Specific Process Knowledge/Thin film deposition/ALD Picosun R200/ALD multilayers: Difference between revisions

| Line 212: | Line 212: | ||

<gallery caption="" widths=" | <gallery caption="" widths="1000px" heights="1000px" perrow="1"> | ||

image:multilayers222.jpg| Al<sub>2</sub>O<sub>3</sub>/TiO<sub>2</sub> multilayers. | image:multilayers222.jpg| Al<sub>2</sub>O<sub>3</sub>/TiO<sub>2</sub> multilayers. | ||

</gallery> | </gallery> | ||

Revision as of 12:34, 20 May 2016

This page describes non standart recipes including multilayers structures.

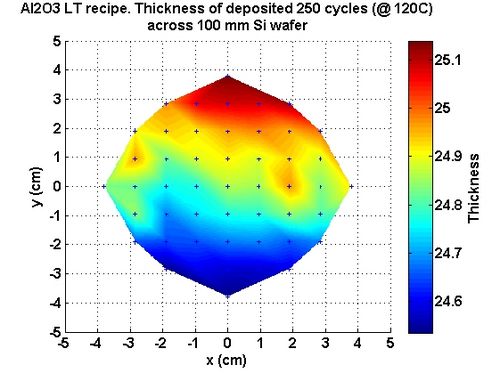

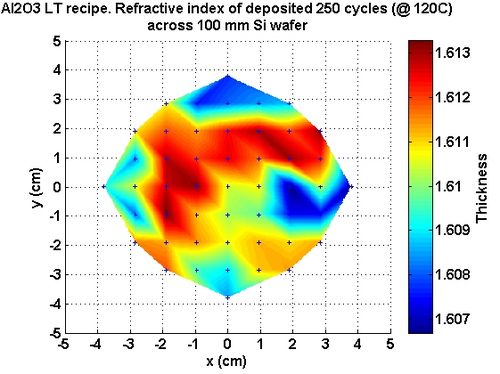

Low temperature deposition of Al2O3

Recipe: Al2O3 LT

Temperature: 80-150 oC

| TMA | H2O | |

|---|---|---|

| Nitrogen flow | 150 sccm | 200 sccm |

| Pulse time | 0.1 s | 0.2 s |

| Purge time | 5.0 s | 10.0 s |

Deposition rate: 0.089 nm/cycle (@120 oC)

This recipe has been developd for fabrication of high quality homogenious optical layers at low temperature. Research related results with this recipe can be found here: LINK

| Al2O3 deposition at 120 oC | |||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

The uniformity, thickness, refractive index has been obtained using Ellipsometer VASE.

-

Measured thickness distribution across 100 mm wafer.

-

Measured refractive index distribution across 100 mm wafer.

Evgeniy Shkondin, DTU Danchip, 2014-2016.

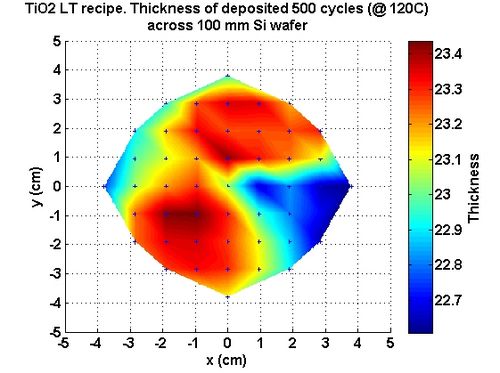

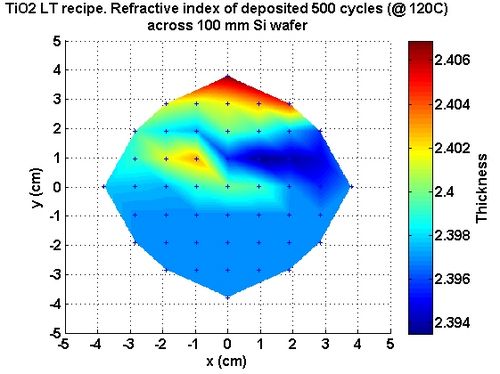

Low temperature deposition of TiO2

Recipe: TiO2 LT

Temperature: 80-150 oC

| TiCl4 | H2O | |

|---|---|---|

| Nitrogen flow | 150 sccm | 200 sccm |

| Pulse time | 0.2 s | 0.2 s |

| Purge time | 10.0 s | 15.0 s |

Deposition rate: 0.048 nm/cycle (@ 120 oC)

