Specific Process Knowledge/Back-end processing/Polymer Injection Molder/Robot: Difference between revisions

| (33 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

== Robot sample pickup == | == Robot sample pickup == | ||

Once the sample has been ejected from the mold it is ready for pick-up by the robot. Once the pick-up process works without major problems it is not necessary to make adjustments. In some cases however, it may be desirable to make adjustments: | |||

The | *The robot sometimes misses a sample | ||

*The mold opening stroke or the ejector advanced position was changed | |||

*You want to change the way the samples are placed on the conveyor belt | |||

<br> | |||

'''''Be extremely careful when making changes to robot settings! Make sure you know the XYZ coordinate system of the machine before making adjustments (look inside the machine for axes references)! Make small, incremental adjustments (~1 millimeter) rather than large changes in positions to make sure you do not damage the robot or the mold! Ask DTU Nanolab staff if you are in doubt about anything. Keep the speed at 60% or below (speeds in the depositing area should not exceed 20%).''' | |||

'' | |||

<br><br> | |||

For safety reasons many of the parameters described below can only be changed when the machine is in manual mode. This is to avoid accidentally sending the robot on a collision course during production. The button in the bottom left corner of the screen is a toggle switch that changes the entire left column of buttons between injection molding parameters and robot settings. Press it once to change to robot setting icons and press it again to go back to injection molding parameter icons. When the robot icons are selected the 'Take-off' screen can be selected (third button from the top): | |||

[[File:08_robot.png|600px|thumb|left| | [[File:08_robot.png|600px|thumb|left|The Take-off screen contains parameters for robot positions and speeds relevant for sample removal.]] | ||

<br> | |||

*'''Position before opening:''' This is the home position of the robot (i.e. the waiting position of the robot while it is not working). It is rarely necessary to change this position. | |||

*If you change the 'Position before opening' then remember to press the Home button on the front panel afterwards to move the robot to the new home position. Otherwise you will get a 'Robot not in home position' error when switching to automatic mode. | |||

<br> | |||

*'''Moving-in positions 1 and 2:''' Two intermediate positions between the home position and the take-off (sample pickup) position. It is usually not necessary to change them. To improve reliability of the pick-up it is however recommended that: | |||

*The Y coordinate of 'Moving-in position 2' is identical to the Y coordinate of 'Take-off position' | |||

*The Z coordinate of 'Moving-in position 2' is identical to the Z coordinate of 'Take-off position' | |||

<br> | |||

*'''Take-off position XYZ''': This is the position in which the sample is picked up by the robot. Usually this is the only position that needs to be adjusted if you changed mold opening stroke, ejector pin advanced position or if the robot has problems picking up the sample. | |||

<br> | |||

*'''Moving-out positions 1 and 2''': Scroll down to see these settings. After sample pick-up the robot movement is also defined by two intermediate positions before the robot goes to the deposit position (placing sample on the conveyor belt). For simplicity the following settings are recommended: | |||

*'Move-out position 1' is set to the same position as 'Move-in position 2' | |||

*'Move-out position 2' is set to the same position as 'Move-in position 1' | |||

This ensures that the robot moves out the same way it moved in. | |||

<br><br><br><br><br><br> | |||

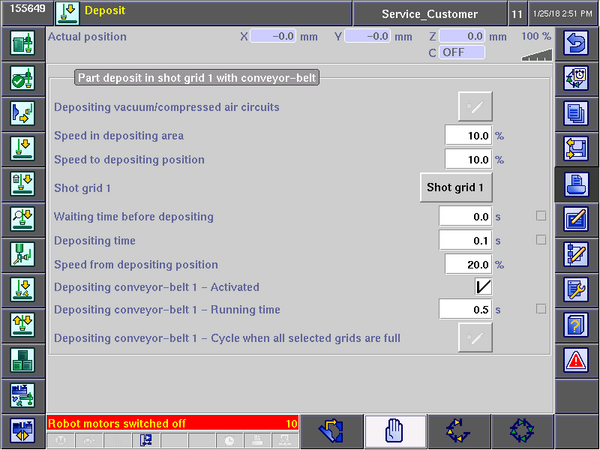

It is also possible to change how the samples are placed on the conveyor belt. Please note: Only 4 samples will fit per row on the conveyor belt! It looks like there's space enough for 5, but unfortunately there's not enough room for the robot to move that far out. The settings for depositing samples are found on the ''''Deposit'''' screen (fourth button from the top): | |||

