Specific Process Knowledge/Etch/Etching of Silicon Oxide/SiO2 etch using ASE/More test with CF4/H2, CHF3 and C4F8/H2 - SiO2 etch: Difference between revisions

| (16 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

= | =Etch tests of Silicon Oxide= | ||

Tests performed by Maria Farinha @DTU Nanolab | Tests performed by Maria Farinha @DTU Nanolab | ||

The gas flows were combined and the following results were achieved. It´s visible that with higher CF<sub>4</sub> the selectivity is not good, so by adding H2, until 1:1, the selectivity improves. Additionally, the uniformity gets slightly worse while going for 1:1 of gas chemistry. | |||

<br> | |||

The recipe CF4lowCP 22.5/22.5 seems to be the only one good enough to use. It is a slow etch recipe, with good selectivity with AZ5214E resist. | |||

{| border="1" cellspacing="2" cellpadding="2" | |||

|-style="background:Black; color:White" | |||

! CF4ICP | |||

|SiO<sub>2</sub> ER (nm/min) | |||

|Uniformity (SiO<sub>2</sub> etch) | |||

|Selectivity (SiO<sub>2</sub>:resist) | |||

|Si<sub>3</sub>N<sub>4</sub> ER (nm/min) | |||

|Si<sub>x</sub>N ER (nm/min) | |||

|- | |||

|45 CF<sub>4</sub> + 0 H<sub>2</sub> | |||

|<center>71.4</center> | |||

|<center>11.7%</center> | |||

|<center>0.74</center> | |||

|<center>-</center> | |||

|<center>-</center> | |||

|- | |||

|35 CF<sub>4</sub> + 10 H<sub>2</sub> | |||

|<center>69</center> | |||

|<center>12.6%</center> | |||

|<center>0.89</center> | |||

|<center>-</center> | |||

|<center>-</center> | |||

|- | |||

|22.5 CF<sub>4</sub> + 22.5 H<sub>2</sub> | |||

|<center>58.6</center> | |||

|<center>13.3%</center> | |||

|<center>1.43</center> | |||

|<center>84.4</center> | |||

|<center>42.9</center> | |||

|- | |||

|} | |||

*The uniformity considers a 100mm wafer, calculated with 5 points. | |||

<br> | |||

{| border="1" cellspacing="2" cellpadding="2" | |||

|-style="background:Black; color:White" | |||

! CF4lowCP | |||

|SiO<sub>2</sub> ER (nm/min) | |||

|Uniformity (SiO<sub>2</sub> etch) | |||

|Selectivity (SiO<sub>2</sub>:resist) | |||

|Si<sub>3</sub>N<sub>4</sub> ER (nm/min) | |||

|Si<sub>x</sub>N ER (nm/min) | |||

|- | |||

|45 CF<sub>4</sub> + 0 H<sub>2</sub> | |||

|<center>24.9</center> | |||

|<center>11.5%</center> | |||

|<center>0.47</center> | |||

|<center>-</center> | |||

|<center>-</center> | |||

|- | |||

|35 CF<sub>4</sub> + 10 H<sub>2</sub> | |||

|<center>22.6</center> | |||

|<center>11.6%</center> | |||

|<center>0.64</center> | |||

|<center>-</center> | |||

|<center>-</center> | |||

|- | |||

|22.5 CF<sub>4</sub> + 22.5 H<sub>2</sub> | |||

