Specific Process Knowledge/Etch/DRIE-Pegasus/Etch 3 dimensional silicon microstructures: Difference between revisions

No edit summary |

No edit summary |

||

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

<!-- Ok, jmli 2020-0120 --> | <!-- Ok, jmli 2020-0120 --> | ||

'''Feedback to this page''': '''[mailto:labadviser@ | <!-- Page reviewed 9/8-2022 jmli --> | ||

<!--Checked for updates on 4/4-2025 - ok/jmli --> | |||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Etch/DRIE-Pegasus/Etch_3_dimensional_silicon_microstructures click here]''' | |||

* ''This work was done by Henri Jansen and Bingdong Chang in 2017;'' | * ''This work was done by Henri Jansen and Bingdong Chang in 2017;'' | ||

Latest revision as of 07:41, 4 April 2025

Feedback to this page: click here

- This work was done by Henri Jansen and Bingdong Chang in 2017;

- This page was last edited by Bingdong Chang 24 October 2017.

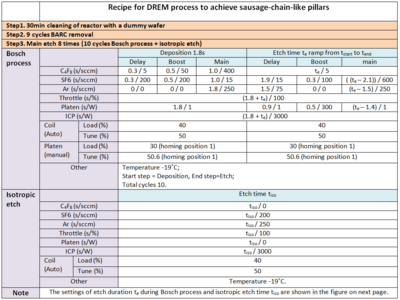

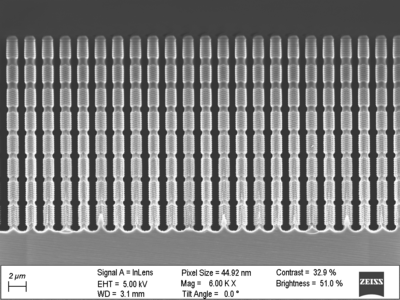

By combining anisotropic Bosch process and isotropic etch process, 3 dimensional structures can be fabricated using DRIE-Pegasus, below is an example to show how 3D "sausage-chain-like" micropillars can be achieved. The patterns were defined with DUV lithography (1µm diameter structures with 2µm pitch size), the resist used was 750nm KRF M230Y positive DUV resist.

- Recipe to achieve sausage-chain-like micropillars

- SEM images of 3D sausage-chain-like micropillars

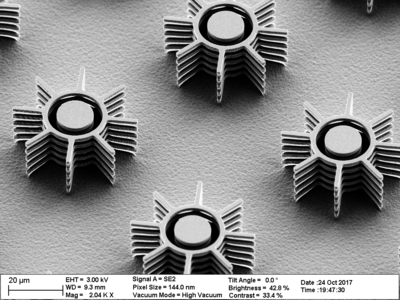

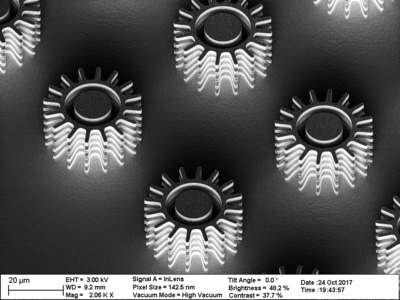

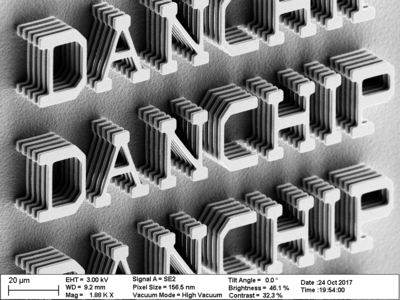

Using the similar methods, other types of 3D microstructures can be fabricated, below are some silicon structures etched with UV resist as a mask, the lithography step was performed with Aligner Maskless, with 1.5µm thick AZ nlof negative resist or 1.5µm AZ 5214 positive resist.

- SEM images of other kinds of 3D silicon microstructures

For more details, please contact Henri Jansen (henrija@dtu.dk) or Bingdong Chang (bincha@dtu.dk)