Specific Process Knowledge/Etch/DRIE-Pegasus/Isotropic/mediumiso1: Difference between revisions

No edit summary |

No edit summary |

||

| (3 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Etch/DRIE-Pegasus/Isotropic/mediumiso1 click here]''' | |||

<!--Checked for updates on 30/7-2018 - ok/jmli --> | |||

<!--Checked for updates on 2/10-2020 - ok/jmli --> | |||

<!--Checked for updates on 28/6-2023 - ok/jmli --> | |||

{{contentbydryetch}} | |||

{| border="2" cellpadding="0" cellspacing="0" style="text-align:center;" | {| border="2" cellpadding="0" cellspacing="0" style="text-align:center;" | ||

Latest revision as of 11:31, 28 June 2023

Feedback to this page: click here

Unless otherwise stated, the content of this page was created by the dry etch group at DTU Nanolab

| Date | Substrate Information | Process Information | SEM Images | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Wafer info | Mask | Material/ Exposed area | Tool / Operator | Conditioning | Recipe | Wafer ID | Comments | ||

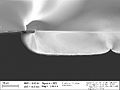

| 9/4-2014 | 4" | travka05 wafer 1.5 µm AZ | Si / 5 % | Pegasus/jmli | 5 minute TDESC clean + MU runs | jml/isotropic/mediumiso1 2:00 minutes | S003961 | ||

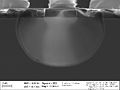

| 6/6-2016 | 6" | travka35 wafer 1.5 µm AZ | Si / 35 % | Pegasus/jmli | standard/danchip/mediumiso1 2:00 minutes | S006534 | |||

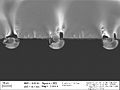

| 6/6-2016 | 6" | travka35 wafer 1.5 µm AZ | Si / 35 % | Pegasus/jmli | standard/danchip/mediumiso1 4:00 minutes | S006535 | |||