Specific Process Knowledge/Etch/ICP Metal Etcher/silicon oxide/By BGHE: Difference between revisions

| (35 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

{{CC-bghe1}} <br> | |||

<!-- cheched by bghe 2021-08-18--> | |||

I tried with two different gas regimes: CF4 and C4F8. I only made a few tests with CF4 since I got a very bad selectivity to the resist mask and I dicided to go for the C4F8 instead. | I (bghe@nanolab 2016) tried with two different gas regimes: CF4 and C4F8. I only made a few tests with CF4 since I got a very bad selectivity to the resist mask and I dicided to go for the C4F8 instead.<br> | ||

Zhibo Li @ Danchip has also tried (December 2016) with similar setting, see his results in this file: [[:File:Zhibo Li SiO2 ICP etch (dose205).docx]] | |||

==C4F8== | ==C4F8== | ||

{{CC-bghe2}} <br> | |||

I started out with a recipe developed by Peixiong called pxSiO2try9, look at his results [[Specific Process Knowledge/Etch/ICP Metal Etcher/silicon oxide/By Peixiong| here]] | I started out with a recipe developed by Peixiong called pxSiO2try9, look at his results [[Specific Process Knowledge/Etch/ICP Metal Etcher/silicon oxide/By Peixiong| here]] | ||

{| border="1" cellspacing="1" cellpadding="1" align="left" | {|style="width:1500px" border="1" cellspacing="1" cellpadding="1" align="left" | ||

! Parameter | ! Parameter | ||

! '''Mask material''' | ! '''Mask material''' | ||

| Line 18: | Line 20: | ||

! width="20"| '''T''' | ! width="20"| '''T''' | ||

! '''Process time''' | ! '''Process time''' | ||

! '''Comment''' | ! width="200"| '''Comment''' | ||

! width=" | ! width="200"|'''Results''' | ||

! '''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | ! width="200"|'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | ||

trench opening as a fraction of pitch | trench opening as a fraction of pitch | ||

! '''Profile angles''' | ! '''Profile angles''' | ||

| Line 42: | Line 44: | ||

|<!--'''T'''--> 0 | |<!--'''T'''--> 0 | ||

|<!--'''Process time'''--> 1:30min | |<!--'''Process time'''--> 1:30min | ||

|<!--'''Comment'''--> The layer in this case is 300nm Si3N4 | |width="200"|<!--'''Comment'''--> The layer in this case is 300nm Si3N4 | ||

|<!--'''Results'''--> | |width="200"|<!--'''Results'''--> | ||

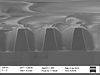

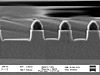

[[File:s008684_Si3N4_19.jpg|100px|frameless]] [[File:s008684_Si3N4_20.jpg|100px|frameless]] | [[File:s008684_Si3N4_19.jpg|100px|frameless]] [[File:s008684_Si3N4_20.jpg|100px|frameless]] | ||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | ||

| Line 62: | Line 64: | ||

? | ? | ||

|- | |- | ||

|-style="background:white; color:black" | |||

|s007785 | |||

|<!-- '''Mask material''' --> 880nm KRF | |||

|<!-- '''Barc etch''' -->pxbarcO2 25s | |||

|<!-- '''Coil power''' --> 800W | |||

|<!--'''Platen power'''--> 200W | |||

|<!--'''Pressure'''--> 2.5mTorr | |||

|<!--'''Flow rate C4F8'''--> 13sccm | |||

|<!--'''Flow rate H2'''--> 26sccm | |||

|<!--'''Flow rate Ar'''-->0 | |||

|<!--'''T'''--> 0 | |||

|<!--'''Process time'''--> 7 min | |||

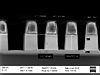

|width="200"|<!--'''Comment'''--> One of the good ones. the mask is well preserved | |||

|width="200"|<!--'''Results'''--> | |||

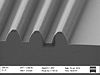

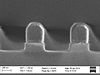

[[File:s007785_05.jpg|100px|frameless]] [[File:s007785_08.jpg|100px|frameless]] | |||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |||

