Specific Process Knowledge/Characterization/Element analysis: Difference between revisions

| Line 19: | Line 19: | ||

!width="200" |Secondary Ion Mass Spectroscopy | !width="200" |Secondary Ion Mass Spectroscopy | ||

|- | |- | ||

! Technique | |||

|| Non destructive excitation of X-rays in the sample. The elemental analysis is possible because the energy of these photons is characteristic of the element they emitted from. | || Non destructive excitation of X-rays in the sample. The elemental analysis is possible because the energy of these photons is characteristic of the element they emitted from. | ||

|| Destructive method that sputters off surface atoms with heavy ions. | || Destructive method that sputters off surface atoms with heavy ions. | ||

|- | |- | ||

! What elements are detected | |||

|| Any element heavier than boron/carbon | || Any element heavier than boron/carbon | ||

|| Any element | || Any element | ||

|- | |- | ||

! Chemical information | |||

|| None: Only transistions involving inner shell electrons are detected | || None: Only transistions involving inner shell electrons are detected | ||

|| None | || None | ||

|- | |- | ||

! Sample limitations | |||

|| Vacuum compatible | || Vacuum compatible | ||

|| Vacuum compatible | || Vacuum compatible | ||

|- | |- | ||

! Spatial resolution | |||

|| Very precise point-like analysis is possible with SEM electron beam. | || Very precise point-like analysis is possible with SEM electron beam. | ||

|| Limited to what is visible in a camera | || Limited to what is visible in a camera | ||

|- | |- | ||

! Depth resolution | |||

|| The size interaction volume depends on the SEM high voltage and sample density: The higher the SEM high voltage the bigger and deeper the interaction volume. The more dense the material is the smaller is the interaction volume | || The size interaction volume depends on the SEM high voltage and sample density: The higher the SEM high voltage the bigger and deeper the interaction volume. The more dense the material is the smaller is the interaction volume | ||

|| Depth profiling is | || Depth profiling is | ||

|- | |- | ||

! Detection limit | |||

|| Approximately 1 % atomic | || Approximately 1 % atomic | ||

|| Down to 1 ppb for many elements | || Down to 1 ppb for many elements | ||

Revision as of 12:24, 28 January 2008

You can make detailed analysis on the elemental composition and distribution in a sample with 3 instruments at Danchip. The Leo SEM and FEI SEM are both equipped with an X-ray detector that allows you to make elemental analysis by using the technique Energy Dispersive Analysis or EDX. The Atomika SIMS uses a technique called Secondary Ion Mass Spectrometry or SIMS.

Energy Dispersive X-ray analysis

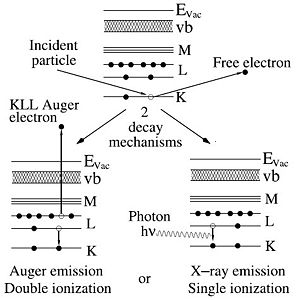

The technique of extracting information from the X-rays generated in a sample that is irradiated with electrons is called energy dispersive X-ray analysis or EDX. (Other acronyms are Energy Dispersive x-ray Spectroscopy, EDS, or Electron Probe Microanalysis, EPMA). The energetic electrons in the incident beam create core level vacancies as they collide with sample atoms electrons in a multiple scattering process. To decay from this excited state photons may be emitted. The energy of these photons is determined by the difference in energy of the shells involved. Since atomic shells are unique for every element so will be the transitions between them. Thus, every element has its own characteristic X-ray spectrum that can be used to determine the elemental composition.

Secondary Ion Mass Spectrometry

When a solid sample is sputtered by primary ions of few keV energy, a fraction of the particles emitted from the target is ionized. Secondary Ion Mass Spectrometry consists of analyzing these secondary ions with a mass spectrometer. Secondary ion emission by a solid surface under ion bombardment supplies information about the elemental, isotopic and molecular composition of its uppermost atomic layers.

| Energy Dispersive X-ray Analysis | Secondary Ion Mass Spectroscopy | |

|---|---|---|

| Technique | Non destructive excitation of X-rays in the sample. The elemental analysis is possible because the energy of these photons is characteristic of the element they emitted from. | Destructive method that sputters off surface atoms with heavy ions. |

| What elements are detected | Any element heavier than boron/carbon | Any element |

| Chemical information | None: Only transistions involving inner shell electrons are detected | None |

| Sample limitations | Vacuum compatible | Vacuum compatible |

| Spatial resolution | Very precise point-like analysis is possible with SEM electron beam. | Limited to what is visible in a camera |

| Depth resolution | The size interaction volume depends on the SEM high voltage and sample density: The higher the SEM high voltage the bigger and deeper the interaction volume. The more dense the material is the smaller is the interaction volume | Depth profiling is |

| Detection limit | Approximately 1 % atomic | Down to 1 ppb for many elements |

SIMS is the most sensitive elemental and isotopic surface analysis technique. The secondary ion yields will vary greatly according to the chemical environment and the sputtering conditions (ion, energy, angle). This can add complexity to the quantitative aspect of the technique.

(detection limit down to ppb level for many elements), high lateral resolution imaging (down to 40 nm), and a very low background that allows high dynamic range (more than 5 decades). This technique is "destructive" by its nature (sputtering of material). It can be applied to any type of material (insulators, semiconductors, metals) that can stay under vacuum.

It allows molecular as well as elemental characterization of the first top monolayer in the static SIMS mode. It allows also the investigation of bulk composition or depth distribution of trace elements in the dynamic SIMS mode, with a depth resolution ranging from one to 20-30 nanometers.

This is why SIMS is one of the most widespread surface analysis techniques for advanced material research.