Specific Process Knowledge/Back-end processing/Polymer Injection Molder/Nozzle: Difference between revisions

| Line 3: | Line 3: | ||

Once the mold has opened, the sample must be ejected from the mold to enable the robot to pick up the sample. This is done by pushing out ejector pins from the mold, which in turn will push out the sample. When samples are picked up reliably by the robot it is usually not necessary to adjust these settings. The settings for the ejector demolding settings are can be found on the 'Mold open' screen: | Once the mold has opened, the sample must be ejected from the mold to enable the robot to pick up the sample. This is done by pushing out ejector pins from the mold, which in turn will push out the sample. When samples are picked up reliably by the robot it is usually not necessary to adjust these settings. The settings for the ejector demolding settings are can be found on the 'Mold open' screen: | ||

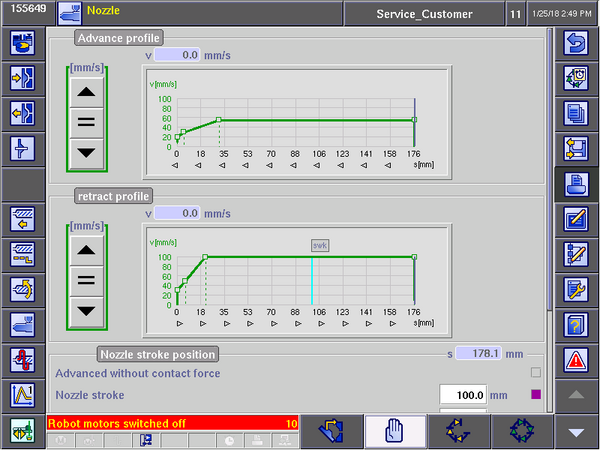

[[File:12-nozzlemove.png|600px|thumb|left| | [[File:12-nozzlemove.png|600px|thumb|left|Movement of the tower (nozzle) is controlled on the 'Tower' screen.]] | ||

<br><br> | <br><br> | ||

*'''Advance profile''': | *'''Advance profile''': This parameter controls the speed profile as the tower moves forward to press the nozzle against the mold inlet port. The default settings work fine for most applications. | ||

<br> | <br> | ||

*'''Retract profile''': | *'''Retract profile''': This parameter controls the speed profile as the tower moves backwards and retracts the nozzle from the mold inlet port. Again, the default settings will work fine for most applications. | ||

<br> | <br> | ||

*''' | *'''Nozzle stroke''': This setting controls how far the nozzle moves back between shots. Usually a value between 40 - 100 mm will work fine. Usually it is only for for highly optimized industrial processes that it makes sense to optimize this parameter (temperature of the inlet port versus time spent on moving the nozzle back and forth). | ||

<br><br><br><br><br><br><br><br> | <br><br><br><br><br><br><br><br> | ||

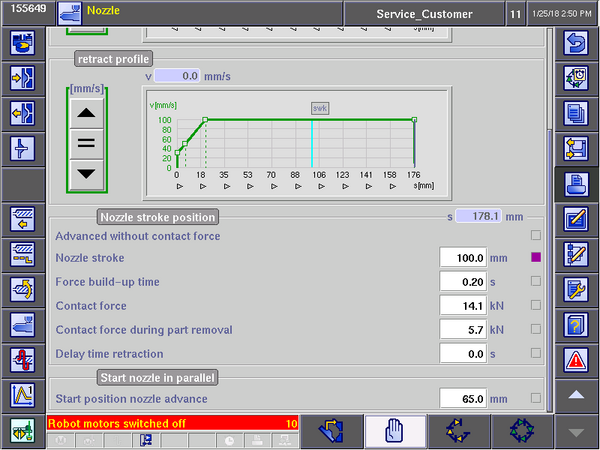

Scrolling down will reveal a few more important settings regarding | Scrolling down will reveal a few more important settings regarding nozzle control: | ||

[[File:09-tower.png|600px|thumb|left|Scrolling down on the ' | [[File:09-tower.png|600px|thumb|left|Scrolling down on the 'Tower' screen reveals additional nozzle settings.]] | ||

<br><br><br><br> | <br><br><br><br> | ||

*'''Ejector shake counter''': If samples are difficult to release from the moving part of the mold, this setting makes it possible to move ejector pins in and out several times to help release the sample in order for the robot to be able to grab the sample. Usually leaving it at 1 works fine, but in some cases it may help to increase the shake counter to 2 or 3. | *'''Ejector shake counter''': If samples are difficult to release from the moving part of the mold, this setting makes it possible to move ejector pins in and out several times to help release the sample in order for the robot to be able to grab the sample. Usually leaving it at 1 works fine, but in some cases it may help to increase the shake counter to 2 or 3. | ||

Revision as of 13:28, 9 February 2018

Nozzle/tower settings

Once the mold has opened, the sample must be ejected from the mold to enable the robot to pick up the sample. This is done by pushing out ejector pins from the mold, which in turn will push out the sample. When samples are picked up reliably by the robot it is usually not necessary to adjust these settings. The settings for the ejector demolding settings are can be found on the 'Mold open' screen:

- Advance profile: This parameter controls the speed profile as the tower moves forward to press the nozzle against the mold inlet port. The default settings work fine for most applications.

- Retract profile: This parameter controls the speed profile as the tower moves backwards and retracts the nozzle from the mold inlet port. Again, the default settings will work fine for most applications.

- Nozzle stroke: This setting controls how far the nozzle moves back between shots. Usually a value between 40 - 100 mm will work fine. Usually it is only for for highly optimized industrial processes that it makes sense to optimize this parameter (temperature of the inlet port versus time spent on moving the nozzle back and forth).

Scrolling down will reveal a few more important settings regarding nozzle control:

- Ejector shake counter: If samples are difficult to release from the moving part of the mold, this setting makes it possible to move ejector pins in and out several times to help release the sample in order for the robot to be able to grab the sample. Usually leaving it at 1 works fine, but in some cases it may help to increase the shake counter to 2 or 3.

- Ejector shake position: This position defines the position the ejector pins move to during shake procedures.

- Mold pause time: This setting is often used when running Variotherm-processes where a delay is required to give the mold time to heat back up to the desired mold temperature before the next cycle can be started. The required time will depend on how cold the mold is at this point in the cycle and the mold temperature setpoint. If the mold has cooled down to 40°C and needs to heat up to 140°C it will usually take several minutes to do so (usually 3-4 minutes). When running constant mold temperature processes, the mold pause time can be set to zero.