trench opening as a fraction of pitch--> | |||

37% (1µm pitch)<br> | |||

48% (4µm pitch)<br> | |||

|<!--'''Profile angles'''--> | |||

83-86 | |||

|<!--'''Etch depth in SiO2'''--> | |||

>1000 nm | |||

|<!--'''Etch rate'''--> | |||

>143nm/mi | |||

|<!--'''Etch depth in resist'''--> | |||

250nm | |||

|<!--'''Selectivity (resist:SiO2)'''--> | |||

>1:4 | |||

|<!--'''Etch rate in Si'''--> | |||

? | |||

|- | |||

|- | |||

|-style="background:white; color:black" | |||

|s007679 | |||

|<!-- '''Mask material''' --> 880nm KRF | |||

|<!-- '''Barc etch''' -->barc etch CF 40s | |||

|<!-- '''Coil power''' --> 800W | |||

|<!--'''Platen power'''--> 200W | |||

|<!--'''Pressure'''--> 2.5mTorr | |||

|<!--'''Flow rate C4F8'''--> 13sccm | |||

|<!--'''Flow rate H2'''--> 26sccm | |||

|<!--'''Flow rate Ar'''-->0 | |||

|<!--'''T'''--> 0 | |||

|<!--'''Process time'''--> 8 min | |||

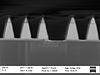

|width="200"|<!--'''Comment'''--> One of the good ones. the mask is well preserved, CF barc etch | |||

|width="200"|<!--'''Results'''--> | |||

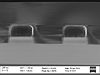

[[File: ICP metal s007679_01.jpg|100px|frameless]] [[File:ICP metal s007679_04.jpg|100px|frameless]] | |||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |||

trench opening as a fraction of pitch--> | |||

42% (1µm pitch)<br> | |||

48% (4µm pitch)<br> | |||

|<!--'''Profile angles'''--> | |||

83-89 | |||

|<!--'''Etch depth in SiO2'''--> | |||

>1074 nm | |||

|<!--'''Etch rate'''--> | |||

>134nm/min | |||

|<!--'''Etch depth in resist'''--> | |||

310nm | |||

|<!--'''Selectivity (resist:SiO2)'''--> | |||

>1:3.5 | |||

|<!--'''Etch rate in Si'''--> | |||

? | |||

|- | |||

|- | |||

|-style="background:white; color:black" | |||

|s007592 | |||

|<!-- '''Mask material''' --> 880nm KRF | |||

|<!-- '''Barc etch''' -->barc etch CF 40s | |||

|<!-- '''Coil power''' --> 1000W | |||

|<!--'''Platen power'''--> 200W | |||

|<!--'''Pressure'''--> 2.5mTorr | |||

|<!--'''Flow rate C4F8'''--> 10sccm | |||

|<!--'''Flow rate H2'''--> 28sccm | |||

|<!--'''Flow rate Ar'''-->0 | |||

|<!--'''T'''--> 0 | |||

|<!--'''Process time'''--> 5 min | |||

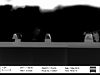

|width="200"|<!--'''Comment'''--> One of the good ones. the mask is well preserved, CF barc etch | |||

|width="200"|<!--'''Results'''--> | |||

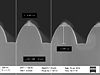

[[File: ICP metal s007592_21.jpg|100px|frameless]] [[File:ICP metal s007592_24.jpg|100px|frameless]] | |||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |||

trench opening as a fraction of pitch--> | |||

41% (1µm pitch)<br> | |||

47% (4µm pitch)<br> | |||

|<!--'''Profile angles'''--> | |||

86-87 | |||

|<!--'''Etch depth in SiO2'''--> | |||

727 nm (1µm) <br> | |||

864 nm (4µm) | |||

|<!--'''Etch rate'''--> | |||

145 nm/min (1µm pitch) <br> | |||

172 nm/min (4µm pitch | |||

|<!--'''Etch depth in resist'''--> | |||

170nm | |||

|<!--'''Selectivity (resist:SiO2)'''--> | |||

1:4.3 (1µm P)<br> | |||

1:5.1 [4µm P) | |||

|<!--'''Etch rate in Si'''--> | |||

? | |||

|- | |||

|- | |||

|-style="background:white; color:black" | |||

|s007593 | |||

|<!-- '''Mask material''' --> 880nm KRF | |||

|<!-- '''Barc etch''' -->barc etch CF 40s | |||

|<!-- '''Coil power''' --> 800W | |||

|<!--'''Platen power'''--> 100W | |||

|<!--'''Pressure'''--> 2.5mTorr | |||

|<!--'''Flow rate C4F8'''--> 10sccm | |||

|<!--'''Flow rate H2'''--> 28sccm | |||

|<!--'''Flow rate Ar'''-->0 | |||

|<!--'''T'''--> 0 | |||

|<!--'''Process time'''--> 8 min | |||

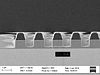

|width="200"|<!--'''Comment'''--> One of the good ones. the mask is well preserved, CF barc etch. The small pitch line are etched much slower that the higher pitch lines | |||