[[File:10-deposit.png|600px|thumb|left|The Deposit screen contains setting for how the conveyor belt moves.]] | |||

<br><br><br><br><br> | |||

*'''Speed in/to/from depositing area:''' It is highly recommended to keep this speed around 10% - 20% | |||

<br> | |||

*'''Shot grid 1:''' This setting defines how samples are placed and stacked on the conveyor belt (see next section below) | |||

<br> | |||

*'''Depositing conveyor-belt 1 - Running time:''' This running time defines how far the belt moves between each row of samples on the belt. Unfortunately it is not possible to define a distance directly but only the running time. In general a running time of 0,5 - 0,6 sec results in a suitable distance between sample rows. If you want samples to move all the way out of the machine (but still not drop off the belt) a time around 8,5 sec is suitable. This is very handy when optimizing an injection molding process, where one often wants to inspect each sample immediately after production without having to manually move out the conveyor belt to get to the sample or opening the door in the back, which would cause an emergency stop of the machine. | |||

<br><br><br><br><br><br><br><br><br><br> | |||

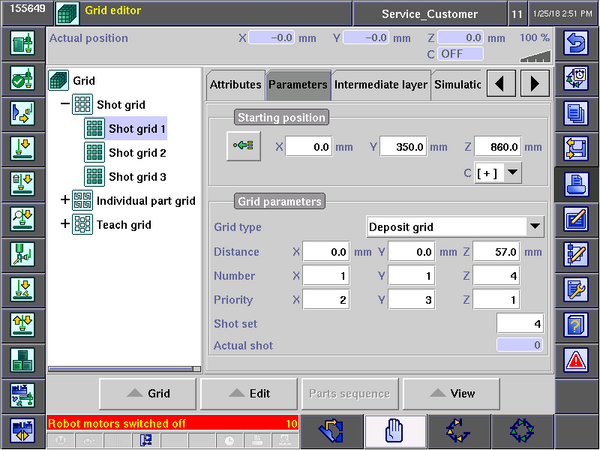

Pressing the ''''Shot grid 1'''' button on the '''Deposit''' screen shown above takes you to the 'Grid editor' screen. Here it is possible to define how samples are placed and stacked on the conveyor belt by selecting the 'Parameters' tab: | |||

[[File:11-grid.png|600px|thumb|left|The 'Grid editor' screen contains settings for how samples are placed on the conveyor belt.]] | |||

<br><br> | <br><br> | ||

Under 'Grid parameters' the settings for placing and stacking samples can be set: | |||

<br> | <br> | ||

*''' | *'''Distance:''' At DTU Nanolab it is customary to place samples next to each other on the belt (i.e. along the Z-axis). The space between each sample is thus defined by the Z value (here 57,0 mm). | ||

*'''Number:''' This setting defines how many samples are stacked/placed next to each other. A maximum of 4 samples side by side will fit on the belt and therefore all programs are usually left with Z = 4. While doing process development it can be advantageous to change this to Z = 1. This means only 1 sample is placed per row (and if the belt running time is also adjusted as described above, each individual sample can be transported out of the machine so it's easy to pick up for immediate inspection). It is also possible to stack samples on top of each other and in other directions by modifying the X and Y values, but '''please do NOT do this without contacting an equipment responsible from DTU Nanolab first. Therefore: For the 'Number' parameter please leave both X and Y at one unless you have a special agreement.'''. | |||

*'''Priority:''' This setting will define in which order samples are stacked along the three axes. The Z-axis should always be set as first priority (1), unless you have a special agreement with DTU Nanolab. | |||

Latest revision as of 12:27, 7 August 2020

Robot sample pickup

Once the sample has been ejected from the mold it is ready for pick-up by the robot. Once the pick-up process works without major problems it is not necessary to make adjustments. In some cases however, it may be desirable to make adjustments:

- The robot sometimes misses a sample

- The mold opening stroke or the ejector advanced position was changed

- You want to change the way the samples are placed on the conveyor belt

Be extremely careful when making changes to robot settings! Make sure you know the XYZ coordinate system of the machine before making adjustments (look inside the machine for axes references)! Make small, incremental adjustments (~1 millimeter) rather than large changes in positions to make sure you do not damage the robot or the mold! Ask DTU Nanolab staff if you are in doubt about anything. Keep the speed at 60% or below (speeds in the depositing area should not exceed 20%).

