has its own turbo and roughing pump, separated from the SEM ones. The roughing pump runs a parallel line to the GIS and can be isolated and operated independently, to pump and exchange precursors. | |||

==Cryogenics== | |||

The cryogenic elements represent the main additions to the inner SEM chamber. A large cold finger and a cryostage are connected together by a copper braid, and mounted onto the same vacuum flange on the right side of the SEM | |||

Revision as of 18:06, 14 June 2018

Feedback to this page: click here

SEM-LEO Customizations for Organic Ice Resists

Overview

The standard EBL setup, consisting in a vacuum chamber, a moving stage for sample navigation and an electron-beam gun for imaging and exposure, is not sufficient by itself to provide the necessary conditions to investigate lithography on ice layers: no chamber inlet is available for injecting gas precursors, and sample holders are evidently at room-temperature.

The LEO SEM has been provided with a dedicated load-lock and transfer system. Through removable add-ons, it can cool down and warm up, and image or expose samples under cryogenic conditions. Gas can be prepared in the external apparatus and injected into the chamber, and it is possible to monitor the whole process in terms of temperature, pressure, atmosphere composition, and so on. The SEM is now a functional, self-contained lithography system for ice processing.

Gas Injection System

Loadlock

On the left-hand side of the chamber, the load-lock system was implemented to allow exchange operations without condensation of ambient humidity onto cold parts and samples. Since it avoids main chamber ventilation, such a setup maintains stable high vacuum levels inside the SEM, so it can be also useful for regular room-temperature EBL operation, providing a faster and cleaner exchange.

The load-lock has its own turbo and roughing pump, separated from the SEM ones. The roughing pump runs a parallel line to the GIS and can be isolated and operated independently, to pump and exchange precursors.

Cryogenics

The cryogenic elements represent the main additions to the inner SEM chamber. A large cold finger and a cryostage are connected together by a copper braid, and mounted onto the same vacuum flange on the right side of the SEM