|<center>17.8</center> | |||

|<center>13.7%</center> | |||

|<center>1.85</center> | |||

|<center>28</center> | |||

|<center>22.5</center> | |||

|- | |||

|} | |||

<br> | |||

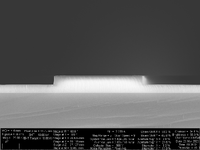

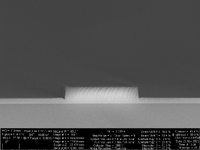

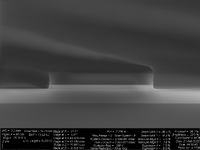

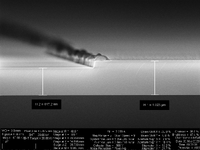

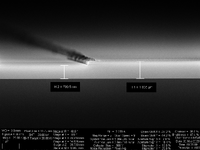

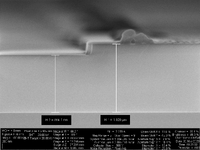

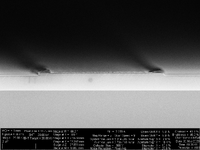

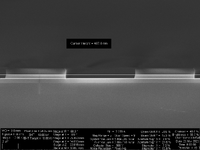

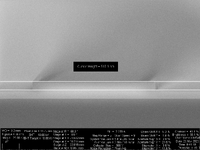

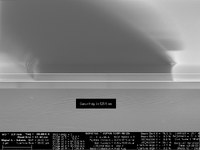

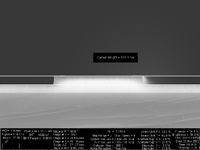

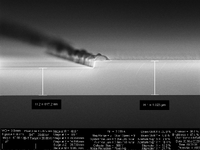

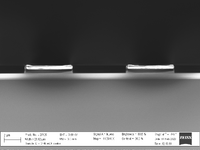

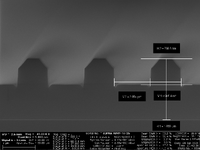

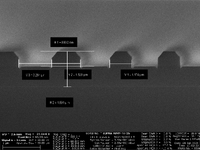

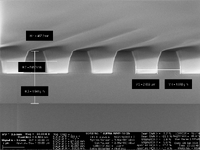

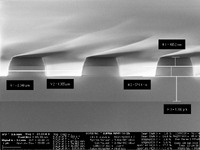

'''Profile pictures of some tests - April 2023''' | |||

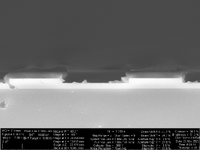

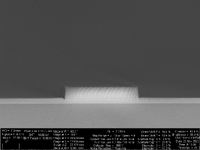

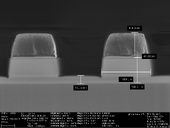

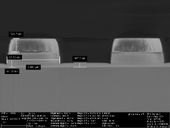

Even in the cases with the resist strip (plasma asher 2 processing for 10/15min), there are some traces of resist left on the edges of the features. <br> | |||

Also, it´s noticeable that the feature profile is trenching, being more evident with faster etch rates. | |||

{| border="1" cellspacing="2" cellpadding="2" | |||

|-style="background:Black; color:White" | |||

|CF4ICP 45 CF<sub>4</sub> + resist strip | |||

|CF4ICP 45 CF<sub>4</sub> / 10 H<sub>2</sub> + resist strip | |||

|CF4ICP 35 CF<sub>4</sub>/ 10 H<sub>2</sub> | |||

|CF4lowCP 45 CF<sub>4</sub>/ 10 H<sub>2</sub> | |||

|CF4lowCP 45 CF<sub>4</sub>/ 0 H<sub>2</sub> + resist strip | |||

|CF4lowCP 35 CF<sub>4</sub>/ 10 H<sub>2</sub> + resist strip | |||

|CF4lowCP 22.5 CF<sub>4</sub>/ 22.5 H<sub>2</sub> + resist strip | |||

|- | |||

|[[File:CF4ICP-45.0c-af-PA-bot-04_1.png|200px]] | |||

|[[File:45.10-af-PA-center-07.png|200px]] | |||

|[[File:CF4lowCP-45.10-22.png|200px]] | |||

|[[File:CF4ICP-35.10-39.png|200px]] | |||

|[[File:low45-0-af-PA-03.png|200px]] [[File:low45-0-af-PA-08.png|200px]] | |||

|[[File:low35-10-af-PA-12.png|200px]] [[File:low35-10-af-PA-06.png|200px]] | |||

|[[File:low22.5-af-PA-08.png|200px]] [[File:low22.5-af-PA-04.png|200px]] | |||

|- | |||

|} | |||

| Line 12: | Line 115: | ||

! '''Date''' | ! '''Date''' | ||

! '''SEM picture''' | ! '''SEM picture''' | ||

! '''Etch rate in SiO2''' | ! '''Etch rate in SiO2''' | ||

! '''Etch rate in resist <br> (AZ5214E inverse)''' | ! '''Etch rate in resist <br> (AZ5214E inverse)''' | ||

