Specific Process Knowledge/Back-end processing/Polymer Injection Molder/Eject: Difference between revisions

| Line 5: | Line 5: | ||

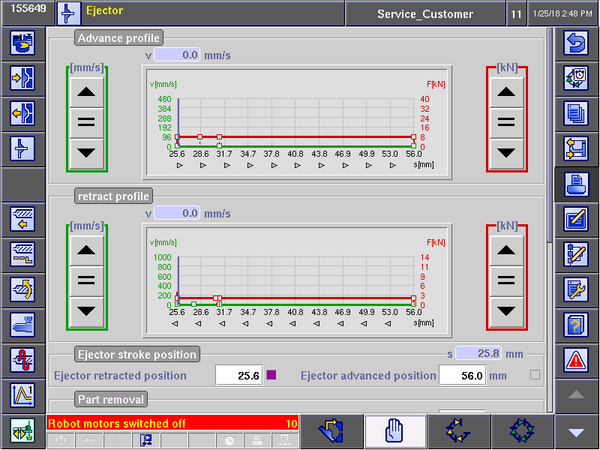

[[File:07a-eject.png|600px|thumb|left|Ejector pin parameters are found on the 'Ejector' screen.]] | [[File:07a-eject.png|600px|thumb|left|Ejector pin parameters are found on the 'Ejector' screen.]] | ||

<br><br> | <br><br> | ||

*''' | *'''Advance profile''': A constant speed can be set using the '=' button or the arrows. Alternatively individual points of the graph can be edited. If samples tend to break during demolding it might help lowering the opening speed. In general the speed should be low towards the end position (fully open position) to avoid violently slamming the mold against the end stop. | ||

<br> | <br> | ||

*''' | *'''Retract profile''': This value defines how far the mold opens. It should generally be avoided to open the mold all the way to the end position, since this causes the mold to bang violently into the end stop. If this happens (you hear a bang every time the mold reaches the open position) decrease the mold stroke position by a few millimeter (e.g. change the stroke from 235 mm to 232 mm). Remember that changing the opening stroke will also change to robot's take-off position, so remember to adjust the take off position accordingly. | ||

<br> | <br> | ||

*''' | *'''Ejector stroke position''': These settings change how the robot is allowed to move around the mold. These settings should generally not be changed (be very careful if you do) to avoid crashing the robot into the mold. | ||

Revision as of 11:57, 8 February 2018

Ejection

Once the mold has opened, the sample must be ejected from the mold to enable the robot to pick up the sample. This is done by pushing out ejector pins from the mold, which in turn will push out the sample. When samples are picked up reliably by the robot it is usually not necessary to adjust these settings. The settings for the ejector demolding settings are can be found on the 'Mold open' screen:

- Advance profile: A constant speed can be set using the '=' button or the arrows. Alternatively individual points of the graph can be edited. If samples tend to break during demolding it might help lowering the opening speed. In general the speed should be low towards the end position (fully open position) to avoid violently slamming the mold against the end stop.

- Retract profile: This value defines how far the mold opens. It should generally be avoided to open the mold all the way to the end position, since this causes the mold to bang violently into the end stop. If this happens (you hear a bang every time the mold reaches the open position) decrease the mold stroke position by a few millimeter (e.g. change the stroke from 235 mm to 232 mm). Remember that changing the opening stroke will also change to robot's take-off position, so remember to adjust the take off position accordingly.

- Ejector stroke position: These settings change how the robot is allowed to move around the mold. These settings should generally not be changed (be very careful if you do) to avoid crashing the robot into the mold.