Specific Process Knowledge/Characterization/XPS/XPS Depth profiling: Difference between revisions

No edit summary |

|||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php?title=Specific_Process_Knowledge/Characterization/XPS/XPS_Depth_profiling click here]''' | |||

=Depth profiling= | =Depth profiling= | ||

Revision as of 09:24, 18 February 2014

Feedback to this page: click here

Depth profiling

The analysis is made on a chosen spot on the sample surface (chosen with the system camera). The technique is, as written above, very surface sensitive and probes only the top nanometers of the sample.

With the ion beam gun on the system an etch of the sample can be done. The system measures the desired spectrum, does an etch step and measures again. A series of etch cycles can be set up, measuring the composition of the sample at different depths (for example at different depth of a film).

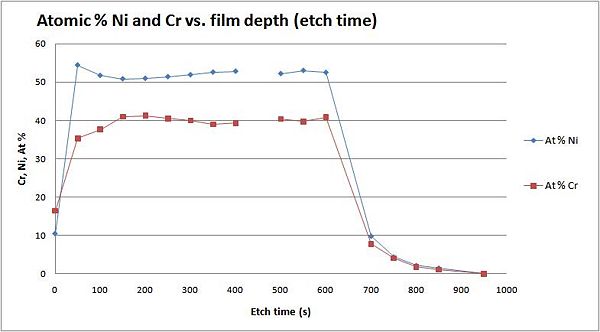

Example: NiCr film

As an illustration, a figure to the left, shows an elemental analysis through a metallic film consisting of Ni and Cr. The metallic layer was about 70 nm thick, and the atomic percentage of Ni and Cr was measured through the layer.

In the graph, you see the atomic % as a function of etch depth, and it is possible to detect that the relationship between Ni and Cr is fairly constant through the metallic film.