Specific Process Knowledge/Thin film deposition/Deposition of Tungsten/Evaporation of W in Temescal: Difference between revisions

Created page with "=Deposition of W in Temescal= During the e-beam deposition of Tungsten, extremely bright light and heat are generated! Lower density film than expected due to porosity. Consider using sputtering instead. Power 33W, stable rate, tooling 86%. Measured thickness 20 nm (XRR). <b>Wait for base pressure 3 10-7Torr before start.</b> {| border="2" cellspacing="2" cellpadding="2" colspan="3" |bgcolor="#98FB98" |'''Deposition of Tungsten. Dep. rate: 0.5Å/s, Thickness sp.:..." |

No edit summary |

||

| (6 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Thin_film_deposition/Deposition_of_Tungsten/Evaporation_of_W_in_Temescal click here]''' | |||

<i>This page is written by <b>Evgeniy Shkondin @DTU Nanolab</b> if nothing else is stated. <br> | |||

All images and photos on this page belongs to <b>DTU Nanolab</b>.<br> | |||

The fabrication and characterization described below were conducted in <b>2022 by Evgeniy Shkondin, DTU Nanolab</b>.<br></i> | |||

=Deposition of W in Temescal= | =Deposition of W in Temescal= | ||

This page describes deposition of W in [[Specific_Process_Knowledge/Thin_film_deposition/Temescal|Temescal]]. | |||

During the e-beam deposition of Tungsten, extremely bright light and heat are generated! Lower density film than expected due to porosity. Consider using sputtering instead. | During the e-beam deposition of Tungsten, extremely bright light and heat are generated! Lower density film than expected due to porosity. Consider using sputtering instead. | ||

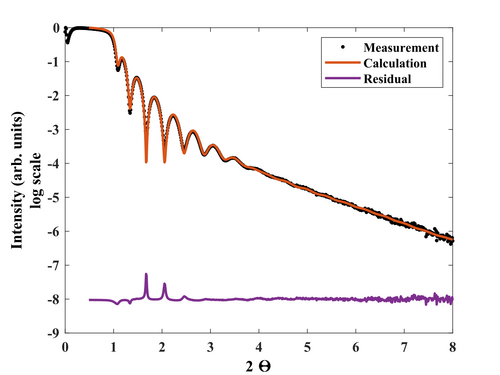

Power 33W, stable rate, tooling 86%. Measured thickness 20 nm (XRR). | Power 33W, stable rate, tooling 86%. Measured thickness 20 nm ([[Specific Process Knowledge/Characterization/XRD/XRD_SmartLab|XRR]]). | ||

<b>Wait for base pressure 3 10-7Torr before start.</b> | <b>Wait for base pressure 3 10-7Torr before start.</b> | ||

| Line 77: | Line 85: | ||

<gallery caption="XRR analysis of e-beam deposited Ta thin film." widths="500px" heights="500px" perrow="1"> | <gallery caption="XRR analysis of e-beam deposited Ta thin film." widths="500px" heights="500px" perrow="1"> | ||

image:eves_20220225_W_Temescal.png| X-ray reflectivity. Measurement and Fit. Tooling 86%. <b>Seems that this deposition suffered from a high oxidation level. (low fitted density of the main Ta layer) or poures formation</b> | image:eves_20220225_W_Temescal.png| [[Specific Process Knowledge/Characterization/XRD/XRD_SmartLab|X-ray reflectivity]]. Measurement and Fit. Tooling 86%. <b>Seems that this deposition suffered from a high oxidation level. (low fitted density of the main Ta layer) or poures formation</b> | ||

</gallery> | </gallery> | ||

Latest revision as of 20:21, 18 February 2023

Feedback to this page: click here

This page is written by Evgeniy Shkondin @DTU Nanolab if nothing else is stated.

All images and photos on this page belongs to DTU Nanolab.

The fabrication and characterization described below were conducted in 2022 by Evgeniy Shkondin, DTU Nanolab.

Deposition of W in Temescal

This page describes deposition of W in Temescal.

During the e-beam deposition of Tungsten, extremely bright light and heat are generated! Lower density film than expected due to porosity. Consider using sputtering instead.

Power 33W, stable rate, tooling 86%. Measured thickness 20 nm (XRR).

Wait for base pressure 3 10-7Torr before start.

| Deposition of Tungsten. Dep. rate: 0.5Å/s, Thickness sp.: 20nm | |||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||

- XRR analysis of e-beam deposited Ta thin film.

-

X-ray reflectivity. Measurement and Fit. Tooling 86%. Seems that this deposition suffered from a high oxidation level. (low fitted density of the main Ta layer) or poures formation