! '''Selectivity <br> (SiO2:resist)''' | ! '''Selectivity <br> (SiO2:resist)''' | ||

|- | |- | ||

|- | |- | ||

| Line 26: | Line 125: | ||

|<!--'''Process time'''--> 11:00 min | |<!--'''Process time'''--> 11:00 min | ||

|<!--'''Date'''--> 11/09/2023 | |<!--'''Date'''--> 11/09/2023 | ||

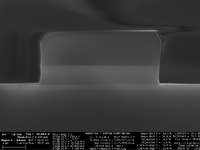

|<!--'''SEM picture'''--> [[File: | |<!--'''SEM picture'''--> [[File:CF4ICP_11min_C_01.png|200px]] [[File:800px-CF4ICP_11min_af_PA_top_01.png|200px]] [[File:800px-CF4ICP_11min_C_03.png|200px]] | ||

|<!--'''Etch rate in SiO2'''--> 68 nm/min <br> +/- 8.5% | |<!--'''Etch rate in SiO2'''--> 68 nm/min <br> +/- 8.5% | ||

|<!--'''Etch rate in resist'''--> 60,2 nm/min <br> +/- 9% | |<!--'''Etch rate in resist'''--> 60,2 nm/min <br> +/- 9% | ||

|<!--'''Selectivity (SiO2:resist)'''--> 1.13 | |<!--'''Selectivity (SiO2:resist)'''--> 1.13 | ||

|- | |- | ||

|- | |- | ||

| Line 41: | Line 136: | ||

|<!--'''Process time'''--> 08:00 min | |<!--'''Process time'''--> 08:00 min | ||

|<!--'''Date'''--> March 2023 | |<!--'''Date'''--> March 2023 | ||

|<!--'''SEM picture'''--> [[File:35. | |<!--'''SEM picture'''--> [[File:200px-35.10_af_ase_04.png|200px]] [[File:200px-35.10_af_PA_bot_03.png|200px]] | ||

|<!--'''Etch rate in SiO2'''--> 69 nm/min <br> +/- 11.1% | |<!--'''Etch rate in SiO2'''--> 69 nm/min <br> +/- 11.1% | ||

|<!--'''Etch rate in resist'''--> 77,1 nm/min <br> +/- 9.4% | |<!--'''Etch rate in resist'''--> 77,1 nm/min <br> +/- 9.4% | ||

|<!--'''Selectivity (SiO2:resist)'''--> 0.9 | |<!--'''Selectivity (SiO2:resist)'''--> 0.9 | ||

|- | |- | ||

|- | |- | ||

| Line 56: | Line 147: | ||

|<!--'''Process time'''--> 08:00 min | |<!--'''Process time'''--> 08:00 min | ||

|<!--'''Date'''--> March 2023 | |<!--'''Date'''--> March 2023 | ||

|<!--'''SEM picture'''--> [[File: | |<!--'''SEM picture'''--> [[File:200px-CF4ICP_45.0c_bf_PA_04.png|200px]] [[File:200px-CF4ICP_45.0c_af_Pa-bot_06.png|200px]] | ||

|<!--'''Etch rate in SiO2'''--> 71.4 nm/min <br> +/- 10.3% | |<!--'''Etch rate in SiO2'''--> 71.4 nm/min <br> +/- 10.3% | ||

|<!--'''Etch rate in resist'''--> 96,5 nm/min <br> +/- 6.0% | |<!--'''Etch rate in resist'''--> 96,5 nm/min <br> +/- 6.0% | ||

|<!--'''Selectivity (SiO2:resist)'''--> 0.74 | |<!--'''Selectivity (SiO2:resist)'''--> 0.74 | ||

|- | |- | ||

|- | |- | ||

| Line 72: | Line 158: | ||

|<!--'''Process time'''--> 08:00 min | |<!--'''Process time'''--> 08:00 min | ||

|<!--'''Date'''--> March 2023 | |<!--'''Date'''--> March 2023 | ||

|<!--'''SEM picture'''--> [[File:45. | |<!--'''SEM picture'''--> [[File:200px-45.10_af_ASE_01.png|200px]] [[File:200px-45.10_af_PA_center_07.png|200px]] | ||