This recipe has been developd for fabrication of high quality homogenious optical layers at low temperature. The deposited TiO2 layers are amorphous. Research related results with this recipe can be found here: LINK

| TiO2 deposition at 120 oC | |||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

The uniformity, thickness, refractive index has been obtained using Ellipsometer VASE.

-

Measured thickness distribution across 100 mm wafer.

-

Measured refractive index distribution across 100 mm wafer.

Evgeniy Shkondin, DTU Danchip, 2014-2016.

Low temperature grown multilayers on flat surfaces

Recipe: EMA01

Recipe: EMA02

Recipe: EMA03

Recipe: EMA04

Temperature: 120 oC

-

Al2O3/TiO2 multilayers.

File:Al2O3_TiO2_flat_multilayers.jpg

Evgeniy Shkondin, DTU Danchip, 2014-2016.

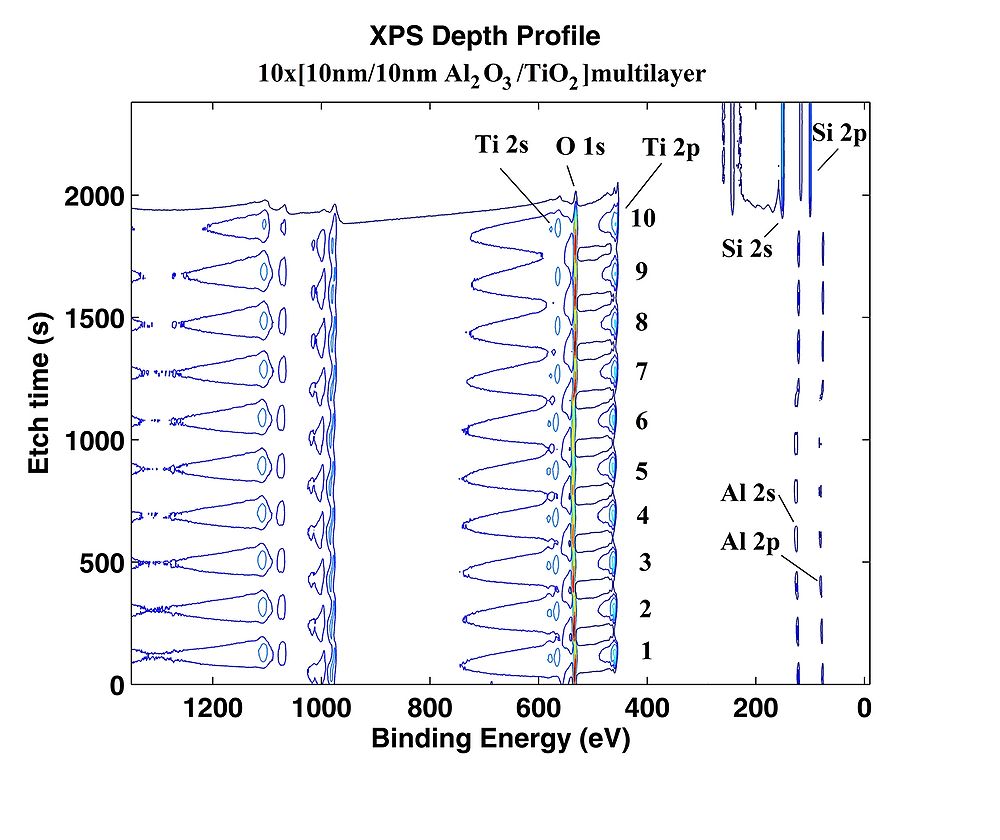

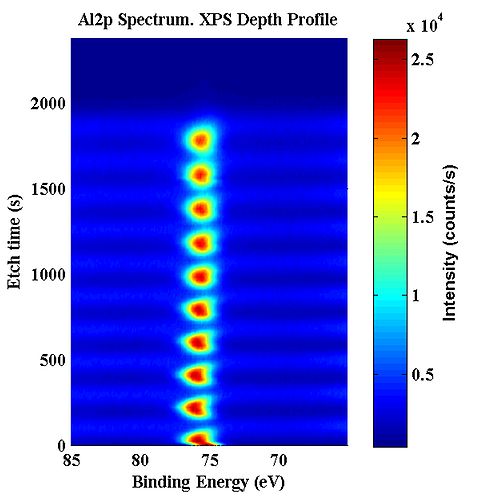

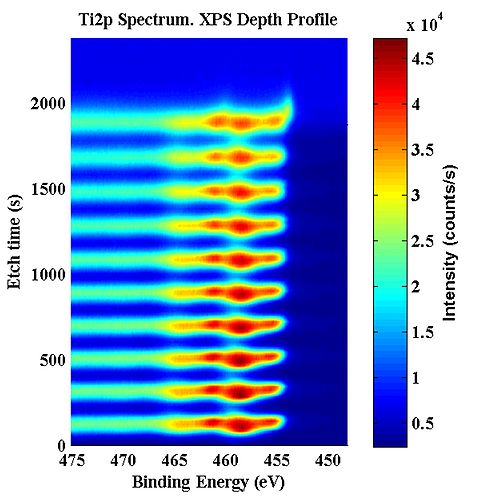

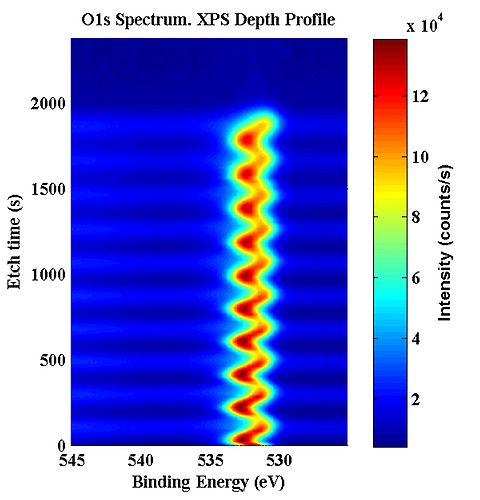

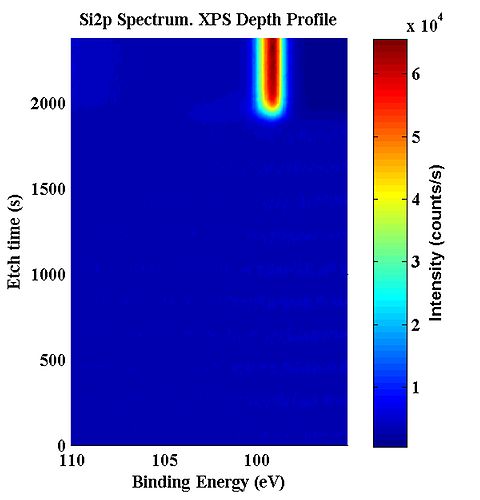

Investigation of chemical composition in multilayers system

Chemical taice analysis has been performed using XPS-ThermoScientific equipment in depth profile mode.

-

Survey scan.

-

Al 2p signal multilayers.

-

Ti 2p signal multilayers.

-

O 1s signal multilayers.

-

Si 2p signal multilayers.

Evgeniy Shkondin, DTU Danchip, 2014-2016.

Al2O3/TiO2 multilayers on high aspect ratio structures

Recipe: Multi T

Temperature: 150 oC

-

Al2O3/TiO2 multilayers grown on silicon trenches.

Evgeniy Shkondin, DTU Danchip, 2014-2016.