Specific Process Knowledge/Thin film deposition/Deposition of Gold/Adhesion layers: Difference between revisions

| Line 19: | Line 19: | ||

= Recommendations for nanodevice fabrication = | = Recommendations for nanodevice fabrication = | ||

== Nano-optic devices == | |||

== Nano-electronic devices == | |||

= Adhesion layer impact on Au �film stability with temperature = | = Adhesion layer impact on Au �film stability with temperature = | ||

Revision as of 11:13, 14 August 2018

Adhesion layers

The deposition of metal thin-film structures on dielectric or semiconductor substrates is important in a wide range of micro/nanofabrication applications, including plasmonics, multilayer structures for photonic structures and metamaterials, organic transistors, substrates for graphene growth and field effect devices based on 2D materials and carbon nanotubes. Noble metals such as Au, Ag, and Pt are often used for the fabrication of these structures. Noble metals are preferred for their high thermal and electrical conductivities, strong and unique optical resonances in the visible and near-infrared (NIR) region of the electromagnetic spectrum due to the resonant response of their free electrons to the electric field of light, and chemical inertness. However, their chemical inertness is also a problem during the fabrication process, because the layers adhere poorly to the substrate, leading to different phenomena like delamination, peeling and deterioration of device performance over time.

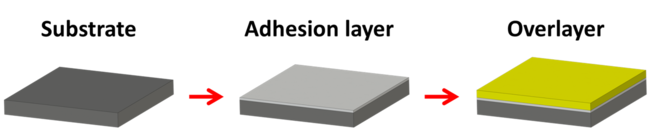

An empiric approach has been applied to the adhesion enhancement, leading to the application of extremely thin adhesion layers between the substrate and the noble metal films. The most used of these adhesion layers are transition metals like Ti and Cr, but the advantages of using these materials as adhesion layers are poorly understood. Fig. 1 represents the simplified adhesion layer model usually used in the micro and nanofabrication community for a generic bilayer system. In this model, the adhesion layer and the noble metal over-layer are deposited sequentially by PVD and are considered to be completely uniform and in perfect contact. Ti and Cr are known to be more chemically reactive than noble metals and thereby increase the adhesion as they chemically bind to the substrate. However, the model does not include any layer-layer interaction. Moreover, it is considered to be independent of the thin-film thickness. Due to the continuous miniaturization of structures and devices, the total metal thin-film thicknesses have reached tens of nanometers, with the thickness of the over-layer approaching the one of the adhesion layer. In these conditions it is unclear if the simplified model is still adequate.

Here the characterization work carried out on two main thin-film systems, Cr/Au and Ti/Au stacks, is presented.

Adhesion layer effect on Au thin films

Effect on Au �film morphology, grain size and texture

Bilayer chemical composition and elemental distribution

Adhesion layer effect on bilayer thin-�film electrical resistivity

Adhesion layer model

Recommendations for nanodevice fabrication

Nano-optic devices

Nano-electronic devices

Adhesion layer impact on Au �film stability with temperature

allic bond with gold. 5 nm to 10 nm thick of Cr or Ti is commonly used and it is important to deposit Cr or Ti and then immediately Au. If the vacuum chamber is opened in between, the surface of Cr or Ti will get oxidized and that will give a poor adhesion. If a gold layer needs to be deposited directly on Silicon, then native oxide has to be removed by deep in diluted HF and immediately load the evaporation chamber. And after the deposition, the wafer has to be heated op to get some Au-Si diffusion which improves the adhesion.