|width="200"|<!--'''Results'''--> | |||

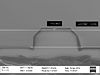

[[File: ICP metal s007593_25.jpg|100px|frameless]] [[File:ICP metal s007593_28.jpg|100px|frameless]] | |||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |||

trench opening as a fraction of pitch--> | |||

32% (1µm pitch)<br> | |||

45% (4µm pitch)<br> | |||

|<!--'''Profile angles'''--> | |||

85-86 | |||

|<!--'''Etch depth in SiO2'''--> | |||

501 nm (1µm) <br> | |||

881 nm (4µm) | |||

|<!--'''Etch rate'''--> | |||

63 nm/min (1µm pitch) <br> | |||

110 nm/min (4µm pitch | |||

|<!--'''Etch depth in resist'''--> | |||

100nm | |||

|<!--'''Selectivity (resist:SiO2)'''--> | |||

1:5.0 (1µm P)<br> | |||

1:8.8 [4µm P) | |||

|<!--'''Etch rate in Si'''--> | |||

? | |||

|- | |||

|- | |||

|s007467 (as 18) | |||

|<!-- '''Mask material''' --> 750nm KRF | |||

|<!-- '''Barc etch''' --> none | |||

|<!-- '''Coil power''' --> 1000W | |||

|<!--'''Platen power'''--> 150W | |||

|<!--'''Pressure'''--> 2.5mTorr | |||

|<!--'''Flow rate C4F8'''--> 8sccm | |||

|<!--'''Flow rate H2'''--> 30sccm | |||

|<!--'''Flow rate Ar'''-->0 | |||

|<!--'''T'''--> 0 | |||

|<!--'''Process time'''--> 10min | |||

|width="200"|<!--'''Comment'''--> | |||

|width="200"|<!--'''Results'''--> | |||

[[File:ICP metal s007467_07.jpg|100px|frameless]] [[File:ICP metal s007467_09.jpg|100px|frameless]] | |||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |||

trench opening as a fraction of pitch--> | |||

? (2µm pitch)<br> | |||

52% (average) (3µm pitch)<br> | |||

51% (average) (6µm pitch)<br> | |||

|<!--'''Profile angles'''--> | |||

77 (6µm p) | |||

|<!--'''Etch depth in SiO2'''--> | |||

1015 nm (2µm pitch)<br> | |||

1032 nm (3µm pitch)<br> | |||

1060 nm (6µm pitch)<br> | |||

|<!--'''Etch rate'''--> | |||

101.5 nm/min (2µm pitch)<br> | |||

103.2 nm/min (3µm pitch)<br> | |||

106.0 nm/min (6µm pitch)<br> | |||

|<!--'''Etch depth in resist'''--> | |||

210nm | |||

|<!--'''Selectivity (resist:SiO2)'''--> | |||

1:4.8 (2µm pitch)<br> | |||

1:4.9 (3µm pitch)<br> | |||

1:5.0 (6µm pitch)<br> | |||

|<!--'''Etch rate in Si'''--> | |||

|- | |||

|s007418 | |||

|<!-- '''Mask material''' --> 750nm KRF | |||

|<!-- '''Barc etch''' --> none | |||

|<!-- '''Coil power''' --> 1000W | |||

|<!--'''Platen power'''--> 150W | |||

|<!--'''Pressure'''--> 2.5mTorr | |||

|<!--'''Flow rate C4F8'''--> 8sccm | |||

|<!--'''Flow rate H2'''--> 30sccm | |||

|<!--'''Flow rate Ar'''-->0 | |||

|<!--'''T'''--> 0 | |||

|<!--'''Process time'''--> 5min | |||

|width="200"|<!--'''Comment'''--> | |||

|width="200"|<!--'''Results'''--> | |||

[[File:ICP metal s007418_09.jpg|100px|frameless]] [[File:ICP metal s007418_12.jpg|100px|frameless]] | |||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |||

