Specific Process Knowledge/Thin film deposition/ALD Picosun R200/ALD multilayers: Difference between revisions

No edit summary |

|||

| (7 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

This page describes non standart recipes including multilayers structures. | |||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20https://labadviser.nanolab.dtu.dk//index.php?title=Specific_Process_Knowledge/Thin_film_deposition/ALD_Picosun_R200/ALD_multilayers click here]''' | |||

''This page is written by DTU Nanolab internal'' | |||

This page describes non-standart recipes including multilayers structures. They were the first test recipes on the ALD-1 to test the tool functionality and can be used as inspiration. | |||

==Low temperature deposition of Al<sub>2</sub>O<sub>3</sub>== | ==Low temperature deposition of Al<sub>2</sub>O<sub>3</sub>== | ||

| Line 29: | Line 35: | ||

Deposition rate: <b>0.089 nm/cycle </b>(@120 <sup>o</sup>C) | Deposition rate: <b>0.089 nm/cycle </b>(@120 <sup>o</sup>C) | ||

This recipe has been developd for fabrication of high quality homogenious optical layers at low temperature. Research related results with this recipe can be found here: [http://journals.aps.org/prl/abstract/10.1103/PhysRevLett.115.177402 LINK] (Phys. Rev. Lett. 115(17) 2015, 177402) | This recipe has been developd for fabrication of high quality homogenious optical layers at low temperature. Research related results with this recipe can be found here: [http://journals.aps.org/prl/abstract/10.1103/PhysRevLett.115.177402 LINK - requires login] (Phys. Rev. Lett. 115(17) 2015, 177402) | ||

| Line 83: | Line 89: | ||

|} | |} | ||

|} | |} | ||

| Line 129: | Line 133: | ||

Deposition rate: <b>0.048 nm/cycle </b>(@ 120 <sup>o</sup>C) | Deposition rate: <b>0.048 nm/cycle </b>(@ 120 <sup>o</sup>C) | ||

This recipe has been developd for fabrication of high quality homogenious optical layers at low temperature. The deposited TiO<sub>2</sub> layers are amorphous. Research related results with this recipe can be found here: [http://journals.aps.org/prl/abstract/10.1103/PhysRevLett.115.177402 LINK] (Phys. Rev. Lett. 115(17) 2015, 177402) | This recipe has been developd for fabrication of high quality homogenious optical layers at low temperature. The deposited TiO<sub>2</sub> layers are amorphous. Research related results with this recipe can be found here: [http://journals.aps.org/prl/abstract/10.1103/PhysRevLett.115.177402 LINK - requires longin] (Phys. Rev. Lett. 115(17) 2015, 177402) | ||

| Line 226: | Line 230: | ||

===Investigation of chemical composition in multilayers system=== | ===Investigation of chemical composition in multilayers system=== | ||

Chemical tace analysis has been performed using [[Specific_Process_Knowledge/Characterization/XPS | Chemical tace analysis has been performed using [[Specific_Process_Knowledge/Characterization/XPS/K-Alpha|XPS K-Alpha]] equipment in depth profile mode. | ||

<gallery caption="" widths="1000px" heights="1000px" perrow="1"> | <gallery caption="" widths="1000px" heights="1000px" perrow="1"> | ||

Latest revision as of 09:11, 19 June 2023

Feedback to this page: click here

This page is written by DTU Nanolab internal

This page describes non-standart recipes including multilayers structures. They were the first test recipes on the ALD-1 to test the tool functionality and can be used as inspiration.

Low temperature deposition of Al2O3

Recipe: Al2O3 LT

Temperature: 80-150 oC

| TMA | H2O | |

|---|---|---|

| Nitrogen flow | 150 sccm | 200 sccm |

| Pulse time | 0.1 s | 0.2 s |

| Purge time | 5.0 s | 10.0 s |

Deposition rate: 0.089 nm/cycle (@120 oC)

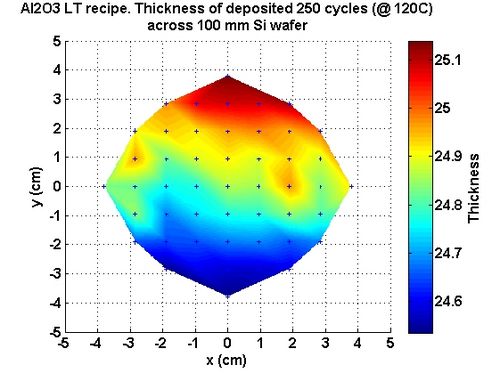

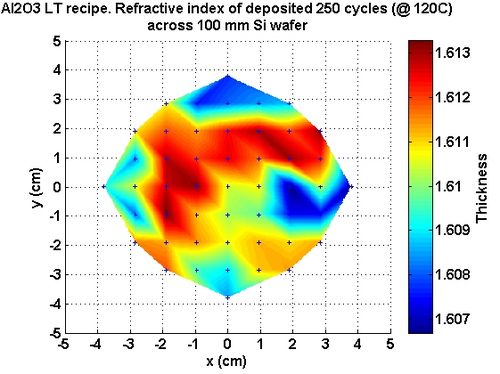

This recipe has been developd for fabrication of high quality homogenious optical layers at low temperature. Research related results with this recipe can be found here: LINK - requires login (Phys. Rev. Lett. 115(17) 2015, 177402)

| Al2O3 deposition at 120 oC | |||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||

The uniformity, thickness, refractive index has been obtained using Ellipsometer VASE.