|<!--'''Etch rate in SiO2'''--> 67.8 nm/min <br> +/- 14.9% | |<!--'''Etch rate in SiO2'''--> 67.8 nm/min <br> +/- 14.9% | ||

|<!--'''Etch rate in resist'''--> 88,86 nm/min <br> +/- 4.8% | |<!--'''Etch rate in resist'''--> 88,86 nm/min <br> +/- 4.8% | ||

|<!--'''Selectivity (SiO2:resist)'''--> 0.76 | |<!--'''Selectivity (SiO2:resist)'''--> 0.76 | ||

|- | |- | ||

|- | |- | ||

| Line 88: | Line 169: | ||

|<!--'''Process time'''--> 20:00 min | |<!--'''Process time'''--> 20:00 min | ||

|<!--'''Date'''--> Sept 2023 | |<!--'''Date'''--> Sept 2023 | ||

|<!--'''SEM picture'''--> [[File: | |<!--'''SEM picture'''--> [[File:CF4lowCP_20m_pat_C03.png|200px]] [[File:CF4owCP_20min_af_PA_03.png|200px]] | ||

|<!--'''Etch rate in SiO2'''--> 23.8 nm/min <br> +/- 11% | |<!--'''Etch rate in SiO2'''--> 23.8 nm/min <br> +/- 11% | ||

|<!--'''Etch rate in resist'''--> 20,6 nm/min <br> +/- 19.4% | |<!--'''Etch rate in resist'''--> 20,6 nm/min <br> +/- 19.4% | ||

|<!--'''Selectivity (SiO2:resist)'''--> 1.16 | |<!--'''Selectivity (SiO2:resist)'''--> 1.16 | ||

|- | |- | ||

|- | |- | ||

| Line 103: | Line 180: | ||

|<!--'''Process time'''--> 10:00 min | |<!--'''Process time'''--> 10:00 min | ||

|<!--'''Date'''--> Feb 2023 | |<!--'''Date'''--> Feb 2023 | ||

|<!--'''SEM picture'''--> [[File: | |<!--'''SEM picture'''--> [[File:CF4lowCP_35.10_10.png|200px]] [[File:Low35_10_af_PA_12.png|200px]] | ||

|<!--'''Etch rate in SiO2'''--> 22.65 nm/min <br> +/- 10.2% | |<!--'''Etch rate in SiO2'''--> 22.65 nm/min <br> +/- 10.2% | ||

|<!--'''Etch rate in resist'''--> 35.9 nm/min <br> +/- 10.1% | |<!--'''Etch rate in resist'''--> 35.9 nm/min <br> +/- 10.1% | ||

|<!--'''Selectivity (SiO2:resist)'''--> 0.63 | |<!--'''Selectivity (SiO2:resist)'''--> 0.63 | ||

|- | |- | ||

|- | |- | ||

| Line 119: | Line 191: | ||

|<!--'''Process time'''--> 10:00 min | |<!--'''Process time'''--> 10:00 min | ||

|<!--'''Date'''--> Feb 2023 | |<!--'''Date'''--> Feb 2023 | ||

|<!--'''SEM picture'''--> [[File:CF4lowCP. | |<!--'''SEM picture'''--> [[File:CF4lowCP.right_01.png|200px]] [[File:Low45_0_af_PA_05.png|200px]] | ||

|<!--'''Etch rate in SiO2'''--> 24.9 nm/min <br> +/- 10.1% | |<!--'''Etch rate in SiO2'''--> 24.9 nm/min <br> +/- 10.1% | ||

|<!--'''Etch rate in resist'''--> 52,3 nm/min <br> +/- 7.1% | |<!--'''Etch rate in resist'''--> 52,3 nm/min <br> +/- 7.1% | ||

|<!--'''Selectivity (SiO2:resist)'''--> 0.47 | |<!--'''Selectivity (SiO2:resist)'''--> 0.47 | ||

