Specific Process Knowledge/Thin film deposition/ALD Picosun R200/ZnO deposition using ALD: Difference between revisions

Jump to navigation

Jump to search

| Line 14: | Line 14: | ||

|- | |- | ||

| | | | ||

! | !DEZ<sup>*</sup> | ||

!DEZ | |||

!H<sub>2</sub>O | |||

!H<sub>2</sub>O | !H<sub>2</sub>O | ||

|- | |- | ||

!Nitrogen flow | !Nitrogen flow | ||

|150 sccm | |||

|150 sccm | |150 sccm | ||

|200 sccm | |||

|200 sccm | |200 sccm | ||

|- | |- | ||

!Pulse time | !Pulse time | ||

|0.1 s | |||

|0.1 s | |||

|0.1 s | |0.1 s | ||

|0.1 s | |0.1 s | ||

|- | |- | ||

!Purge time | !Purge time | ||

| | |0.5 s | ||

| | |20.0 s | ||

|0.5 s | |||

|20.0 s | |||

|- | |- | ||

|} | |} | ||

<strong>DEZ</strong> is diethylzinc (Zn(CH<sub>2</sub>CH<sub>3</sub>)<sub>2</sub> or ZnEt<sub>2</sub>) | |||

<br clear="all" /> | <br clear="all" /> | ||

===ZnO deposition rates and uniformity=== | |||

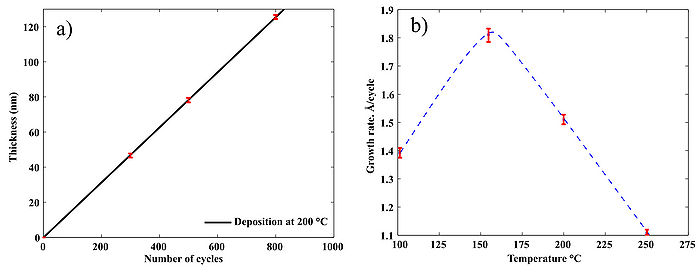

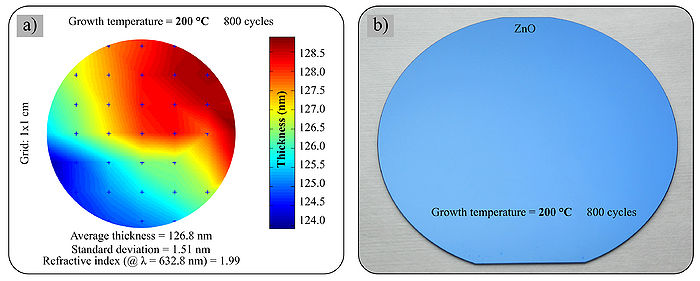

The deposition rate for ZnO depends on the temperature, see the ALD-window graph below. The uniformity, thickness, refractive index has been obtained using [[Specific_Process_Knowledge/Characterization/Optical_characterization#Ellipsometer|Ellipsometer VASE]]. | |||

<gallery caption="" widths=" | <gallery caption="" widths="700px" heights="300px" perrow="2"> | ||

image: | image:ALD_growth_rate_ZnO.jpg|Figure 1. a) Linear growth (~0.15 nm/cycles) @ 200 <sup>o</sup>C. b) ALD-window for ZnO deposition. | ||

image:ALD_SE_ZnO.jpg|Figure 2. a) Typical uniformity profile across 100mm Si wafer based on 49 mesurement points. b) Photography of the prepared wafer. | |||

image: | |||

</gallery> | </gallery> | ||

Revision as of 10:58, 20 March 2017

The ALD window for deposition of zinc oxide (ZnO) ranges from 100 oC to 250 oC. Several investigation techniques has been implemented for ZnO characterization. Additionally, more information on ZnO can be found on a page about Al-doped ZnO (AZO)

All results shown on this page have been obtained using the "ZnOT" recipe on new Si(100) wafers with native oxide:

ZnO standard recipe

Recipe: ZnOT

Maximum deposition thickness: 100 nm

Temperature: 100 oC - 250 oC

| DEZ* | DEZ | H2O | H2O | |

|---|---|---|---|---|

| Nitrogen flow | 150 sccm | 150 sccm | 200 sccm | 200 sccm |

| Pulse time | 0.1 s | 0.1 s | 0.1 s | 0.1 s |

| Purge time | 0.5 s | 20.0 s | 0.5 s | 20.0 s |

DEZ is diethylzinc (Zn(CH2CH3)2 or ZnEt2)

ZnO deposition rates and uniformity

The deposition rate for ZnO depends on the temperature, see the ALD-window graph below. The uniformity, thickness, refractive index has been obtained using Ellipsometer VASE.

Evgeniy Shkondin, DTU Danchip, 2014-2016.