Specific Process Knowledge/Characterization/Profiler/Optical Profiler (Sensofar) acceptance test: Difference between revisions

| (13 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

'''Feedback to this page''': '''[mailto:labadviser@nanolab.dtu.dk?Subject=Feed%20back%20from%20page%20http://labadviser.nanolab.dtu.dk/index.php/Specific_Process_Knowledge/Characterization/Profiler/Optical_Profiler_(Sensofar)_acceptance_test click here]''' | |||

=<span style="color:#FF0000"> This optical profiler has been decommissioned and replaced by the S Neox system </span> = | |||

=Results from the Optical Profiler (Sensofar) acceptance test= | =Results from the Optical Profiler (Sensofar) acceptance test= | ||

The acceptance test was performed in January 2012 by ST Instruments and Sensofar together with | The acceptance test was performed in January 2012 by ST Instruments and Sensofar together with | ||

Pernille V. Larsen @ | Pernille V. Larsen@ DTU nanolab and Berit G. Herstrøm @ DTU nanolab. | ||

==This Table shows an overview of the acceptance tests== | ==This Table shows an overview of the acceptance tests== | ||

| Line 117: | Line 121: | ||

*Objective: Interferometric 50x DI | *Objective: Interferometric 50x DI | ||

*Z scan: VSI | *Z scan: VSI | ||

*Light | *Light source: increased gain and contrast | ||

==Results of acceptance test no. 4== | ==Results of acceptance test no. 4== | ||

| Line 124: | Line 128: | ||

Measurement: Depth of pattern | Measurement: Depth of pattern | ||

Standard profiler measurement: | Standard profiler measurement:335 nm | ||

Acceptance criteria:Depth within ±1% from a standard profiler measurement (331.65nm-338.35nm) and repeatability (3 successive measurements) within 0.1% | Acceptance criteria:Depth within ±1% from a standard profiler measurement (331.65nm-338.35nm) and repeatability (3 successive measurements) within 0.1% | ||

| Line 152: | Line 156: | ||

| align="center" style="background:#f0f0f0;"|'''''' | | align="center" style="background:#f0f0f0;"|'''''' | ||

| align="center" style="background:#f0f0f0;"|'''Measured depth [nm]''' | | align="center" style="background:#f0f0f0;"|'''Measured depth [nm]''' | ||

| align="center" style="background:#f0f0f0;"|'''Repeated 20170925 with cover off''' | |||

| align="center" style="background:#f0f0f0;"|'''Repeated 20180816 after repair''' | |||

|- | |- | ||

| 1||337.5 | | 1||337.5||347.9||341.1 | ||

|- | |- | ||

| 2||336.5 | | 2||336.5||333.9||340.4 | ||

|- | |- | ||

| 3||334.7 | | 3||334.7||341.5||337.2 | ||

|- | |- | ||

| 4||335.5 | | 4||335.5||343.2||330.8 | ||

|- | |- | ||

| 5||339.2 | | 5||339.2||347.7||339.0 | ||

|- | |- | ||

| 6||337.2 | | 6||337.2||345.4||340.0 | ||

|- | |- | ||

| 7||334.2 | | 7||334.2||341.8||338.8 | ||

|- | |- | ||

| 8||335.5 | | 8||335.5||337.9||339.8 | ||

|- | |- | ||

| 9||341.1 | | 9||341.1||342.1||334.6 | ||

|- | |- | ||

| 10||344.4 | | 10||344.4||335.9||336.4 | ||

|- | |- | ||

|Average depth|| | |Average depth||337.58||341.73||337.82 | ||

|- | |- | ||

|Repeatability||3% (the bad repeatability was accepted due to the high noise level in the room) | |Repeatability||3.0% (the bad repeatability was accepted due to the high noise level in the room)||4.1%||3.0% | ||

|} | |} | ||

| Line 243: | Line 249: | ||

'''Settings:''' | '''Settings:''' | ||

Two different setting were tried out, the second was the most | Two different setting were tried out, the second was the most successful: | ||

Setting no. 1: | Setting no. 1: | ||

| Line 295: | Line 301: | ||

{| border="1" cellspacing="1" cellpadding="2" | {| border="1" cellspacing="1" cellpadding="2" | ||

! | ! | ||

[[image:Sensofar_A9_SEM.jpg| | [[image:Sensofar_A9_SEM.jpg|200x200px|thumb|center|SEM profile image of structure]] | ||

|} | |} | ||

| Line 329: | Line 335: | ||

Measurement:Film thickness measurement of transparent thin film | Measurement:Film thickness measurement of transparent thin film | ||