trench opening as a fraction of pitch--> | |||

46.5% (2µm pitch)<br> | |||

49.0% (4µm pitch)<br> | |||

|<!--'''Profile angles'''--> | |||

87-88 (large structures) | |||

|<!--'''Etch depth in SiO2'''--> | |||

400 nm (6µm pitch)<br> | |||

|<!--'''Etch rate'''--> | |||

80 nm/min (6µm pitch)<br> | |||

|<!--'''Etch depth in resist'''--> | |||

200nm/76nm? | |||

|<!--'''Selectivity (resist:SiO2)'''--> | |||

1:2 (6µm pitch)<br> | |||

1:5? | |||

|<!--'''Etch rate in Si'''--> | |||

|- | |||

|s007565 (as 16) | |||

|<!-- '''Mask material''' --> 880nm KRF | |||

|<!-- '''Barc etch''' --> barc etch CF 40s | |||

|<!-- '''Coil power''' --> 800W | |||

|<!--'''Platen power'''--> 100W | |||

|<!--'''Pressure'''--> 2.5mTorr | |||

|<!--'''Flow rate C4F8'''--> 13sccm | |||

|<!--'''Flow rate H2'''--> 26sccm | |||

|<!--'''Flow rate Ar'''-->0 | |||

|<!--'''T'''--> 0 | |||

|<!--'''Process time'''--> 8min | |||

|width="200"|<!--'''Comment'''--> repeated s007416 and s007468 with a barc etch step. This improved the uniformity of the etch performance over different linewidth and improved the selectivity to the mask and the profile angle. After this I continued with barc etch. '''Nice''' | |||

|width="200"|<!--'''Results'''--> | |||

[[File:ICP metal s007565_02.jpg|100px|frameless]] [[File:ICP metal s007565_06.jpg|100px|frameless]] | |||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |||

trench opening as a fraction of pitch--> | |||

44.5% (2µm pitch)<br> | |||

46.8% (3µm pitch)<br> | |||

47.8% (4µm pitch) | |||

|<!--'''Profile angles'''--> | |||

87-88 | |||

|<!--'''Etch depth in SiO2'''--> | |||

779 nm (2µm pitch)<br> | |||

862 nm (3µm pitch)<br> | |||

854 nm (4µm pitch) | |||

|<!--'''Etch rate'''--> | |||

97.4 nm/min (2µm pitch)<br> | |||

107.8 nm/min (3µm pitch)<br> | |||

106.8 nm/min (4µm pitch) | |||

|<!--'''Etch depth in resist'''--> | |||

130nm | |||

|<!--'''Selectivity (resist:SiO2)'''--> | |||

1:6.0 (2µm pitch)<br> | |||

1:6.6 (3µm pitch)<br> | |||

1:6.6 (4µm pitch) | |||

|<!--'''Etch rate in Si'''--> | |||

|- | |||

|s007468 (as 16) | |||

|<!-- '''Mask material''' --> 750nm KRF | |||

|<!-- '''Barc etch''' --> none | |||

|<!-- '''Coil power''' --> 800W | |||

|<!--'''Platen power'''--> 100W | |||

|<!--'''Pressure'''--> 2.5mTorr | |||

|<!--'''Flow rate C4F8'''--> 13sccm | |||

|<!--'''Flow rate H2'''--> 26sccm | |||

|<!--'''Flow rate Ar'''-->0 | |||

|<!--'''T'''--> 0 | |||

|<!--'''Process time'''--> 10min | |||

|width="200"|<!--'''Comment'''--> Repeated s007416 with double time. | |||

|width="200"|<!--'''Results'''--> | |||

[[File:ICP metal s007468_12.jpg|100px|frameless]] [[File:ICP metal s007468_15.jpg|100px|frameless]] | |||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |||

