Specific Process Knowledge/Lithography/Coaters/SprayCoater: Difference between revisions

No edit summary |

No edit summary |

||

| (25 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

{{cc-nanolab}} | |||

'''Feedback to this page''': '''[mailto:CustomerSupport@Nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Lithography/Coaters/SprayCoater click here]''' | |||

==Spray Coater== | ==Spray Coater== | ||

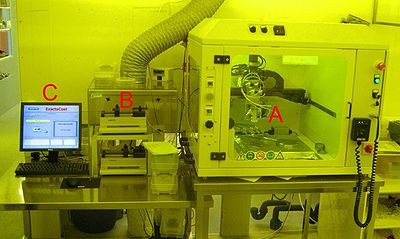

[[image:1042_spraycoater_overview.jpg|400x239px|right|thumb|Spray Coater in Cleanroom C-1]] | |||

The spray coater at DTU Nanolab is located in Cleanroom C-1. The machine is an ExactaCoat from Sono-tek which can be fitted with one of three different nozzles depending on the nature of the spray coating tasks at hand. The three different nozzles (Impact, AccuMist and Vortex) are optimized for different applications such as spray coating of large areas (e.g. entire wafers), smaller areas (e.g. wafer pieces or other small samples) or already structured samples that cannot be coated uniformly by spin coating. All nozzles use an ultrasonic tranducer for atomizing the solution to be spray coated. It is therefore a prerequisite that all components are compatible with this process. This is the case with most substances, although process parameters may need optimization to give satisfactory results. | |||

Practically any sample that will fit inside the spray coater can be processed. Spray patterns are easily programmed either using predefined spray patterns (1D line, 2D rectangles/circles/meanders/spirals) or custom 3D spray patterns. | |||

The spray | The spray coating process as well as major features of the three nozzles are described into more detail in the manual which can be found via the Equipment Info page in LabManager under the Documents sections. The manual can also be found by clicking [http://labmanager.dtu.dk/d4Show.php?id=2523&mach=293 this direct link]. | ||

'''Further information about the spray coater (manual, process log, technical information etc.) can be found in LabManger''': | |||

[http://labmanager.dtu.dk/function.php?module=Machine&view=view&mach=293 Spray coater in LabManager]''' | |||

== Process development== | |||

*[[/AZ4562|Spray coating using AZ4562]] | |||

*[[/TISpray|Spray coating using TI Spray]] | |||

==Equipment performance and process related parameters== | |||

{| border="2" cellspacing="0" cellpadding="2" | {| border="2" cellspacing="0" cellpadding="2" | ||

| Line 21: | Line 30: | ||

|style="background:LightGrey; color:black"| | |style="background:LightGrey; color:black"| | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*Spraying imprint | *Spraying imprint resists (primarily mr-NIL 6000E and mr-I 8000E) | ||

*Spraying photoresist | *Spraying photoresist (primarily AZ-4562) | ||

*Spraying of other solutions | *Spraying of other solutions | ||

|- | |- | ||

| Line 28: | Line 37: | ||

|style="background:LightGrey; color:black"|Substrate handling | |style="background:LightGrey; color:black"|Substrate handling | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* Can handle almost any sample size and shape | * Can handle almost any sample size and shape (although no automatic handling) | ||

|- | |- | ||

|style="background:LightGrey; color:black"|Permanent media | |style="background:LightGrey; color:black"|Permanent media | ||

| Line 41: | Line 50: | ||

|style="background:LightGrey; color:black"|Solution viscosity | |style="background:LightGrey; color:black"|Solution viscosity | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

* | *Should not exceed 20 cP | ||

|- | |- | ||

|style="background:LightGrey; color:black"|Chemical properties | |style="background:LightGrey; color:black"|Chemical properties | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*Must be non-toxic | *Must be non-toxic | ||

* | *Must be compatible with titanium | ||

*Resistant to ultrasonic | *Resistant to ultrasonic sonication | ||

|- | |- | ||

!style="background:silver; color:black" align="center" valign="center" rowspan="3"|Substrates | !style="background:silver; color:black" align="center" valign="center" rowspan="3"|Substrates | ||

|style="background:LightGrey; color:black"|Batch size | |style="background:LightGrey; color:black"|Batch size | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*Any sample(s) that fit inside machine | *Any sample(s) size and number that fit inside machine | ||

|- | |- | ||

| style="background:LightGrey; color:black"|Allowed materials | | style="background:LightGrey; color:black"|Allowed materials | ||

|style="background:WhiteSmoke; color:black"| | |style="background:WhiteSmoke; color:black"| | ||

*All chemicals to be spray coated must be approved specifically for spray coating | *'''All chemicals to be spray coated must be approved specifically for spray coating''' | ||

* | *Most non-toxic, non-particulate and non-crosslinking material likely to be approved | ||

*Suspensions challenging due to very low diameter tubing | |||

|- | |- | ||

|} | |} | ||

Latest revision as of 14:49, 10 May 2023

The contents on this page, including all images and pictures, was created by DTU Nanolab staff unless otherwise stated.

Feedback to this page: click here

Spray Coater

The spray coater at DTU Nanolab is located in Cleanroom C-1. The machine is an ExactaCoat from Sono-tek which can be fitted with one of three different nozzles depending on the nature of the spray coating tasks at hand. The three different nozzles (Impact, AccuMist and Vortex) are optimized for different applications such as spray coating of large areas (e.g. entire wafers), smaller areas (e.g. wafer pieces or other small samples) or already structured samples that cannot be coated uniformly by spin coating. All nozzles use an ultrasonic tranducer for atomizing the solution to be spray coated. It is therefore a prerequisite that all components are compatible with this process. This is the case with most substances, although process parameters may need optimization to give satisfactory results.

Practically any sample that will fit inside the spray coater can be processed. Spray patterns are easily programmed either using predefined spray patterns (1D line, 2D rectangles/circles/meanders/spirals) or custom 3D spray patterns.

The spray coating process as well as major features of the three nozzles are described into more detail in the manual which can be found via the Equipment Info page in LabManager under the Documents sections. The manual can also be found by clicking this direct link.

Further information about the spray coater (manual, process log, technical information etc.) can be found in LabManger:

Process development

| Equipment | Spray Coater | |

|---|---|---|

| Purpose |

| |

| Performance | Substrate handling |

|

| Permanent media |

| |

| Manual dispense option |

| |

| Process parameter range | Solution viscosity |

|

| Chemical properties |

| |

| Substrates | Batch size |

|

| Allowed materials |

| |