Acceptance criteria:SiO2 thickness 28±1 nm | Acceptance criteria: SiO2 thickness 28±1 nm | ||

| Line 344: | Line 350: | ||

==Results of acceptance test no. 11== | ==Results of acceptance test no. 11== | ||

Sample:120 nm nitride on 110 nm oxide on a silicon substrate | Sample: 120 nm nitride on 110 nm oxide on a silicon substrate | ||

Measurement:Measurements of multiple stacks | Measurement: Measurements of multiple stacks | ||

Acceptance criteria: Within ±2% on each layer from an ellipsometer measurement (SiO2: 112nm, Si3N4: 139nm) | Acceptance criteria: Within ±2% on each layer from an ellipsometer measurement (SiO2: 112nm, Si3N4: 139nm) | ||

| Line 363: | Line 369: | ||

Sample: Si with 1.4 µm patterned AZ-resist on 50µm pillars | Sample: Si with 1.4 µm patterned AZ-resist on 50µm pillars | ||

Measurement:Film thickness measurements of transparent films on small structure | Measurement: Film thickness measurements of transparent films on small structure | ||

Acceptance criteria:Within ±1% from a standard profiler measurement. | Acceptance criteria: Within ±1% from a standard profiler measurement. | ||

| Line 386: | Line 392: | ||

Acceptance criteria: Repeatability within 0.2% | Acceptance criteria: Repeatability within 0.2% | ||

Note: Because the surface roughness of the sample was very low and the noise/vibration level too high we could not obtain the specified | Note: Because the surface roughness of the sample was very low and the noise/vibration level too high we could not obtain the specified repeatability. | ||

| Line 392: | Line 398: | ||

'''Result''' | '''Result''' | ||

*The surface roughness (Ra) was 0.5nm | *The surface roughness (Ra) was 0.5nm | ||

*The | *The repeatability over 10 measurements was 34% | ||

*The maximum deviation in roughness was 0.2nm | *The maximum deviation in roughness was 0.2nm | ||

Latest revision as of 11:35, 3 February 2023

Feedback to this page: click here

This optical profiler has been decommissioned and replaced by the S Neox system

Results from the Optical Profiler (Sensofar) acceptance test

The acceptance test was performed in January 2012 by ST Instruments and Sensofar together with Pernille V. Larsen@ DTU nanolab and Berit G. Herstrøm @ DTU nanolab.

This Table shows an overview of the acceptance tests

| ' | Title | Sample description / measurement | Acceptance criteria |

| 1 | Patterned flat sample of silicon | Sample material: Patterned silicon substrate Trench depth with aspect ratio 1:10 on a 10 µm wide trench |

Depth 100±2 µm |

| 2 | Patterned flat sample of silicon. | Sample material: Patterned silicon substrate Trench depth with aspect ratio 1:11 on a 8 µm wide trench |

Depth 91±2 µm |

| 3 | Patterned flat sample of silicon | Sample material: Patterned silicon substrate Trench depth with aspect ratio 1:13 on a 6.4 µm wide trench |

Depth 85±2 µm |

| 4 | Patterned flat sample of glass | 3D profile of pattern etched down in a quartz sample. Pattern size 20 µm x 20 µm, depth 500 nm |

Depth within ±1% from a standard profiler measurement and repeatability (3 successive measurements) within 0.1% |

| 5 | Flat sample of silicon with thick patterned oxide | Step height of patterned thick (10 µm) oxide on top of a silicon wafer. 7 µm deep pattern, trench width 6 µm |

Step height must be within ±3% of a SEM profile measurement. |

| 6 | Flat sample of silicon with thick layer of patterned polymer | Sample material: SU8 on silicon. Pillar heights of 69 µm with 25 µm between pillar edges |

Height 69±2 µm |

| 7 | Free standing structure | Measure bow due to stress of a membrane. Membrane material: Si(2 µm)/SiO2(~1 µm)/Au(50 nm) Membrane size: honey comb structure approximately 150 µm in diameter Bow < 500 nm |

Membrane bow repeatability of 5 successive measurement within 2% |

| 8 | Stitching of large area | Stitching 4 mm x 4 mm on same sample as in 7. The area consists of many closed packed honey comb formed membranes. | Membrane bow must the same as on 7 within 2% |

| 9 | Narrow trenches and holes | Sample material: Patterned silicon substrate 2.5 µm wide trench in silicon with a depth of 20 µm |