trench opening as a fraction of pitch--> | |||

17.3% (1µm pitch)<br> | |||

33.5% (2µm pitch)<br> | |||

38.3% (3µm pitch)<br> | |||

41.4% (4µm pitch) | |||

|<!--'''Profile angles'''--> | |||

76-78 | |||

|<!--'''Etch depth in SiO2'''--> | |||

850 nm (1µm pitch)<br> | |||

1034 nm (2µm pitch)<br> | |||

1048 nm (3µm pitch)<br> | |||

1055 nm (4µm pitch) | |||

|<!--'''Etch rate'''--> | |||

85 nm/min (1µm pitch)<br> | |||

103.4 nm/min (2µm pitch)<br> | |||

104.8 nm/min (3µm pitch)<br> | |||

105.5 nm/min (4µm pitch) | |||

|<!--'''Etch depth in resist'''--> | |||

300nm | |||

|<!--'''Selectivity (resist:SiO2)'''--> | |||

1:2.8 (1µm pitch)<br> | |||

1:3.4 (2µm pitch)<br> | |||

1:3.5 (3µm pitch)<br> | |||

1:3.5 (4µm pitch) | |||

|<!--'''Etch rate in Si'''--> | |||

|- | |||

|s007416 | |||

|<!-- '''Mask material''' --> 750nm KRF | |||

|<!-- '''Barc etch''' --> none | |||

|<!-- '''Coil power''' --> 800W | |||

|<!--'''Platen power'''--> 100W | |||

|<!--'''Pressure'''--> 2.5mTorr | |||

|<!--'''Flow rate C4F8'''--> 13sccm | |||

|<!--'''Flow rate H2'''--> 26sccm | |||

|<!--'''Flow rate Ar'''-->0 | |||

|<!--'''T'''--> 0 | |||

|<!--'''Process time'''--> 5min | |||

|width="200"|<!--'''Comment'''--> From S007411 the platen power was decreased to avoid trenching. The etch rate went down and some variation in profile angle is seen from small opening to large opening. Started plasma on the 4th try | |||

|width="200"|<!--'''Results'''--> | |||

[[File:ICP metal s007416_05.jpg|100px|frameless]] [[File:ICP metal s007416_06.jpg|100px|frameless]] | |||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |||

trench opening as a fraction of pitch--> | |||

38.6% (2µm pitch)<br> | |||

45.4% (5µm pitch)<br> | |||

|<!--'''Profile angles'''--> | |||

77 (small structures) | |||

90 (large structures) | |||

|<!--'''Etch depth in SiO2'''--> | |||

346 nm (1.5µm pitch)<br> | |||

454 nm (5µm pitch)<br> | |||

|<!--'''Etch rate'''--> | |||

69 nm/min (1.5µm pitch)<br> | |||

91 nm/min (5µm pitch)<br> | |||

|<!--'''Etch depth in resist'''--> | |||

50nm | |||

|<!--'''Selectivity (resist:SiO2)'''--> | |||

1:7 (1.5µm pitch)<br> | |||

1:9 (5µm pitch)<br> | |||

|<!--'''Etch rate in Si'''--> | |||

|- | |||

|s007411 | |||

|<!-- '''Mask material''' --> 750nm KRF | |||

|<!-- '''Barc etch''' --> none | |||

|<!-- '''Coil power''' --> 800W | |||

|<!--'''Platen power'''--> 150W | |||

|<!--'''Pressure'''--> 2.5mTorr | |||

|<!--'''Flow rate C4F8'''--> 13sccm | |||

|<!--'''Flow rate H2'''--> 26sccm | |||

|<!--'''Flow rate Ar'''-->0 | |||

|<!--'''T'''--> 0 | |||

|<!--'''Process time'''--> 5min | |||

|width="200"|<!--'''Comment'''--> From s007409 the Gas flow ratio between C4F8 and H2 has been changed to more C4F8 and less H2. This increased the etch rate (more fluorine). Trenching is seen and tappered sidewall is seen indicating a more physical etch. | |||

|width="200"|<!--'''Results'''--> | |||

[[File:ICP metal s007411_01.jpg|100px|frameless]] [[File:ICP metal s007411_02.jpg|100px|frameless]] | |||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |||

trench opening as a fraction of pitch--> | |||

47.0% (1µm pitch)<br> | |||

44.6% (2µm pitch)<br> | |||

|<!--'''Profile angles'''--> | |||

83 | |||

|<!--'''Etch depth in SiO2'''--> | |||

708 nm<br> | |||

|<!--'''Etch rate'''--> | |||

142 nm/min | |||

|<!--'''Etch depth in resist'''--> | |||

294 nm | |||

|<!--'''Selectivity (resist:SiO2)'''--> | |||

1:2.4 <br> | |||

|<!--'''Etch rate in Si'''--> | |||

|- | |||

|s007419 | |||

|<!-- '''Mask material''' --> 750nm KRF | |||

|<!-- '''Barc etch''' --> none | |||

|<!-- '''Coil power''' --> 800W | |||

|<!--'''Platen power'''--> 200W | |||

|<!--'''Pressure'''--> 2.5mTorr | |||

|<!--'''Flow rate C4F8'''--> 8sccm | |||

|<!--'''Flow rate H2'''--> 30sccm | |||

|<!--'''Flow rate Ar'''-->0 | |||

|<!--'''T'''--> 0 | |||

|<!--'''Process time'''--> 5min | |||

|width="200"|<!--'''Comment'''--> Increased the platen power. The selectivity and profile looks good but the resist profile has been rounded more on the edge and this will effect the profile for a deeper etch. | |||