|- | |- | ||

|- | |- | ||

| Line 135: | Line 202: | ||

|<!--'''Process time'''--> 10:00 min | |<!--'''Process time'''--> 10:00 min | ||

|<!--'''Date'''--> Feb 2023 | |<!--'''Date'''--> Feb 2023 | ||

|<!--'''SEM picture'''--> [[File: | |<!--'''SEM picture'''--> [[File:CF4owCP_20min_af_PA_03.png|200px]] | ||

|<!--'''Etch rate in SiO2'''--> 29,4 nm/min <br> +/- 13.7% | |<!--'''Etch rate in SiO2'''--> 29,4 nm/min <br> +/- 13.7% | ||

|<!--'''Etch rate in resist'''--> 100,6 nm/min <br> +/- 16.5% | |<!--'''Etch rate in resist'''--> 100,6 nm/min <br> +/- 16.5% | ||

|<!--'''Selectivity (SiO2:resist)'''--> 0.29 | |<!--'''Selectivity (SiO2:resist)'''--> 0.29 | ||

|- | |- | ||

|- | |- | ||

| Line 153: | Line 215: | ||

<br> | <br> | ||

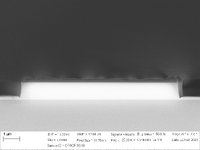

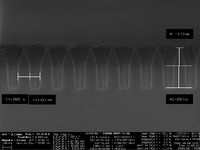

=== | ===Recent results - <span style="background:#FFD850">CF<sub>4</sub> / H<sub>2</sub> tests</span> === | ||

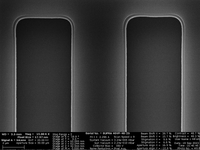

{| border="1" | The following results were processed on chips bonded to a 100mm wafer. They were patterned with 915 UVN resist (DUV negative) and 65nm of BARC. The SiO2 layer was 2um (deposited on the C1 furnace). <br> | ||

(25 jan 2024) | |||

{| border="1" style="text-align: center; width: 320px; height: 200px;" | |||

|colspan="7" style="text-align: center;" style="background:LightGrey" |'''CF4ICP @ 30W platen, 8min''' | |||

|- | |- | ||

|colspan="5" style="text-align: center;" style="background: #efefef;" |'''Values''' | |||

|colspan="1" style="text-align: center;" style="background: #efefef;" |'''SEM pictures''' | |||

|colspan="1" style="text-align: center;" style="background: #efefef;" |'''Comments''' | |||

|- | |- | ||

|- | |- | ||

!Structure size (nm) | |||

|'''structure pitch (nm)''' | |||

|'''SiO2 ER (nm/min)''' | |||

|'''Resist ER (nm/min)''' | |||

|'''Selectivity SiO2/resist''' | |||

| | |||

| | |||

|- | |- | ||

|- | |- | ||

!250 | |||

|500 | |||

|69.36 | |||

|114.38 | |||

|0.61 | |||

|[[File:25.01 CF4ICP 30w 8m-02.png|200px]] | |||

| Across the sample, the resist was fully etched away | |||

|- | |- | ||

|- | |- | ||

!500 | |||

|1000 | |||

|87.04 | |||

|114.38 | |||

|0.76 | |||

|[[File:25.01 CF4ICP 30w 8m-03.png|200px]] | |||

| | |||

|- | |- | ||

!1000 | |||

| | |2000 | ||

| | |98.83 | ||

| | |114.38 | ||

| | |0.86 | ||

| | |[[File:25.01 CF4ICP 30w 8m-04.png|200px]] | ||

| | |||

| | |||

|- | |- | ||

!2000 | |||

|4000 | |||

|100.03 | |||

|114.38 | |||

|0.87 | |||

|[[File:25.01 CF4ICP 30w 8m-05.png|200px]] | |||

| | |||

|- | |- | ||

| | |} | ||

| | |||

{| border="1" style="text-align: center; width: 320px; height: 200px;" | |||

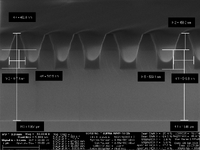

|colspan="7" style="text-align: center;" style="background:LightGrey" |'''CF4lowCP @ 45W platen, 15min''' | |||

