Specific Process Knowledge/Etch/ICP Metal Etcher/silicon/isotropic/isoslow1: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

<!--Checked for updates on 11/2-2019 - ok/jmli --> | <!--Checked for updates on 11/2-2019 - ok/jmli --> | ||

<!--Checked for updates on 15/10-2021 - ok/jmli --> | |||

{| border="2" cellpadding="0" cellspacing="0" style="text-align:center;" | {| border="2" cellpadding="0" cellspacing="0" style="text-align:center;" | ||

|+ '''Process runs''' | |+ '''Process runs''' | ||

Latest revision as of 12:12, 15 October 2021

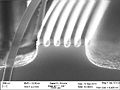

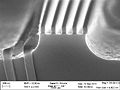

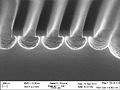

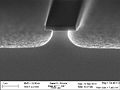

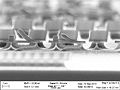

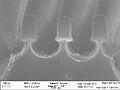

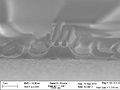

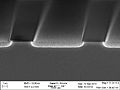

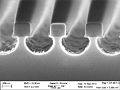

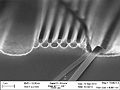

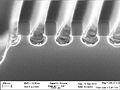

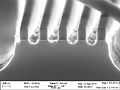

| Date | Substrate Information | Process Information | SEM Images | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Wafer info | Mask | Material/ Exposed area | Tool / Operator | Conditioning | Recipe | Wafer ID | Comments | ||

| 9/9-2014 | 6" First DUV box wafer | standard stepper mask (50 nm barc + 320 nm krf) | Si / 50%+ | ICP Metal Etch / jmli | 2*30 sec barc etch using 'slow etch with carrier' | danchip/jmlli/Si/isotropice/isoslow1 , 2:00 minutes | S005292 | ||