|width="200"|<!--'''Results'''--> | |||

[[File:ICP metal s007419_17.jpg|100px|frameless]] [[File:ICP metal s007419_21.jpg|100px|frameless]] | |||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |||

trench opening as a fraction of pitch--> | |||

46.6% (1µm pitch)<br> | |||

47.8% (2µm pitch)<br> | |||

48.4% (4µm pitch)<br> | |||

|<!--'''Profile angles'''--> | |||

86-90 | |||

|<!--'''Etch depth in SiO2'''--> | |||

270nm (1µm pitch)<br> | |||

400nm (2.5µm pitch)<br> | |||

|<!--'''Etch rate'''--> | |||

54 nm/min (1µm pitch)<br> | |||

80 nm/min (2.5µm pitch)<br> | |||

|<!--'''Etch depth in resist'''--> | |||

100nm | |||

|<!--'''Selectivity (resist:SiO2)'''--> | |||

1:4 (2.5µm pitch)<br> | |||

|<!--'''Etch rate in Si'''--> | |||

|- | |||

|s007410 | |||

|<!-- '''Mask material''' --> 750nm KRF | |||

|<!-- '''Barc etch''' --> none | |||

|<!-- '''Coil power''' --> 800W | |||

|<!--'''Platen power'''--> 75W | |||

|<!--'''Pressure'''--> 2.5mTorr | |||

|<!--'''Flow rate C4F8'''--> 8sccm | |||

|<!--'''Flow rate H2'''--> 30sccm | |||

|<!--'''Flow rate Ar'''-->0 | |||

|<!--'''T'''--> 0 | |||

|<!--'''Process time'''--> 7min | |||

|width="200"|<!--'''Comment'''--> Reduced the platen power.Effect: ARDE - less CD increase but more possitive tappered profile. | |||

|width="200"|<!--'''Results'''--> | |||

[[File:ICP metal s007410_05.jpg|100px|frameless]] [[File:ICP metal s007410_09.jpg|100px|frameless]] | |||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |||

trench opening as a fraction of pitch--> | |||

42.3% (2µm pitch)<br> | |||

47.0% (average) (3µm pitch)<br> | |||

|<!--'''Profile angles'''--> | |||

80-82 | |||

|<!--'''Etch depth in SiO2'''--> | |||

0 nm (1µm pitch)<br> | |||

270 nm (3µm pitch)<br> | |||

|<!--'''Etch rate'''--> | |||

0 nm/min (1µm pitch)<br> | |||

39nm/min (?µm pitch)<br> | |||

|<!--'''Etch depth in resist'''--> | |||

100nm | |||

|<!--'''Selectivity (resist:SiO2)'''--> | |||

1:0 (1µm pitch)<br> | |||

1:2.7 (2µm pitch)<br> | |||

|<!--'''Etch rate in Si'''--> | |||

|- | |||

|s006656 | |s006656 | ||

| Line 75: | Line 499: | ||

|<!--'''T'''--> 0 | |<!--'''T'''--> 0 | ||

|<!--'''Process time'''--> 10min | |<!--'''Process time'''--> 10min | ||

|<!--'''Comment'''--> Tried with C4F8/Ar instead of C4F8/H2 => much lower etch rate and bad selectivity to the resist. | |width="200"|<!--'''Comment'''--> Tried with C4F8/Ar instead of C4F8/H2 => much lower etch rate and bad selectivity to the resist. | ||

|<!--'''Results'''--> | |width="200"|<!--'''Results'''--> | ||

[[File:ICP metal s006656 no1.jpg|100px|frameless]] [[File:ICP metal s006656 no2.jpg|100px|frameless]] | [[File:ICP metal s006656 no1.jpg|100px|frameless]] [[File:ICP metal s006656 no2.jpg|100px|frameless]] | ||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | ||

| Line 106: | Line 530: | ||

|<!--'''T'''--> 0 | |<!--'''T'''--> 0 | ||

|<!--'''Process time'''--> 5min | |<!--'''Process time'''--> 5min | ||

|<!--'''Comment'''--> Repeated Pexiongs recipe without barc etch and only 5 min's runs. It probably takes about 1 min to get through the barc. If you count that in then the etch rate and relectivity to resist is almost the same as for the first run. Effect: CD increase | |width="200"|<!--'''Comment'''--> Repeated Pexiongs recipe without barc etch and only 5 min's runs. It probably takes about 1 min to get through the barc. If you count that in then the etch rate and relectivity to resist is almost the same as for the first run. Effect: CD increase | ||