Depth 20±2 µm |

| 10 | Film thickness measurement of transparent thin film | Transparent thin film thickness of 28 nm SiO2 on Si | SiO2 thickness 28±1 nm |

| 11 | Measurements of multiple stacks | 120 nm nitride on 110 nm oxide on a silicon substrate | Within ±2% on each layer from an ellipsometer measurement. |

| 12 | Film thickness measurements of transparent films on small structure | Sample material: Si with 1.5 µm patterned AZ-resist Measure thickness of AZ-resist on pillars of 50 µm in diameter |

Within ±1% from a standard profiler measurement. |

| 13 | Roughness repeatability | Sample material: Si wafer with poly-silicon layer 3 successive measurements of the roughness |

Repeatability within 0.2% |

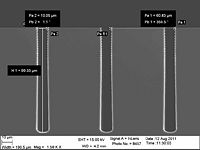

Results of acceptance test no. 1, 2 and 3

Sample material: Patterned silicon substrate

Measurement: Trench depth with aspect ratio 1:10, 1:11 and 1:13 on a 10µm, 8mm and 6.4µm wide trenches respectively

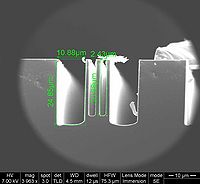

Acceptance criteria: Depth 100±2 µm, 91±2µm and 85±2µm. The SEM profile images of the three trenches are shown here:

|

|

|

|---|

Results

Test no. 1 was done in two ways:

- With confocal objective EPI 100x-N: See the results here

- With Interferometric objective 50X DI: See the results here

Test no. 2 was done using: confocal objective EPI 100x-N: See the results here

Test no. 3 was done using: confocal objective EPI 100x-N: See the results here

Settings for methode no. 1 for test no. 1, 2 and 3: confocal

Recipe: Trench

- Operation mode: trench

- + Raw smoothing confocal

- + fine shift

- Objective: EPI 100X-N

- Z scan

- Dual - bottom up

- top: 8µm

- Gap: 91µm (<- choose the trench depth)

- Bottom: 8µm

- Speed factor: 1x

- + Linear stage

- Dual - bottom up

- Threshold: 0.0%

- Light source

- Levels: 2

- 900 -> 60 (might need to be set a little different)

- Gain: default

- Levels: 2

Setting for methode no. 2 for test no. 1: interferometric

We do not have a recipe for that but we used:

- Objective: Interferometric 50x DI

- Z scan: VSI

- Light source: increased gain and contrast

Results of acceptance test no. 4

Sample material: Patterned flat sample of glass

Measurement: Depth of pattern

Standard profiler measurement:335 nm

Acceptance criteria:Depth within ±1% from a standard profiler measurement (331.65nm-338.35nm) and repeatability (3 successive measurements) within 0.1%

System settings:

Objective: DI 50x-N

VSI z scan: 10µm

Treshold: 1%

Average 4 images (to reduce noise)

Results

It was repeated 10 Time.

The first measurement is shown here

This table show the depth value for the 10 measurements

| ' | Measured depth [nm] | Repeated 20170925 with cover off | Repeated 20180816 after repair |

| 1 | 337.5 | 347.9 | 341.1 |

| 2 | 336.5 | 333.9 | 340.4 |

| 3 | 334.7 | 341.5 | 337.2 |

| 4 | 335.5 | 343.2 | 330.8 |

| 5 | 339.2 | 347.7 | 339.0 |

| 6 | 337.2 | 345.4 | 340.0 |

| 7 | 334.2 | 341.8 | 338.8 |

| 8 | 335.5 | 337.9 | 339.8 |

| 9 | 341.1 | 342.1 | 334.6 |

| 10 | 344.4 | 335.9 | 336.4 |

| Average depth | 337.58 | 341.73 | 337.82 |

| Repeatability | 3.0% (the bad repeatability was accepted due to the high noise level in the room) | 4.1% | 3.0% |

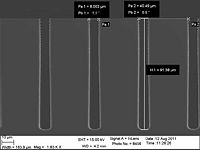

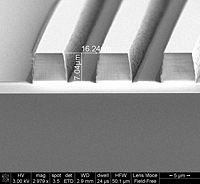

Results of acceptance test no. 5

Sample: Flat sample of silicon with thick patterned oxide (APOX).

Measurement: Step height of patterned thick (10 µm) oxide on top of a silicon wafer. The pattern is aprox. 7µm thick.