For safety reasons many of the parameters described below can only be changed when the machine is in manual mode. This is to avoid accidentally sending the robot on a collision course during production. The button in the bottom left corner of the screen is a toggle switch that changes the entire left column of buttons between injection molding parameters and robot settings. Press it once to change to robot setting icons and press it again to go back to injection molding parameter icons. When the robot icons are selected the 'Take-off' screen can be selected (third button from the top):

- Position before opening: This is the home position of the robot (i.e. the waiting position of the robot while it is not working). It is rarely necessary to change this position.

- If you change the 'Position before opening' then remember to press the Home button on the front panel afterwards to move the robot to the new home position. Otherwise you will get a 'Robot not in home position' error when switching to automatic mode.

- Moving-in positions 1 and 2: Two intermediate positions between the home position and the take-off (sample pickup) position. It is usually not necessary to change them. To improve reliability of the pick-up it is however recommended that:

- The Y coordinate of 'Moving-in position 2' is identical to the Y coordinate of 'Take-off position'

- The Z coordinate of 'Moving-in position 2' is identical to the Z coordinate of 'Take-off position'

- Take-off position XYZ: This is the position in which the sample is picked up by the robot. Usually this is the only position that needs to be adjusted if you changed mold opening stroke, ejector pin advanced position or if the robot has problems picking up the sample.

- Moving-out positions 1 and 2: Scroll down to see these settings. After sample pick-up the robot movement is also defined by two intermediate positions before the robot goes to the deposit position (placing sample on the conveyor belt). For simplicity the following settings are recommended:

- 'Move-out position 1' is set to the same position as 'Move-in position 2'

- 'Move-out position 2' is set to the same position as 'Move-in position 1'

This ensures that the robot moves out the same way it moved in.

It is also possible to change how the samples are placed on the conveyor belt. Please note: Only 4 samples will fit per row on the conveyor belt! It looks like there's space enough for 5, but unfortunately there's not enough room for the robot to move that far out. The settings for depositing samples are found on the 'Deposit' screen (fourth button from the top):

- Speed in/to/from depositing area: It is highly recommended to keep this speed around 10% - 20%

- Shot grid 1: This setting defines how samples are placed and stacked on the conveyor belt (see next section below)

- Depositing conveyor-belt 1 - Running time: This running time defines how far the belt moves between each row of samples on the belt. Unfortunately it is not possible to define a distance directly but only the running time. In general a running time of 0,5 - 0,6 sec results in a suitable distance between sample rows. If you want samples to move all the way out of the machine (but still not drop off the belt) a time around 8,5 sec is suitable. This is very handy when optimizing an injection molding process, where one often wants to inspect each sample immediately after production without having to manually move out the conveyor belt to get to the sample or opening the door in the back, which would cause an emergency stop of the machine.

Pressing the 'Shot grid 1' button on the Deposit screen shown above takes you to the 'Grid editor' screen. Here it is possible to define how samples are placed and stacked on the conveyor belt by selecting the 'Parameters' tab:

Under 'Grid parameters' the settings for placing and stacking samples can be set:

- Distance: At DTU Nanolab it is customary to place samples next to each other on the belt (i.e. along the Z-axis). The space between each sample is thus defined by the Z value (here 57,0 mm).

- Number: This setting defines how many samples are stacked/placed next to each other. A maximum of 4 samples side by side will fit on the belt and therefore all programs are usually left with Z = 4. While doing process development it can be advantageous to change this to Z = 1. This means only 1 sample is placed per row (and if the belt running time is also adjusted as described above, each individual sample can be transported out of the machine so it's easy to pick up for immediate inspection). It is also possible to stack samples on top of each other and in other directions by modifying the X and Y values, but please do NOT do this without contacting an equipment responsible from DTU Nanolab first. Therefore: For the 'Number' parameter please leave both X and Y at one unless you have a special agreement..

- Priority: This setting will define in which order samples are stacked along the three axes. The Z-axis should always be set as first priority (1), unless you have a special agreement with DTU Nanolab.