|<!--'''Results'''--> | |width="200"|<!--'''Results'''--> | ||

[[File:ICP metal s007409_06.jpg|100px|frameless]] [[File:ICP metal s007409_07.jpg|100px|frameless]] | [[File:ICP metal s007409_06.jpg|100px|frameless]] [[File:ICP metal s007409_07.jpg|100px|frameless]] | ||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | ||

| Line 141: | Line 565: | ||

|<!--'''T'''--> 0 | |<!--'''T'''--> 0 | ||

|<!--'''Process time'''--> 10min | |<!--'''Process time'''--> 10min | ||

|<!--'''Comment'''--> From Peixiong | |width="200"|<!--'''Comment'''--> From Peixiong | ||

|<!--'''Results'''--> | |width="200"|<!--'''Results'''--> | ||

[[File:S0061066_n02.jpg|100px|frameless]] [[File:S006106_n04.jpg|100px|frameless]] | [[File:S0061066_n02.jpg|100px|frameless]] [[File:S006106_n04.jpg|100px|frameless]] | ||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | ||

Latest revision as of 09:27, 10 February 2023

This page is written by Berit Herstrøm @ DTU Nanolab (BGHE) if nothing else is stated

I (bghe@nanolab 2016) tried with two different gas regimes: CF4 and C4F8. I only made a few tests with CF4 since I got a very bad selectivity to the resist mask and I dicided to go for the C4F8 instead.

Zhibo Li @ Danchip has also tried (December 2016) with similar setting, see his results in this file: File:Zhibo Li SiO2 ICP etch (dose205).docx

C4F8

Unless otherwise stated, all content in this section was done by Berit Herstrøm, DTU Nanolab

I started out with a recipe developed by Peixiong called pxSiO2try9, look at his results here

| Parameter | Mask material | Barc etch | Coil power | Platen power | Pressure | Flow rate C4F8 | Flow rate H2 | Flow rate Ar | T | Process time | Comment | Results | CD change (mask 55% trench) after s007467 is it <50% after barc etch trench opening as a fraction of pitch |

Profile angles | Etch depth in SiO2 | Etch rate | Etch depth in resist | Selectivity (resist:SiO2) | Etch rate in Si |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| s008684 | 880nm KRF | barc etch CF 50s | 1000W | 200W | 2.5mTorr | 13sccm | 30sccm | 0 | 0 | 1:30min | The layer in this case is 300nm Si3N4 |

35% (1µm pitch) |

83-88 |

>300nm/min (Si3N4) |

240nm |

~1:2 (Si3N4) |

? | ||

| s007785 | 880nm KRF | pxbarcO2 25s | 800W | 200W | 2.5mTorr | 13sccm | 26sccm | 0 | 0 | 7 min | One of the good ones. the mask is well preserved |

37% (1µm pitch) |

83-86 |

>1000 nm |

>143nm/mi |

250nm |

>1:4 |

? | |

| s007679 | 880nm KRF | barc etch CF 40s | 800W | 200W | 2.5mTorr | 13sccm | 26sccm | 0 | 0 | 8 min | One of the good ones. the mask is well preserved, CF barc etch |

42% (1µm pitch) |

83-89 |

>1074 nm |

>134nm/min |

310nm |

>1:3.5 |

? | |

| s007592 | 880nm KRF | barc etch CF 40s | 1000W | 200W | 2.5mTorr | 10sccm | 28sccm | 0 | 0 | 5 min | One of the good ones. the mask is well preserved, CF barc etch |

41% (1µm pitch) |

86-87 |

727 nm (1µm) |

145 nm/min (1µm pitch) |

170nm |

1:4.3 (1µm P) |

? | |

| s007593 | 880nm KRF | barc etch CF 40s | 800W | 100W | 2.5mTorr | 10sccm | 28sccm | 0 | 0 | 8 min | One of the good ones. the mask is well preserved, CF barc etch. The small pitch line are etched much slower that the higher pitch lines |

32% (1µm pitch) |

85-86 |

501 nm (1µm) |

63 nm/min (1µm pitch) |

100nm |

1:5.0 (1µm P) |

? | |

| s007467 (as 18) | 750nm KRF | none | 1000W | 150W | 2.5mTorr | 8sccm | 30sccm | 0 | 0 | 10min |

? (2µm pitch) |

77 (6µm p) |

1015 nm (2µm pitch) |

101.5 nm/min (2µm pitch) |

210nm |

1:4.8 (2µm pitch) |

|||

| s007418 | 750nm KRF | none | 1000W | 150W | 2.5mTorr | 8sccm | 30sccm | 0 | 0 | 5min |

