Specific Process Knowledge/Back-end processing/Polymer Injection Molder/SwitchOver: Difference between revisions

Created page with "== Switch-over type == The switch-over type is a very important setting. This setting defines when the injection-phase is done and thus when the machine will continue to the ..." |

|||

| Line 3: | Line 3: | ||

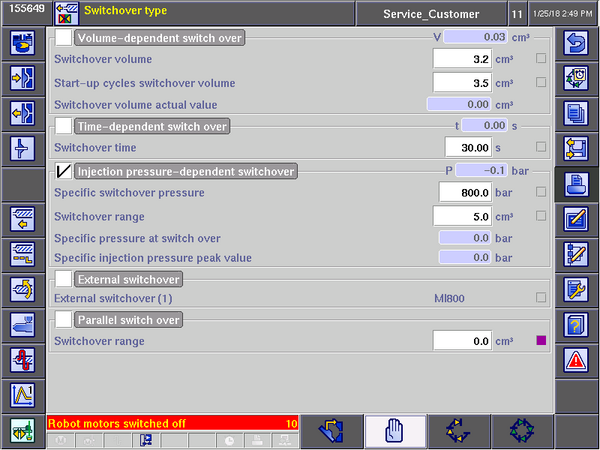

The switch-over type is a very important setting. This setting defines when the injection-phase is done and thus when the machine will continue to the next phase of the injection molding cycle (after pressure / holding pressure). Since this setting defines when we consider injection is done it significantly affect the properties of the produced sample, in particular filling. The switch-over setting are found on the 'Switchover type' screen (which is a sub-icon of the 'Inject' icon): | The switch-over type is a very important setting. This setting defines when the injection-phase is done and thus when the machine will continue to the next phase of the injection molding cycle (after pressure / holding pressure). Since this setting defines when we consider injection is done it significantly affect the properties of the produced sample, in particular filling. The switch-over setting are found on the 'Switchover type' screen (which is a sub-icon of the 'Inject' icon): | ||

[[File:03-switchover.png|600px|thumb|left| | [[File:03-switchover.png|600px|thumb|left|On the 'Switchover type' screen it's possible to select between volume, time, pressure, external and parallel switchover]] | ||

<br> | <br> | ||

*The injection velocity can be adjusted in several ways. One can tap the ''''='''' sign to enter a constant velocity or alternatively use the up/down arrows to move the curve up and down. For more complicated injection speed profiles it is also possible to tap the curve to enter the graphical curve editor where the number and position of individual data points can be edited. This makes it possible to make custom injection speed profiles. | *The injection velocity can be adjusted in several ways. One can tap the ''''='''' sign to enter a constant velocity or alternatively use the up/down arrows to move the curve up and down. For more complicated injection speed profiles it is also possible to tap the curve to enter the graphical curve editor where the number and position of individual data points can be edited. This makes it possible to make custom injection speed profiles. | ||

*The 'Specific injection pressure limit' is an upper safety limit that can be set to protect the mold and/or shim (e.g. if using shims that are soft and thus prone to deformation). Note that '''this setting does not in any way ''set'' the injection pressure'''. It is only an upper safety limit that will not be exceeded. | *The 'Specific injection pressure limit' is an upper safety limit that can be set to protect the mold and/or shim (e.g. if using shims that are soft and thus prone to deformation). Note that '''this setting does not in any way ''set'' the injection pressure'''. It is only an upper safety limit that will not be exceeded. | ||

*The 'Minimum injection time' is usually set around 0-0,05 sec and 'Max. injection time' around 5-8 times the actual injection time. The actual injection time can be seen in the blueish/gray filed just over the max injection time setpoint (in this case it says 0.00 sec because no sample has been produced yet). Actual injection times are usually around 0,2 to 2 seconds so the 'Max. injection time' can typically be set to 1,0 - 15 seconds. | *The 'Minimum injection time' is usually set around 0-0,05 sec and 'Max. injection time' around 5-8 times the actual injection time. The actual injection time can be seen in the blueish/gray filed just over the max injection time setpoint (in this case it says 0.00 sec because no sample has been produced yet). Actual injection times are usually around 0,2 to 2 seconds so the 'Max. injection time' can typically be set to 1,0 - 15 seconds. | ||

Revision as of 15:49, 25 January 2018

Switch-over type

The switch-over type is a very important setting. This setting defines when the injection-phase is done and thus when the machine will continue to the next phase of the injection molding cycle (after pressure / holding pressure). Since this setting defines when we consider injection is done it significantly affect the properties of the produced sample, in particular filling. The switch-over setting are found on the 'Switchover type' screen (which is a sub-icon of the 'Inject' icon):

- The injection velocity can be adjusted in several ways. One can tap the '=' sign to enter a constant velocity or alternatively use the up/down arrows to move the curve up and down. For more complicated injection speed profiles it is also possible to tap the curve to enter the graphical curve editor where the number and position of individual data points can be edited. This makes it possible to make custom injection speed profiles.

- The 'Specific injection pressure limit' is an upper safety limit that can be set to protect the mold and/or shim (e.g. if using shims that are soft and thus prone to deformation). Note that this setting does not in any way set the injection pressure. It is only an upper safety limit that will not be exceeded.

- The 'Minimum injection time' is usually set around 0-0,05 sec and 'Max. injection time' around 5-8 times the actual injection time. The actual injection time can be seen in the blueish/gray filed just over the max injection time setpoint (in this case it says 0.00 sec because no sample has been produced yet). Actual injection times are usually around 0,2 to 2 seconds so the 'Max. injection time' can typically be set to 1,0 - 15 seconds.