Specific Process Knowledge/Back-end processing/Polymer Injection Molder/Dosing: Difference between revisions

Created page with "== Dosing (Plasticizing) == After injection it is generally necessary to maintain the injection pressure for a certain time. The time required will depend on processing param..." |

|||

| Line 1: | Line 1: | ||

== Dosing (Plasticizing) == | == Dosing (Plasticizing) == | ||

Plasticizing is the process of dosing polymer pellets into the heating cylinder and press it forwards to melt and circulate (knead) the polymer melt inside the heating cylinder. A major part of the heat required to melt the polymer originates from friction energy during this kneading process. Some polymers are very sensitive to heat and thus most be dosed/plasticized gently to avoid decomposition. If samples turn out yellowish or brown it is likely to be caused to too harsh plasticizing settings. The problem can therefor often be solved by decreasing dosing speed and/or back pressure. | |||

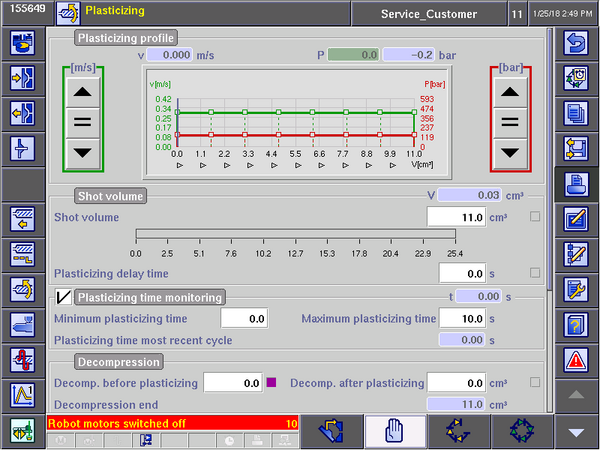

The | The dosing/plasticizing settings are found on the 'Plasticizing' screen: | ||

[[File:05-dosing.png|600px|thumb|left|Holding/after pressure and time are set on the 'Holding pressure' screen]] | [[File:05-dosing.png|600px|thumb|left|Holding/after pressure and time are set on the 'Holding pressure' screen]] | ||

*''' | *'''Dosing speed''': Dosing speed is adjusted by pressing the left (green) '=' sign and entering a value. Alternatively the up/down arrow can be used or the points of the green graph may be edited directly. It is recommended not to increase the speed above ~0,34 m/s. For sensitive polymers it may be necessary to lower the speed. | ||

*''' | *'''Back pressure''': The back pressure is adjusted by pressing the right (red) '=' sign and entering a value, using the arrows or editing the red curve points directly. During dosing the only thing that moves the screw backwards is polymer entering the cylinder and thus pressing the screw backwards. A back pressure is used to "press against" this motion. The higher the back pressure the harder 'kneading' of the polymer. Again, some sensitive polymers might require reduced back pressures to avoid thermal damage (decomposition) of the polymer. | ||

*'''Cushion monitoring''': The cushion is the amount of polymer left in the barrel (heating cylinder) after injection. A small amount must be left in order to be able to maintain a holding pressure. It is recommended to keep the cushion around the center of the interval (i.e. ~1,5 cm<sup>3</sup>). If the cushion is too small the shot volume should be increased and if the cushion is too large the shot volume should be decreased accordingly. Please note that the cushion is pressure dependent. Increasing the holding pressure will decrease the cushion (because the higher the holding pressure the higher compression of the polymer). | *'''Cushion monitoring''': The cushion is the amount of polymer left in the barrel (heating cylinder) after injection. A small amount must be left in order to be able to maintain a holding pressure. It is recommended to keep the cushion around the center of the interval (i.e. ~1,5 cm<sup>3</sup>). If the cushion is too small the shot volume should be increased and if the cushion is too large the shot volume should be decreased accordingly. Please note that the cushion is pressure dependent. Increasing the holding pressure will decrease the cushion (because the higher the holding pressure the higher compression of the polymer). | ||

*'''Shot volume''': If the cushion is too small or too large, adjustments of the shot volume can be quickly made here, as described above. All other settings relevant for dosing (plasticizing) are found on the '''Plasticizing''' screen. | *'''Shot volume''': If the cushion is too small or too large, adjustments of the shot volume can be quickly made here, as described above. All other settings relevant for dosing (plasticizing) are found on the '''Plasticizing''' screen. | ||

Revision as of 14:23, 6 February 2018

Dosing (Plasticizing)

Plasticizing is the process of dosing polymer pellets into the heating cylinder and press it forwards to melt and circulate (knead) the polymer melt inside the heating cylinder. A major part of the heat required to melt the polymer originates from friction energy during this kneading process. Some polymers are very sensitive to heat and thus most be dosed/plasticized gently to avoid decomposition. If samples turn out yellowish or brown it is likely to be caused to too harsh plasticizing settings. The problem can therefor often be solved by decreasing dosing speed and/or back pressure.

The dosing/plasticizing settings are found on the 'Plasticizing' screen:

- Dosing speed: Dosing speed is adjusted by pressing the left (green) '=' sign and entering a value. Alternatively the up/down arrow can be used or the points of the green graph may be edited directly. It is recommended not to increase the speed above ~0,34 m/s. For sensitive polymers it may be necessary to lower the speed.

- Back pressure: The back pressure is adjusted by pressing the right (red) '=' sign and entering a value, using the arrows or editing the red curve points directly. During dosing the only thing that moves the screw backwards is polymer entering the cylinder and thus pressing the screw backwards. A back pressure is used to "press against" this motion. The higher the back pressure the harder 'kneading' of the polymer. Again, some sensitive polymers might require reduced back pressures to avoid thermal damage (decomposition) of the polymer.

- Cushion monitoring: The cushion is the amount of polymer left in the barrel (heating cylinder) after injection. A small amount must be left in order to be able to maintain a holding pressure. It is recommended to keep the cushion around the center of the interval (i.e. ~1,5 cm3). If the cushion is too small the shot volume should be increased and if the cushion is too large the shot volume should be decreased accordingly. Please note that the cushion is pressure dependent. Increasing the holding pressure will decrease the cushion (because the higher the holding pressure the higher compression of the polymer).

- Shot volume: If the cushion is too small or too large, adjustments of the shot volume can be quickly made here, as described above. All other settings relevant for dosing (plasticizing) are found on the Plasticizing screen.