Specific Process Knowledge/Characterization/SEM Tabletop 1: Difference between revisions

No edit summary |

No edit summary |

||

| (8 intermediate revisions by 4 users not shown) | |||

| Line 2: | Line 2: | ||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Characterization/SEM_Tabletop_1 click here]''' | '''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Characterization/SEM_Tabletop_1 click here]''' | ||

''All contents by DTU Nanolab staff unless otherwise attributed.'' | |||

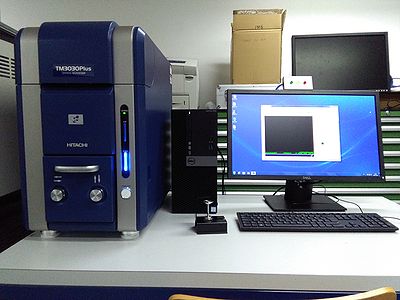

[[image:Tabletop SEM.jpg|400x400px|right|thumb|SEM Tabletop 1 located in | [[image:Tabletop SEM.jpg|400x400px|right|thumb|The SEM Tabletop 1, currently located in building 451, room 913 (as of 2023).]] | ||

=SEM Tabletop 1= | =SEM Tabletop 1= | ||

The SEM Tabletop 1 is a scanning electron microscope. | The SEM Tabletop 1 is a scanning electron microscope. It produces enlarged images of a variety of specimens with good resolution, large depth of field, and minimal sample preparation. | ||

The tabletop SEM has a thermionic filament made of tungsten. | The tabletop SEM was installed at DTU Nanolab in January 2017. It has a thermionic filament made of tungsten and is equipped with two detectors: A secondary electron (SE) detector and a backscatter (BSE) detector.. The chamber is relatively small, so sample loading is fast and easy. The stage is moved manually in the X and Y directions by turning two knobs on the door to the SEM chamber. It is not possible to adjust the height of the stage, and it is not possible to rotate and tilt samples. However, samples can be mounted on pinstubs with a fixed tilt angle. | ||

In this SEM little effort is required to obtain decent SEM images. However, the tabletop SEM has a limited resolution and a limited number of settings you can optimize compared to the other SEMs at Nanolab. For inspection of samples with structures in the micrometer range it is very fast and easy to use. Unlike the other SEMs at Nanolab it is not necessary to take the SEM Tool Package Training course to be authorized to use the tabletop SEM. | |||

The SEM can be operated in different pressure modes: Conductor, standard and charge-up reduction. By increasing the pressure in the chamber it is possible to inspect insulating samples, because the higher density of gas molecules will eliminate the charges at the cost of a slightly reduced resolution. Thus the charge-up reduction mode makes it possible to obtain SEM images of most samples including isolating samples without much sample preparation. If your sample charges a lot or you need higher resolution than what is possible in charge-up reduction mode, you also have the option to coat your sample with gold using [https://labadviser.nanolab.dtu.dk/index.php?title=Specific_Process_Knowledge/Thin_film_deposition/Sputter_coater#Sputter_coater_03 Sputter Coater 03]. | |||

'''The user manual, control instruction, the user APV and contact information can be found in LabManager:''' | '''The user manual, control instruction, the user APV and contact information can be found in LabManager:''' | ||

| Line 54: | Line 44: | ||

|style="background:LightGrey; color:black"| | |style="background:LightGrey; color:black"| | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* | * Building 451 - room 913 | ||

(in the North-East corner of the building, in the basement. | |||

Note that if you enter the building from the East, you enter directly into the basement.) | |||

|- | |- | ||

!style="background:silver; color:black;" align="center" valign="center" width="60"|Performance | !style="background:silver; color:black;" align="center" valign="center" width="60"|Performance | ||

| Line 93: | Line 85: | ||

| style="background:LightGrey; color:black"|Allowed materials | | style="background:LightGrey; color:black"|Allowed materials | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* Any standard cleanroom material | * Any standard cleanroom material, samples from the Laser Micromachining tool and the Polymer Injection Molding tool | ||

* 3D printed polymers | |||

* Pyrolyzed graphite. | |||

* Some biological samples (ask for permission) | * Some biological samples (ask for permission) | ||

|- | |- | ||

|} | |} | ||

Latest revision as of 13:39, 13 June 2023

Feedback to this page: click here

All contents by DTU Nanolab staff unless otherwise attributed.

SEM Tabletop 1

The SEM Tabletop 1 is a scanning electron microscope. It produces enlarged images of a variety of specimens with good resolution, large depth of field, and minimal sample preparation.

The tabletop SEM was installed at DTU Nanolab in January 2017. It has a thermionic filament made of tungsten and is equipped with two detectors: A secondary electron (SE) detector and a backscatter (BSE) detector.. The chamber is relatively small, so sample loading is fast and easy. The stage is moved manually in the X and Y directions by turning two knobs on the door to the SEM chamber. It is not possible to adjust the height of the stage, and it is not possible to rotate and tilt samples. However, samples can be mounted on pinstubs with a fixed tilt angle.

In this SEM little effort is required to obtain decent SEM images. However, the tabletop SEM has a limited resolution and a limited number of settings you can optimize compared to the other SEMs at Nanolab. For inspection of samples with structures in the micrometer range it is very fast and easy to use. Unlike the other SEMs at Nanolab it is not necessary to take the SEM Tool Package Training course to be authorized to use the tabletop SEM.

The SEM can be operated in different pressure modes: Conductor, standard and charge-up reduction. By increasing the pressure in the chamber it is possible to inspect insulating samples, because the higher density of gas molecules will eliminate the charges at the cost of a slightly reduced resolution. Thus the charge-up reduction mode makes it possible to obtain SEM images of most samples including isolating samples without much sample preparation. If your sample charges a lot or you need higher resolution than what is possible in charge-up reduction mode, you also have the option to coat your sample with gold using Sputter Coater 03.

The user manual, control instruction, the user APV and contact information can be found in LabManager:

SEM Tabletop 1 info page in LabManager,

Performance information

Equipment performance

| Equipment | SEM Tabletop 1 (Hitachi TM3030 Plus ) | |

|---|---|---|

| Purpose | Imaging and measurement of |

|

| Location |

(in the North-East corner of the building, in the basement. Note that if you enter the building from the East, you enter directly into the basement.) | |

| Performance | Resolution |

The resolution is strongly dependent on the type of sample and the skills of the operator. |

| Instrument specifics | Detectors |

|

| Stage |

| |

| Electron source |

| |

| Operating pressures |

| |

| Substrates | Sample size |

|

| Allowed materials |

| |