Acceptance criteria: Step height must be within ±3% of a SEM profile measurement. See the SEM profile here:

|

|---|

Settings:

- Recipe: Acceptance nr. 5 SMR

- Mode: default

- Objective: 50x-DI

- VSI Z scan 18.0µm

- Threshold 2%

- Note: Scan only in the APOX (not in the Si) or else the system will get confused.

See the result here:

Results of acceptance test no. 6

Sample: Flat sample of silicon with thick layer of patterned SU8.

Measure: step height.

Acceptance criteria: Height 69±2 µm

Settings:

- Recipe: Acceptance nr. 6 SMR

- Mode: application Acceptance 6

- Raw smoothing confocal

- Coarse shift single samle

- Reject multiple reflections

- Objective: Confocal EPI 20x-N

- Z scan range: 104µm

- Threshold: 2.0%

See the result here:

Results of acceptance test no. 7

Sample: Free standing structure. Membrane material: Si(2 µm)/SiO2(~1 µm)/Au(50 nm). Membrane size: honey comb structure approximately 150 µm in diameter

Measure: Measure bow due to stress of a membrane.

Acceptance criteria: Membrane bow repeatability of 5 successive measurement within 2%

The sample was not as we suspected. There was almost no bow. The membrane looked broken and it did not really make any sense to measure the bow.

Settings: Two different setting were tried out, the second was the most successful:

Setting no. 1:

- Objective: DI 50x-N

- PSI

- Threshold 2%

Setting no. 2:

- Objective: DI 50x-N

- Z scan: VSI 10µm

- Threshold: 1.0%

Result

The measurement we did are shown here:

Results of acceptance test no. 8

Measurement: Stitching 4 mm x 4 mm on same sample as in 7.

Sample: The area consists of many closed packed honey comb formed membranes

Acceptance criteria: Membrane bow must the same as on 7 within 2%

Settings:

- Extended topography

- Objective: DI 20x-N

- Z scan: VSI: 40µm

- Threshold: 1.0%

Result:

We made a stitched image of the hole membrane and repeated it two times. It looked much the same but as for test 7 it was hard to do any measurements on it. See the images and profiles in the result file:

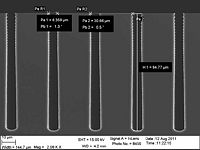

Results of acceptance test no. 9

Sample: Patterned silicon substrate.

Measurement: Narrow trench depth

Acceptance criteria: 20±2µm, see the SEM images here:

|

|---|

Setting

Recipe: Narrow trench

- Operation mode: narrow trench

- Coarse shift single sampling

- Objective: EPI 100X-N

- Z scan:

- Dual - bottom up

- top: 4µm

- Gap: 20µm (the trench depth)

- Bottom: 4µm

- Dual - bottom up

- Speed factor: 1x

- Threshold: 0.0%

- Light source:

- Levels: 2

- 176 -> 30 (might need to be set a little different)

- Gain: default

Result

Results of acceptance test no. 10

Sample: Transparent thin film thickness of 28 nm SiO2 on Si

Measurement:Film thickness measurement of transparent thin film

Acceptance criteria: SiO2 thickness 28±1 nm

Settings

- Objective: EPI 20x-N

- Model: SiO2 thermal

Result

The result was 28.7nm

Results of acceptance test no. 11

Sample: 120 nm nitride on 110 nm oxide on a silicon substrate

Measurement: Measurements of multiple stacks

Acceptance criteria: Within ±2% on each layer from an ellipsometer measurement (SiO2: 112nm, Si3N4: 139nm)

Settings Model layers use:

- SiO2_(therm)

- Si3N4

Result

- SiO2: 113.1nm

- Si3N4: 136.9nm

Results of acceptance test no. 12

Sample: Si with 1.4 µm patterned AZ-resist on 50µm pillars

Measurement: Film thickness measurements of transparent films on small structure

Acceptance criteria: Within ±1% from a standard profiler measurement.

Settings

Used Models -> Others -> Cauchy

Options -> Roughness -> change amplitude fitting

Result

Within limits

Results of acceptance test no. 13

Sample: Si wafer with poly-silicon layer

Measurement: Roughness repeatability, 3 successive measurements of the roughness

Acceptance criteria: Repeatability within 0.2%

Note: Because the surface roughness of the sample was very low and the noise/vibration level too high we could not obtain the specified repeatability.

Result

- The surface roughness (Ra) was 0.5nm

- The repeatability over 10 measurements was 34%

- The maximum deviation in roughness was 0.2nm

Se the number in the file below: