Specific Process Knowledge/Thin film deposition/Temescal/Acceptance Test: Difference between revisions

No edit summary |

|||

| (9 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Knowledge/Thin_film_deposition/Temescal/Acceptance_Test click here]''' | '''Feedback to this page''': '''[mailto:labadviser@danchip.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.danchip.dtu.dk/index.php/Specific_Process_Knowledge/Thin_film_deposition/Temescal/Acceptance_Test click here]''' | ||

<i> Unless otherwise stated, this page is written by <b>DTU Nanolab internal</b></i> | |||

== | ==Temescal acceptance test == | ||

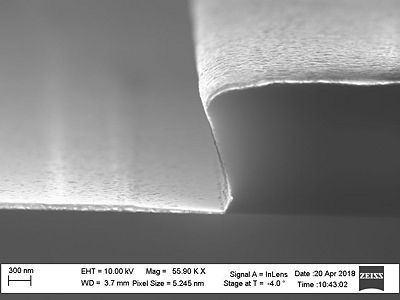

[[File:w26 with resist02.jpg|400px|right|thumb|Si wafer with nLOF resist pattern and 10 nm Ti/100 nm Au on top. The side wall is free of deposition]] | [[File:w26 with resist02.jpg|400px|right|thumb|Si wafer with 1 µm tall nLOF resist pattern and 10 nm Ti/100 nm Au on top. The side wall is free of deposition.]] | ||

In the acceptance test, we tested the vacuum performance, the ion source, and the uniformity of the deposited metal films. | In the acceptance test, we tested the vacuum performance, the ion source, and the uniformity of the deposited metal films. The test was made in March 2018 by Rebecca Ettlinger and Camilla Tingsager. | ||

The uniformity of the ion beam etch was tested on Si wafers with SiO<sub>2</sub> coating of a known thickness. | The uniformity of the ion beam etch was tested on Si wafers with SiO<sub>2</sub> coating of a known thickness. It was measured by ellipsometry. | ||

For metal films | For metal films the thickness was measured with a stylus profiler and for Ti/Ni the sheet resistance uniformity was measured by Capres. | ||

Side wall coverage was evaluated in SEM for Ti/Au films deposited at normal incidence (what most users require, which gives no side-wall deposition) and with various degrees of tilt. | Side wall coverage was evaluated in SEM for Ti/Au films deposited at normal incidence (what most users require, which gives no side-wall deposition) and with various degrees of tilt. | ||

| Line 22: | Line 23: | ||

The thickness uniformity was not tested for the 8" sample holder nor for the tilted sample holder. | The thickness uniformity was not tested for the 8" sample holder nor for the tilted sample holder. | ||

We cannot guarantee that the batch-to-batch thickness reproducibility will always be below 3 % as there may be more drift over longer times. We check the thickness of a Ti/Au deposition every month and ensure that it is within 10 % of the expected value and | We cannot guarantee that the batch-to-batch thickness reproducibility will always be below 3 % as there may be more drift over longer times. We check the thickness of a Ti/Au deposition every month and ensure that it is within 10 % of the expected value and in most cases the variation has been much less than 10 %. You can see the deviation over time in the QC data which is found in LabManager under Documents or ask staff for the detailed data. | ||

== Sheet resistance uniformity == | == Sheet resistance uniformity == | ||

| Line 35: | Line 35: | ||

We achieved an etch rate of up to 1 nm/min for SiO<sub>2</sub>. The etch rate is strongest in the center, about 15-20% higher than at the edges of a 6" wafer. | We achieved an etch rate of up to 1 nm/min for SiO<sub>2</sub>. The etch rate is strongest in the center, about 15-20% higher than at the edges of a 6" wafer. | ||

The reproducibility was quite good with less than 3% variation wafer-to-wafer within a batch and less than 10 % variation between | The reproducibility was quite good with less than 3% variation wafer-to-wafer within a batch and less than 10 % variation between two identical batches. | ||

== Vacuum performance == | == Vacuum performance == | ||

| Line 53: | Line 52: | ||

As expected, the side wall deposition was thicker for 53 ° tilt than for 17 ° tilt. | As expected, the side wall deposition was thicker for 53 ° tilt than for 17 ° tilt. | ||

