Specific Process Knowledge/Etch/DRIE-Pegasus/Pegasus-4/Slow etch: Difference between revisions

No edit summary |

|||

| (14 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

=The slow etch= | =The slow etch= | ||

''This work is done by Berit Herstrøm @Nanolab | '''''This work is done by Berit Herstrøm @DTU Nanolab, is nothing else is stated''''' <br> | ||

The slow etch is designed to etch slow at low powers to etch thin films and to avoid overheating of samples mounted on a carrier with Capton/polyimide tape | The slow etch is designed to etch slow at low powers to etch thin films and to avoid overheating of samples mounted on a carrier with Capton/polyimide tape | ||

| Line 62: | Line 62: | ||

|- | |- | ||

|Etch rate of Mir resist | |Etch rate in Si | ||

|'''ñm/min | |||

|'''11-13 nm/min (10% load, 4" wafer on 6" carrier) | |||

|- | |||

|Etch rate of Mir resist | |||

|'''~nm/min | |'''~nm/min | ||

|'''~17 nm/min | |'''~17 nm/min | ||

| Line 68: | Line 72: | ||

|- | |- | ||

|Tested etch time without burning the resist | |Tested etch time without burning the resist | ||

|3 min | |3 min (6 min => resist burned) | ||

|30 min | |30 min | ||

|- | |- | ||

| Line 77: | Line 81: | ||

|} | |} | ||

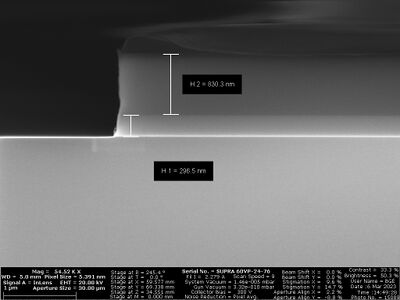

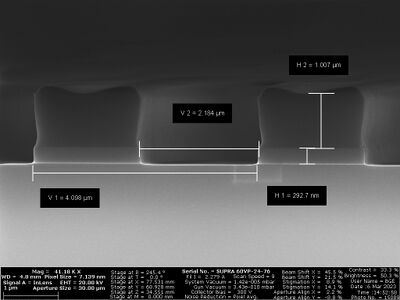

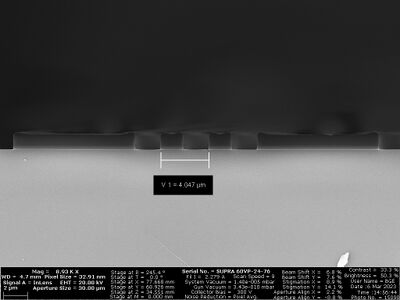

==Etch Profile SEM images== | |||

<gallery caption="Profile of etch for 'Slow Etch2' 12 min, 100mm wafer on 150mm carrier with double side polyimide tape (capton), Si3N4 from LPCVD" widths="300px done by bghe, DTU Nanolab" heights="300px" widths="400px" perrow="3"> | |||

File:C08507_01.jpg | |||

File:C08507_02.jpg | |||

File:C08507_04.jpg | |||

</gallery> | |||

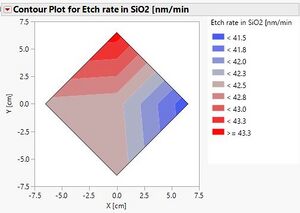

==Etch Uniformity maps== | |||

<br clear="all" /> | <br clear="all" /> | ||

<gallery caption="Map of etch rate measurements for 'Slow Etch'" widths="300px" heights="300px" perrow="2"> | <gallery caption="Map of etch rate measurements for 'Slow Etch'" widths="300px" heights="300px" perrow="2"> | ||

| Line 90: | Line 102: | ||

File:Contour Plot etch rates Si.jpg|Etch rate map of Si etch on 4" wafer (on 6" carrier) | File:Contour Plot etch rates Si.jpg|Etch rate map of Si etch on 4" wafer (on 6" carrier) | ||

