Specific Process Knowledge/Thin film deposition/Deposition of Tungsten/Evaporation of W in Temescal: Difference between revisions

Created page with "=Deposition of W in Temescal= During the e-beam deposition of Tungsten, extremely bright light and heat are generated! Lower density film than expected due to porosity. Consider using sputtering instead. Power 33W, stable rate, tooling 86%. Measured thickness 20 nm (XRR). <b>Wait for base pressure 3 10-7Torr before start.</b> {| border="2" cellspacing="2" cellpadding="2" colspan="3" |bgcolor="#98FB98" |'''Deposition of Tungsten. Dep. rate: 0.5Å/s, Thickness sp.:..." |

No edit summary |

||

| Line 3: | Line 3: | ||

During the e-beam deposition of Tungsten, extremely bright light and heat are generated! Lower density film than expected due to porosity. Consider using sputtering instead. | During the e-beam deposition of Tungsten, extremely bright light and heat are generated! Lower density film than expected due to porosity. Consider using sputtering instead. | ||

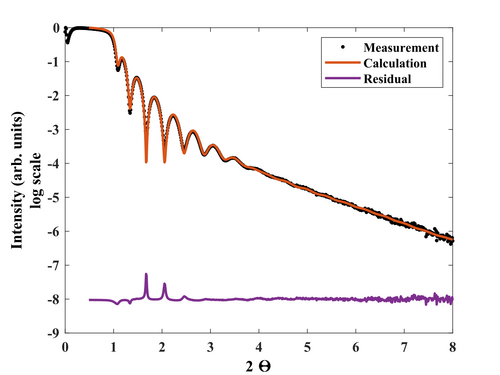

Power 33W, stable rate, tooling 86%. Measured thickness 20 nm (XRR). | Power 33W, stable rate, tooling 86%. Measured thickness 20 nm ([[Specific Process Knowledge/Characterization/XRD/XRD_SmartLab|XRR]]). | ||

<b>Wait for base pressure 3 10-7Torr before start.</b> | <b>Wait for base pressure 3 10-7Torr before start.</b> | ||

| Line 77: | Line 77: | ||

<gallery caption="XRR analysis of e-beam deposited Ta thin film." widths="500px" heights="500px" perrow="1"> | <gallery caption="XRR analysis of e-beam deposited Ta thin film." widths="500px" heights="500px" perrow="1"> | ||

image:eves_20220225_W_Temescal.png| X-ray reflectivity. Measurement and Fit. Tooling 86%. <b>Seems that this deposition suffered from a high oxidation level. (low fitted density of the main Ta layer) or poures formation</b> | image:eves_20220225_W_Temescal.png| [[Specific Process Knowledge/Characterization/XRD/XRD_SmartLab|X-ray reflectivity]]. Measurement and Fit. Tooling 86%. <b>Seems that this deposition suffered from a high oxidation level. (low fitted density of the main Ta layer) or poures formation</b> | ||

</gallery> | </gallery> | ||

Revision as of 16:11, 2 January 2023

Deposition of W in Temescal

During the e-beam deposition of Tungsten, extremely bright light and heat are generated! Lower density film than expected due to porosity. Consider using sputtering instead.

Power 33W, stable rate, tooling 86%. Measured thickness 20 nm (XRR).

Wait for base pressure 3 10-7Torr before start.

| Deposition of Tungsten. Dep. rate: 0.5Å/s, Thickness sp.: 20nm | |||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||

- XRR analysis of e-beam deposited Ta thin film.

-

X-ray reflectivity. Measurement and Fit. Tooling 86%. Seems that this deposition suffered from a high oxidation level. (low fitted density of the main Ta layer) or poures formation