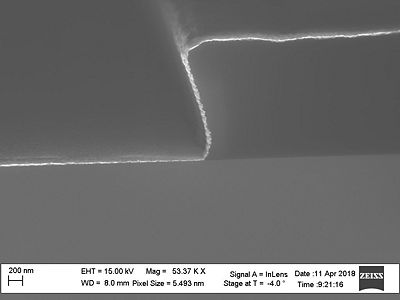

[[File:tilt27_sample1-_01.jpg|400px|thumb|left|17 ° tilt: Side wall deposition of Ti/Au on Si and nLOF resist.]] | [[File:tilt27_sample1-_01.jpg|400px|thumb|left|17 ° tilt: Side wall deposition of Ti/Au on Si and 1 µm tall nLOF resist.]] | ||

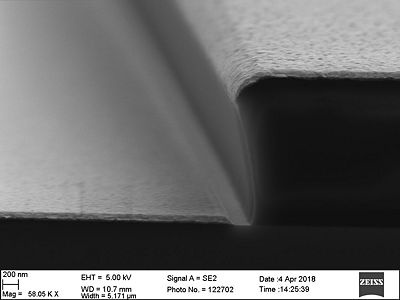

[[File:tilt53_sample2_01.jpg|400px|thumb|right|53 ° tilt: Side wall deposition of Ti/Au on Si and nLOF resist.]] | [[File:tilt53_sample2_01.jpg|400px|thumb|right|53 ° tilt: Side wall deposition of Ti/Au on Si and 1 µm tall nLOF resist.]] | ||

Latest revision as of 10:43, 11 May 2023

Feedback to this page: click here

Unless otherwise stated, this page is written by DTU Nanolab internal

Temescal acceptance test

In the acceptance test, we tested the vacuum performance, the ion source, and the uniformity of the deposited metal films. The test was made in March 2018 by Rebecca Ettlinger and Camilla Tingsager.

The uniformity of the ion beam etch was tested on Si wafers with SiO2 coating of a known thickness. It was measured by ellipsometry.

For metal films the thickness was measured with a stylus profiler and for Ti/Ni the sheet resistance uniformity was measured by Capres.

Side wall coverage was evaluated in SEM for Ti/Au films deposited at normal incidence (what most users require, which gives no side-wall deposition) and with various degrees of tilt.

Full acceptance test report here

Thickness uniformity

The thickness uniformity is good both across a single wafer, from wafer to wafer within a batch of 4 wafers and from batch to batch comparing up to 5 batches. This is ensured by the Hula sample holder, which rotates each individual wafer holder around its axis as well as all four wafer holders around the central axis.

We saw less than 3 % variation across a 6" wafer and comparable or lower variation wafer to wafer and batch to batch.

The thickness uniformity was not tested for the 8" sample holder nor for the tilted sample holder.

We cannot guarantee that the batch-to-batch thickness reproducibility will always be below 3 % as there may be more drift over longer times. We check the thickness of a Ti/Au deposition every month and ensure that it is within 10 % of the expected value and in most cases the variation has been much less than 10 %. You can see the deviation over time in the QC data which is found in LabManager under Documents or ask staff for the detailed data.

Sheet resistance uniformity

The sheet resistance varied less than 2 % across a single 6" Ti/Ni coated wafer and less than 1 % from wafer to wafer comparing a total of 4 wafers made in two different batches.

Note that thickness variation will lead to variation in the sheet resistance, so accurate thickness is important for reproducible sheet resistance values.

Ion source

We achieved an etch rate of up to 1 nm/min for SiO2. The etch rate is strongest in the center, about 15-20% higher than at the edges of a 6" wafer.

The reproducibility was quite good with less than 3% variation wafer-to-wafer within a batch and less than 10 % variation between two identical batches.

Vacuum performance

Pumpdown of the load lock from atmosphere took 15 minutes to below 10-6 Torr, which is the process pressure. Note that this was with a brand new vacuum chamber. The pumping time is slower the more material is deposited inside the machine, as the layers can trap moisture and other gases.

A pumpdown of the whole system took about 1.5 hours to below 10-6 Torr.

More results in the full report.

Side wall deposition on tilted samples

The tilted sample holder was tested with 10 nm Ti/100 nm Au deposition at approx. 27 °, 45 °, and 53 ° to the normal (53 ° is the max tilt variation for a 6" sample holder - we now have a smaller 2" sample holder that can tilt all the way to perpendicular to the evaporation source).

As expected, the side wall deposition was thicker for 53 ° tilt than for 17 ° tilt.