-

Measured thickness distribution across 100 mm wafer.

-

Measured refractive index distribution across 100 mm wafer.

Evgeniy Shkondin, DTU Nanolab, 2014-2016.

Low temperature deposition of TiO2

Recipe: TiO2 LT

Temperature: 80-150 oC

| TiCl4 | H2O | |

|---|---|---|

| Nitrogen flow | 150 sccm | 200 sccm |

| Pulse time | 0.2 s | 0.2 s |

| Purge time | 10.0 s | 15.0 s |

Deposition rate: 0.048 nm/cycle (@ 120 oC)

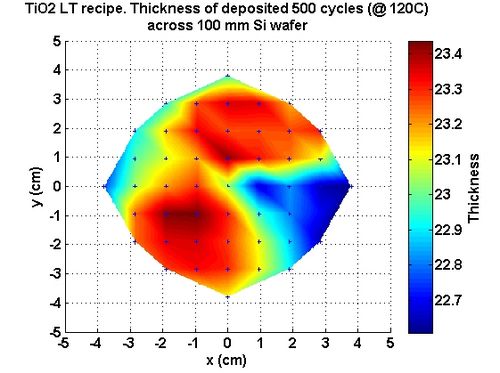

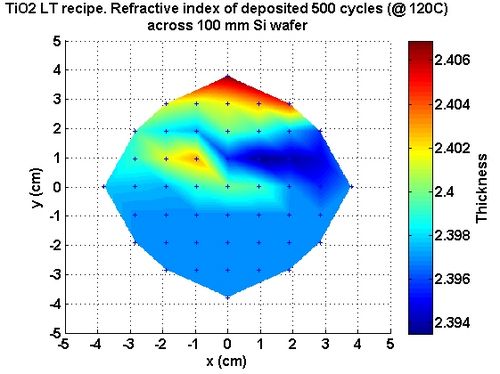

This recipe has been developd for fabrication of high quality homogenious optical layers at low temperature. The deposited TiO2 layers are amorphous. Research related results with this recipe can be found here: LINK - requires longin (Phys. Rev. Lett. 115(17) 2015, 177402)

| TiO2 deposition at 120 oC | |||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

The uniformity, thickness, refractive index has been obtained using Ellipsometer VASE.

-

Measured thickness distribution across 100 mm wafer.

-

Measured refractive index distribution across 100 mm wafer.

Evgeniy Shkondin, DTU Nanolab, 2014-2016.

Low temperature grown multilayers on flat surfaces

Recipe: EMA01

Recipe: EMA02

Recipe: EMA03

Recipe: EMA04

Temperature: 120 oC

All four recipes is based on Al2O3_LT amd TiO2_LT above mentioned low temperature recipes. Optical research based on fabricated Al2O3 and TiO2 multilayers has been published LINK (Phys. Rev. Lett. 115(17) 2015, 177402)

-

Al2O3/TiO2 multilayers.

Evgeniy Shkondin, DTU Danchip, 2014-2016.

