Specific Process Knowledge/Etch/ICP Metal Etcher/Chromium: Difference between revisions

Appearance

No edit summary |

|||

| Line 57: | Line 57: | ||

<br> | <br> | ||

==Chromium etch of hardmask for silicon nitride etching by Anders | ==Chromium etch of hardmask for silicon nitride etching by Anders Simonsen@nbi.ku== | ||

''Added by bghe@Nanolab'' | ''Added by bghe@Nanolab'' | ||

==Chromium etch in ICP metal on a thick glass substrate== | ==Chromium etch in ICP metal on a thick glass substrate== | ||

Revision as of 08:49, 27 September 2022

Feedback to this page: click here

Chromium etch in ICP metal - small substrate using carrier

The Chromium etch was carried out on the following substrate stack: 2" Si wafer with Cr laying in a 6" Si wafer with a 4" recess. The area outside the recess was covered by AZ resist. The work was carried out be Erol Zekovic @Nanotech and BGHE@nanolab

| Parameter | Cr etch |

|---|---|

| Cl2 (sccm) | 65 |

| O2 (sccm) | 15 |

| Pressure (mTorr) | 15 |

| Coil power (W) | 300 |

| Platen power (W) | 15 |

| Temperature (oC) | 50 |

| Spacers (mm) | 100 |

| Etch rate (nm/min) | ~32 (Date: 2014-08-13) |

| Zep520A resist selectivity | NA |

| Comment | Was masked by capton tape |

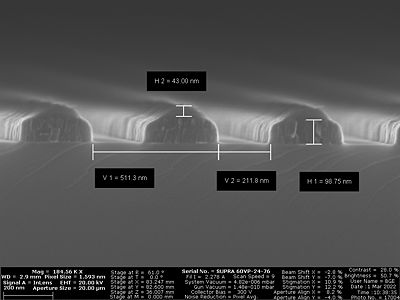

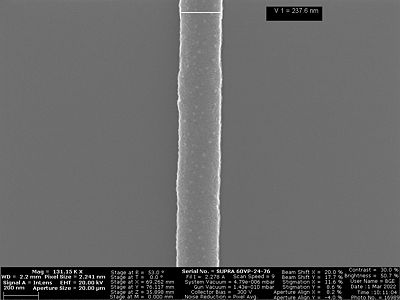

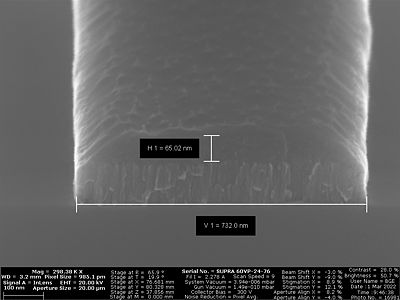

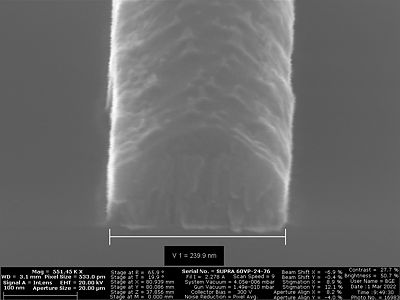

- Etching lines in 100nm Cr with the Cr etch for 3 min with 300 nm DUV resist BGHE@Nanolab Feb 2022

Chromium etch of hardmask for silicon nitride etching by Anders Simonsen@nbi.ku

Added by bghe@Nanolab

Chromium etch in ICP metal on a thick glass substrate

The Chromium etch has ONLY been carried out on the following substrate stack: The Chromium is sputter deposited onto a 2" quartz wafer and patterned by e-beam with Zep520A resist. This 2" QZ wafer is bonded with crystal bond to a 65mmx65mm quartz plate with the thickness: 6.35mm. This QZ plate is bonded to a Si wafer.

| Parameter | Cr etch |

|---|---|

| Cl2 (sccm) | 65 |

| O2 (sccm) | 15 |

| Pressure (mTorr) | 15 |

| Coil power (W) | 300 |

| Platen power (W) | 15 |

| Temperature (oC) | 50 (no back side cooling) |

| Spacers (mm) | 100 |

| Etch rate (nm/min) | ~14 |

| Zep520A resist selectivity | ~0.9 |

| Comment | . |