Specific Process Knowledge/Etch/DRIE-Pegasus/showerheadchange: Difference between revisions

| Line 80: | Line 80: | ||

! Coil | ! Coil | ||

! Platen | ! Platen | ||

| Hardware | | Hardware | ||

! Runs | ! Runs | ||

! width="100" | Key words | ! width="100" | Key words | ||

|- | |- | ||

! rowspan="6" | Polysilicon etch <!-- recipe name --> | ! rowspan="6" | Polysilicon etch <!-- recipe name --> | ||

! Original | ! Original <!-- step --> | ||

| 30 <!-- chiller temp --> | | 30 <!-- chiller temp --> | ||

! 2.3 <!-- dep time --> | ! 2.3 <!-- dep time --> | ||

Revision as of 10:07, 11 December 2014

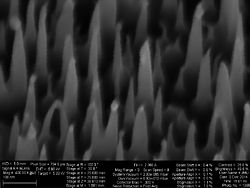

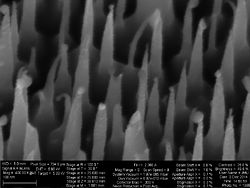

Comparison of continuous processes

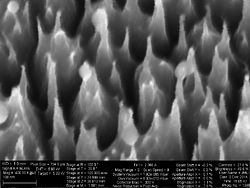

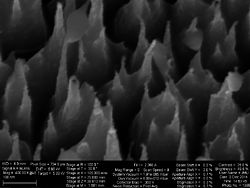

Comparison of switched processes

| Recipe description | Name | Temp. | Deposition step | Etch step | Process observations | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time | Pres. | C4F8 | SF6 | O2 | Coil | Time | Pres. | C4F8 | SF6 | O2 | Coil | Platen | Hardware | Runs | Key words | |||

| Polysilicon etch | Original | 30 | 2.3 | 10 | 50 | 0 | 0 | 600 | 5.0 | 10 | 20 | 60 | 5 | 400 | 40 | - | 1 | |

| Cpoly1 | 30 | 1.2 | 10 | 50 | 0 | 0 | 600 | 5.0 | 10 | 20 | 60 | 5 | 400 | 40 | - | 1 | ||

| Cpoly2 | 30 | 1.4 | 10 | 50 | 0 | 0 | 600 | 5.0 | 10 | 20 | 60 | 5 | 400 | 40 | - | 1 | ||

| Cpoly3 | 30 | 1.6 | 10 | 50 | 0 | 0 | 600 | 5.0 | 10 | 20 | 60 | 5 | 400 | 40 | - | 1 | ||

| Cpoly4 | 30 | 1.8 | 10 | 50 | 0 | 0 | 600 | 5.0 | 10 | 20 | 60 | 5 | 400 | 40 | - | 1 | ||

| Cpoly5 | 30 | 2.0 | 10 | 50 | 0 | 0 | 600 | 5.0 | 10 | 20 | 60 | 5 | 400 | 40 | - | 1 | ||