| | |||

|- | |- | ||

|colspan="5" style="text-align: center;" style="background: #efefef;" |'''Values''' | |||

|colspan="1" style="text-align: center;" style="background: #efefef;" |'''SEM pictures''' | |||

|colspan="1" style="text-align: center;" style="background: #efefef;" |'''Comments''' | |||

|- | |- | ||

|- | |- | ||

!Structure size (nm) | |||

|'''structure pitch (nm)''' | |||

|'''SiO2 ER (nm/min)''' | |||

|'''Resist ER (nm/min)''' | |||

|'''Selectivity SiO2/resist''' | |||

| | |||

| | |||

|- | |- | ||

|- | |- | ||

!250 | |||

|500 | |||

|33.54 | |||

|33.45 | |||

|1.0 | |||

|[[File:25.01 CF4lowCP 45w 15m-01.png|200px]] | |||

| there was visible redeposition across smaller structures | |||

|- | |- | ||

|- | |- | ||

!500 | |||

|1000 | |||

|35.94 | |||

|30.45 | |||

|1.18 | |||

|[[File:25.01 CF4lowCP 45w 15m-02.png|200px]] | |||

| | |||

|- | |- | ||

!1000 | |||

|2000 | |||

|36.54 | |||

|29.85 | |||

|1.22 | |||

|[[File:25.01 CF4lowCP 45w 15m-03.png|200px]] | |||

| | |||

| | |||

| | |||

| | |||

| | |||

| | |||

| | |||

|- | |- | ||

!2000 | |||

|4000 | |||

|38.09 | |||

|28.65 | |||

|1.33 | |||

|[[File:25.01 CF4lowCP 45w 15m-05.png|200px]] | |||

| | |||

|- | |- | ||

|} | |} | ||

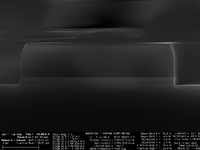

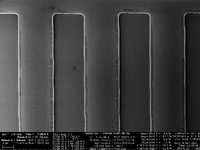

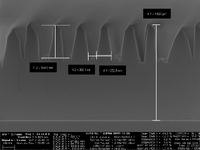

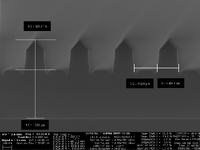

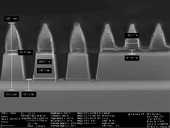

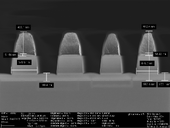

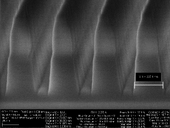

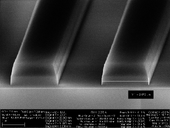

=Etch test of Silicon Nitride= | |||

* The nitride layer deposited was 560nm, on the PECVD4 (recipe: Standard HF SiN with wafer clean, for 1h). <br> | |||

* They were patterned with 750 DUV resist and 65nm of BARC (exposure:355 J/m2, focus:-3.1). <br> | |||

* The following results were processed on chips (2*2cm) bonded to a 100mm dummy wafer. | |||

{| border="1" cellspacing="1" cellpadding="1 | {| border="1" cellspacing="1" cellpadding="1" | ||

! '''Recipe''' | ! '''Recipe''' | ||

! ''' | ! '''Time (min)''' | ||

! '''Date''' | ! '''Date''' | ||

! '''SEM picture''' | ! '''SEM picture''' | ||

! '''Redeposition - top view''' | ! '''Redeposition - top view''' | ||

! '''Etch rate SiN (nm/min)''' | |||

! '''Etch rate | ! '''Etch rate resist (nm/min)''' | ||

! '''Etch rate | ! '''Selectivity <br> (SiN:resist)''' | ||

! '''Selectivity <br> ( | |||

|- | |- | ||

|- | |- | ||

|-style="background:white; color:black" | |-style="background:white; color:black" | ||