</gallery> | </gallery> | ||

==Test section - do not use== | |||

{| class="wikitable" | |||

|+ Caption text | |||

|- | |||

! A !! Header text !! Header text | |||

|- | |||

| Example || Example || Example | |||

|- | |||

| Example || Example || Example | |||

|- | |||

| Example || Example || Example | |||

|} | |||

Latest revision as of 15:36, 1 July 2024

The slow etch

This work is done by Berit Herstrøm @DTU Nanolab, is nothing else is stated

The slow etch is designed to etch slow at low powers to etch thin films and to avoid overheating of samples mounted on a carrier with Capton/polyimide tape

| Parameter | Recipe name: Slow Etch | Recipe name: Slow Etch2 |

|---|---|---|

| Coil Power [W] | 350 | 200 |

| Platen Power [W] | 25 | 50 |

| Platen temperature [oC] | 20 | 20 |

| H2 flow [sccm] | 15 | 15 |

| CF4 flow [sccm] | 30 | 30 |

| Pressure [mTorr] | 3 | 10 |

| Typical results | Slow Etch | Slow Etch2 |

|---|---|---|

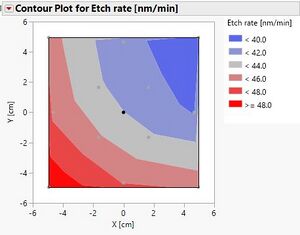

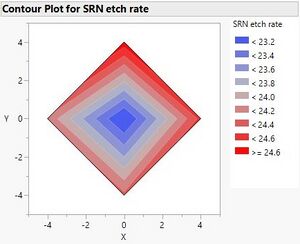

| Etch of SRN | ~43nm/min [measured 39-50 nm/min over a 6" wafer] | 23-25 nm/min [4" on carrier]] |

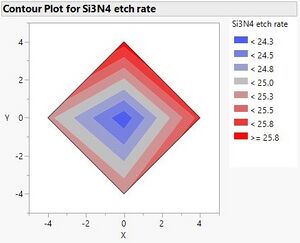

| Etch rate of Si3N4 | ~49 nm/min [4" on carrier] | 24-26 nm/min [4" on carrier] |

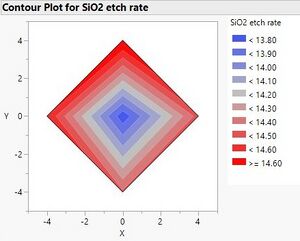

| Etch rate of SiO2 | ~42nm/min [41-43 nm/min over a 6" wafer] | 13.7-14.7 nm/min [4" on carrier] |

| Etch rate in Si | ñm/min | 11-13 nm/min (10% load, 4" wafer on 6" carrier) |

| Etch rate of Mir resist | ~nm/min | ~17 nm/min |

| Tested etch time without burning the resist | 3 min (6 min => resist burned) | 30 min |

| Profile [o] |

Etch Profile SEM images

- Profile of etch for 'Slow Etch2' 12 min, 100mm wafer on 150mm carrier with double side polyimide tape (capton), Si3N4 from LPCVD

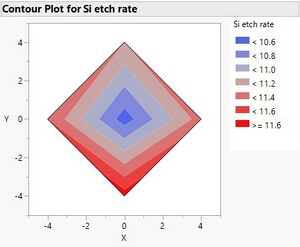

Etch Uniformity maps

- Map of etch rate measurements for 'Slow Etch'

-

Etch rate map of SiO2 etch on 6" wafer

-

Etch rate map of SRN etch on 6" wafer

- Map of etch rate measurements for 'Slow Etch2'

-

Etch rate map of Si3N4 etch on 4" wafer (on 6" carrier)

-

Etch rate map of SRN etch on 4" wafer (on 6" carrier)

-

Etch rate map of SiO2 etch on 4" wafer (on 6" carrier)

-

Etch rate map of Si etch on 4" wafer (on 6" carrier)

Test section - do not use

| A | Header text | Header text |

|---|---|---|

| Example | Example | Example |

| Example | Example | Example |

| Example | Example | Example |