Specific Process Knowledge/Etch/ICP Metal Etcher/silicon oxide: Difference between revisions

Appearance

| Line 42: | Line 42: | ||

|- | |- | ||

|Profile [<sup>o</sup>] | |Profile [<sup>o</sup>] | ||

|Take a look at the | |Take a look at the images but be aware that the resist profile was not good to begin with. | ||

|- | |- | ||

|Images (click on the image to view a larger image) | |Images (click on the image to view a larger image) | ||

Revision as of 09:45, 17 February 2014

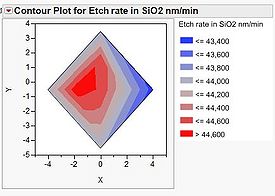

Slow etch of SiO2 with resist as masking material - with direct clamping

This recipe can be used for slow etching of SiO2 with resist as masking material when normal clamping is possible. Normal clamping is prefered because it give the best and most repeatable cooling of the wafer. Here are some test results presented.

| Parameter | Resist mask |

|---|---|

| Coil Power [W] | 200 |

| Platen Power [W] | 25 |

| Platen temperature [oC] | 0 |

| CF4 flow [sccm] | 20 |

| H2 flow [sccm] | 10 |

| Pressure [mTorr] | 3 |