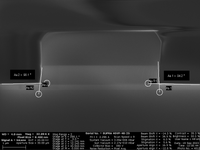

|<!-- ''' | |<!-- '''Recipe name''' --> '''CF4lowCP''' <br> CF<sub>4</sub>= 22.5 sccm <br> H<sub>2</sub>= 22.5 sccm <br> Coil= 150W <br> Platen= '''45W''' <br> Press= 2.5mTorr <br> Temp= 20°C <br> | ||

|<!--'''Process time'''--> 5:00 | |||

|<!--'''Process time'''--> | |<!--'''Date'''--> 29/02<br>-2024 | ||

|<!--'''Date'''--> | |<!--'''SEM picture'''--> [[File:Si3N4 pat3 cf4lowcp- 250.png|170px]] [[File:Si3N4 pat3 cf4lowcp- 500.png|170px]] [[File:Si3N4 pat3 cf4lowcp- 1000.png|170px]] [[File:Si3N4 pat3 cf4lowcp- 2000.png|170px]] | ||

|<!--'''SEM picture'''--> | |<!--'''Redeposition - top view'''--> [[File:SiN cf4lowcp sidewalls 01.png|170px]] [[File:SiN cf4lowcp sidewalls 02.png|170px]] | ||

| | |<!--'''Etch rate in SiO2'''-->250nm- 76,50 <br> <br>500nm- 73,92 <br> <br>1000nm- 73,94 <br> <br>2000nm- 76,50 | ||

|<!--'''Redeposition - top view'''--> [[File: | |<!--'''Etch rate in resist'''-->250nm- 44,98 <br> <br>500nm- 33,52 <br> <br>1000nm- 31,16 <br> <br>2000nm- 25,66 | ||

|<!--'''Selectivity (SiO2:resist)'''-->250nm- 1,70 <br> <br>500nm- 2,21 <br> <br>1000nm- 2,37 <br> <br>2000nm- 2,98 | |||

|<!--'''Etch rate in SiO2'''--> | |||

|<!--'''Etch rate in | |||

|<!--''' | |||

|- | |- | ||

|- | |- | ||

|} | |||

<br clear="all" /> | |||

Latest revision as of 11:54, 29 April 2024

Etch tests of Silicon Oxide

Tests performed by Maria Farinha @DTU Nanolab

The gas flows were combined and the following results were achieved. It´s visible that with higher CF4 the selectivity is not good, so by adding H2, until 1:1, the selectivity improves. Additionally, the uniformity gets slightly worse while going for 1:1 of gas chemistry.

The recipe CF4lowCP 22.5/22.5 seems to be the only one good enough to use. It is a slow etch recipe, with good selectivity with AZ5214E resist.

| CF4ICP | SiO2 ER (nm/min) | Uniformity (SiO2 etch) | Selectivity (SiO2:resist) | Si3N4 ER (nm/min) | SixN ER (nm/min) |

|---|---|---|---|---|---|

| 45 CF4 + 0 H2 | |||||

| 35 CF4 + 10 H2 | |||||

| 22.5 CF4 + 22.5 H2 |

- The uniformity considers a 100mm wafer, calculated with 5 points.

| CF4lowCP | SiO2 ER (nm/min) | Uniformity (SiO2 etch) | Selectivity (SiO2:resist) | Si3N4 ER (nm/min) | SixN ER (nm/min) |

|---|---|---|---|---|---|

| 45 CF4 + 0 H2 | |||||

| 35 CF4 + 10 H2 | |||||

| 22.5 CF4 + 22.5 H2 |

Profile pictures of some tests - April 2023

Even in the cases with the resist strip (plasma asher 2 processing for 10/15min), there are some traces of resist left on the edges of the features.

Also, it´s noticeable that the feature profile is trenching, being more evident with faster etch rates.

Recipes and results - CF4 / H2 tests

Recent results - CF4 / H2 tests

The following results were processed on chips bonded to a 100mm wafer. They were patterned with 915 UVN resist (DUV negative) and 65nm of BARC. The SiO2 layer was 2um (deposited on the C1 furnace).

(25 jan 2024)

Etch test of Silicon Nitride

- The nitride layer deposited was 560nm, on the PECVD4 (recipe: Standard HF SiN with wafer clean, for 1h).

- They were patterned with 750 DUV resist and 65nm of BARC (exposure:355 J/m2, focus:-3.1).

- The following results were processed on chips (2*2cm) bonded to a 100mm dummy wafer.