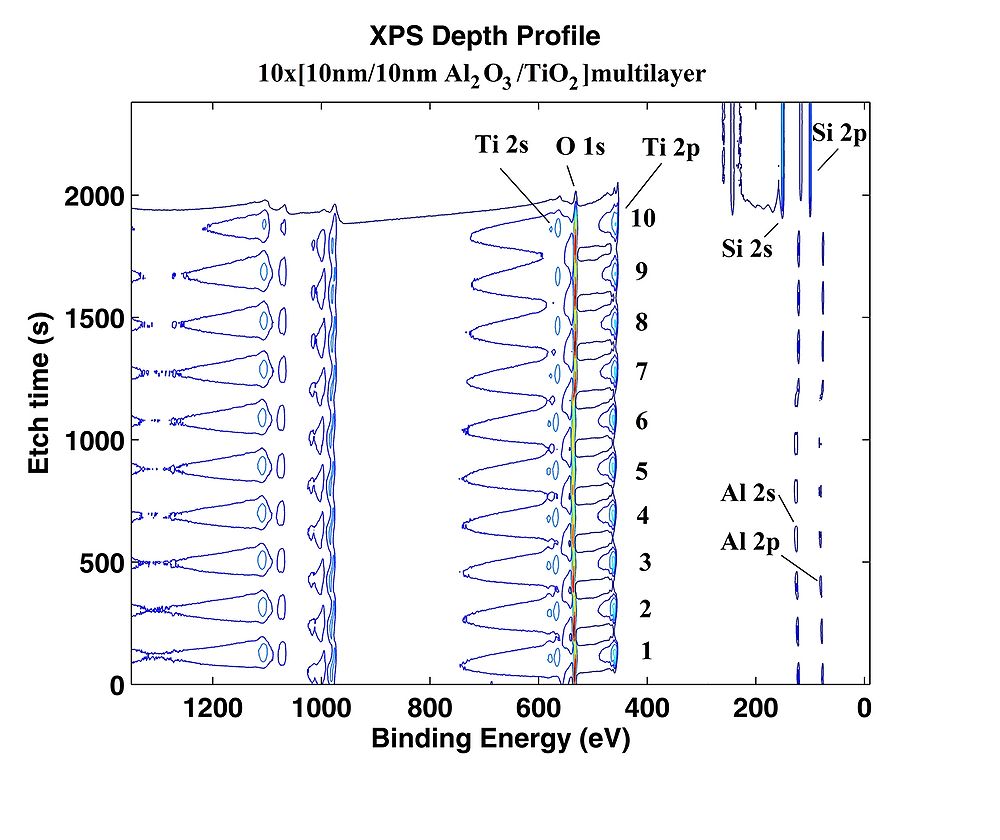

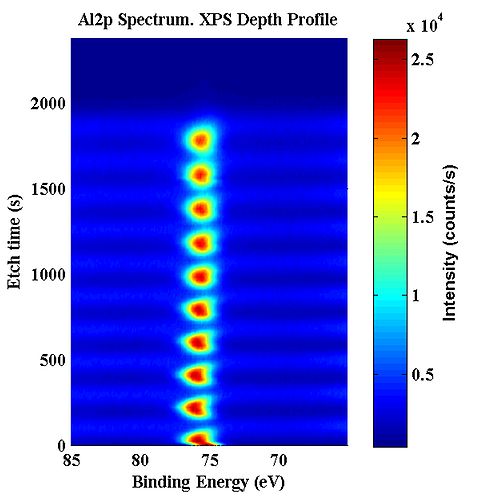

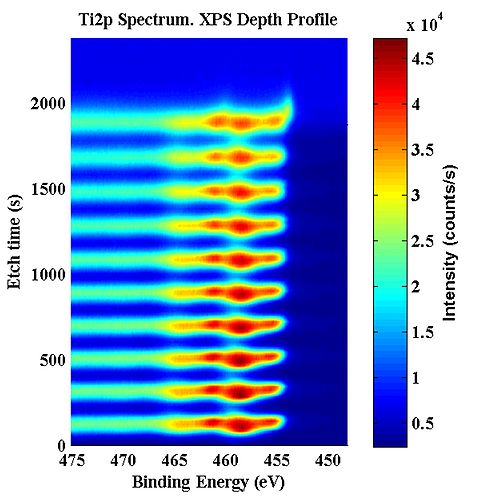

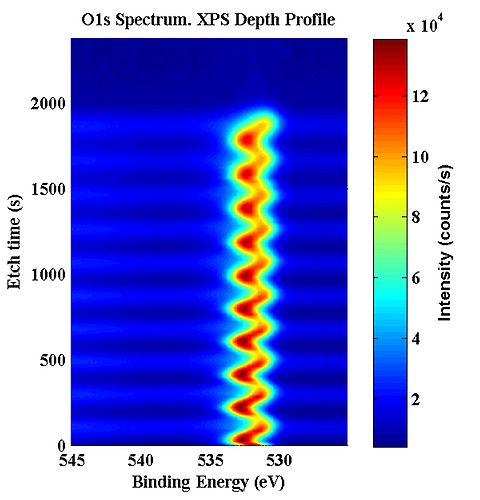

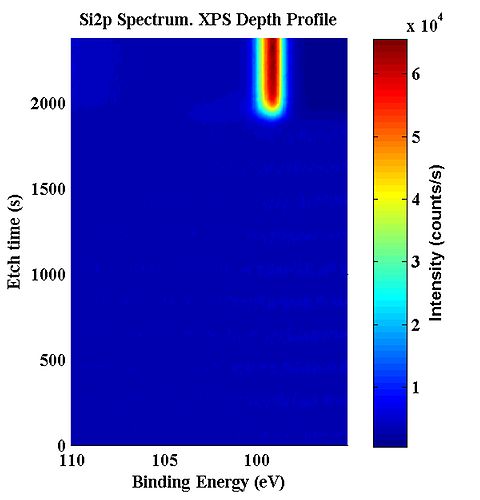

Investigation of chemical composition in multilayers system

Chemical tace analysis has been performed using XPS K-Alpha equipment in depth profile mode.

-

Survey scan.

-

Al 2p signal multilayers.

-

Ti 2p signal multilayers.

-

O 1s signal multilayers.

-

Si 2p signal multilayers.

Evgeniy Shkondin, DTU Danchip, 2014-2016.

Al2O3/TiO2 multilayers on high aspect ratio structures

Recipe: Multi T

Temperature: 150 oC

-

Al2O3/TiO2 multilayers grown on silicon trenches.

Evgeniy Shkondin, DTU Danchip, 2014-2016.