Specific Process Knowledge/Thin Film deposition/ALD/Al2O3 deposition using ALD: Difference between revisions

No edit summary |

|||

| Line 44: | Line 44: | ||

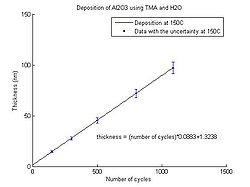

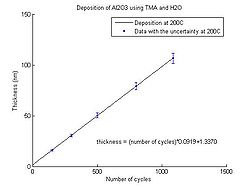

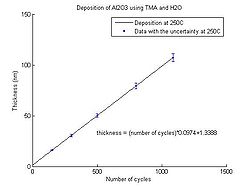

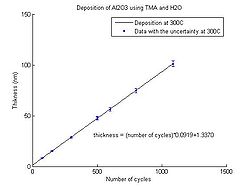

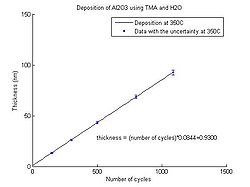

In the graphs below the Al<sub>2</sub>O<sub>3</sub> thickness as function of number of cycles for deposition temperatures between 150 <sup>o</sup>C and 350 <sup>o</sup>C can be seen. From the equations the number of cycles required for a certain thickess can be calculated. | In the graphs below the Al<sub>2</sub>O<sub>3</sub> thickness as function of number of cycles for deposition temperatures between 150 <sup>o</sup>C and 350 <sup>o</sup>C can be seen. From the equations the number of cycles required for a certain thickess can be calculated. | ||

<gallery caption="Aluminium oxide thickness as function of number of cycles" widths="250px" heights="250px" perrow="5"> | <gallery caption="Aluminium oxide thickness as function of number of cycles" widths="250px" heights="250px" perrow="5"> | ||

Revision as of 11:07, 23 June 2017

Feedback to this page: click here

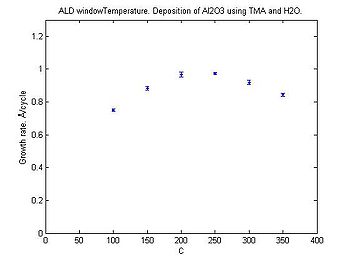

The ALD window for depostion of aluminium dioxide (Al2O3) ranges from 150 oC to 350 oC. XPS measurements shows that at temperatures below 150 oC the Al2O3 layer will be contaminated by unreacted TMA molecules, and at temperatures above 350 oC the TMA decomposes.

All results shown on this page have been obtained using the "AL2O3" recipe on new Si(100) wafers with native oxide:

Al2O3 standard recipe

Recipe: AL2O3

Temperature: 150 oC - 350 oC

| TMA | H2O | |

|---|---|---|

| Nitrogen flow | 150 sccm | 200 sccm |

| Pulse time | 0.1 s | 0.1 s |

| Purge time | 3.0 s | 4.0 s |

Al2O3 deposition rates

The deposition rate for Al2O3 depends on the temperature, see the graph below.

|

|---|

In the graphs below the Al2O3 thickness as function of number of cycles for deposition temperatures between 150 oC and 350 oC can be seen. From the equations the number of cycles required for a certain thickess can be calculated.

- Aluminium oxide thickness as function of number of cycles

-

Temperature 150 oC.

-

Temperature 200 oC.

-

Temperature 250 oC.

-

Temperature 300 oC.

-

Temperature 350 oC.

Evgeniy Shkondin, DTU Danchip, February-March 2014.