46.5% (2µm pitch) |

87-88 (large structures) |

400 nm (6µm pitch) |

80 nm/min (6µm pitch) |

200nm/76nm? |

1:2 (6µm pitch) |

| ||

| s007565 (as 16) | 880nm KRF | barc etch CF 40s | 800W | 100W | 2.5mTorr | 13sccm | 26sccm | 0 | 0 | 8min | repeated s007416 and s007468 with a barc etch step. This improved the uniformity of the etch performance over different linewidth and improved the selectivity to the mask and the profile angle. After this I continued with barc etch. Nice |

44.5% (2µm pitch) |

87-88 |

779 nm (2µm pitch) |

97.4 nm/min (2µm pitch) |

130nm |

1:6.0 (2µm pitch) |

||

| s007468 (as 16) | 750nm KRF | none | 800W | 100W | 2.5mTorr | 13sccm | 26sccm | 0 | 0 | 10min | Repeated s007416 with double time. |

17.3% (1µm pitch) |

76-78 |

850 nm (1µm pitch) |

85 nm/min (1µm pitch) |

300nm |

1:2.8 (1µm pitch) |

||

| s007416 | 750nm KRF | none | 800W | 100W | 2.5mTorr | 13sccm | 26sccm | 0 | 0 | 5min | From S007411 the platen power was decreased to avoid trenching. The etch rate went down and some variation in profile angle is seen from small opening to large opening. Started plasma on the 4th try |

38.6% (2µm pitch) |

77 (small structures) 90 (large structures) |

346 nm (1.5µm pitch) |

69 nm/min (1.5µm pitch) |

50nm |

1:7 (1.5µm pitch) |

| |

| s007411 | 750nm KRF | none | 800W | 150W | 2.5mTorr | 13sccm | 26sccm | 0 | 0 | 5min | From s007409 the Gas flow ratio between C4F8 and H2 has been changed to more C4F8 and less H2. This increased the etch rate (more fluorine). Trenching is seen and tappered sidewall is seen indicating a more physical etch. |

47.0% (1µm pitch) |

83 |

708 nm |

142 nm/min |

294 nm |

1:2.4 |

||

| s007419 | 750nm KRF | none | 800W | 200W | 2.5mTorr | 8sccm | 30sccm | 0 | 0 | 5min | Increased the platen power. The selectivity and profile looks good but the resist profile has been rounded more on the edge and this will effect the profile for a deeper etch. |

46.6% (1µm pitch) |

86-90 |

270nm (1µm pitch) |

54 nm/min (1µm pitch) |

100nm |

1:4 (2.5µm pitch) |

||

| s007410 | 750nm KRF | none | 800W | 75W | 2.5mTorr | 8sccm | 30sccm | 0 | 0 | 7min | Reduced the platen power.Effect: ARDE - less CD increase but more possitive tappered profile. |

42.3% (2µm pitch) |

80-82 |

0 nm (1µm pitch) |

0 nm/min (1µm pitch) |

100nm |

1:0 (1µm pitch) |

||

| s006656 | 750nm KRF | none | 1000W | 150W | 2.5mTorr | 15sccm | 0sccm | 30sccm | 0 | 10min | Tried with C4F8/Ar instead of C4F8/H2 => much lower etch rate and bad selectivity to the resist. |

358 nm |

35.8 nm/min (2µm pitch) |

526nm |

1:0:68 |

||||

| s007409 | 750nm KRF | none | 800W | 150W | 2.5mTorr | 8sccm | 30sccm | 0 | 0 | 5min | Repeated Pexiongs recipe without barc etch and only 5 min's runs. It probably takes about 1 min to get through the barc. If you count that in then the etch rate and relectivity to resist is almost the same as for the first run. Effect: CD increase |

47.4% (1µm pitch) |

86-89 |

280 nm (1µm pitch) |

56 nm/min (1µm pitch) |

160nm |

1:1.8 (1µm pitch) |

||

| s006106 | 750nm KRF | Barc etch O2 75s | 800W | 150W | 2.5mTorr | 8sccm | 30sccm | 0 | 0 | 10min | From Peixiong |

60% |

79 |

1053 nm (center) |

105 nm/min |

280nm |

1:3:75 (2µm pitch) |

CF4

I stopped trying with CF4 because I got bad selectivty to the resist and decided to focus on the recipe with C4F8 instead.