Specific Process Knowledge/Etch/ICP Metal Etcher/silicon oxide/By BGHE: Difference between revisions

(→C4F8) |

(→C4F8) |

||

| Line 62: | Line 62: | ||

? | ? | ||

|- | |- | ||

|- | |||

|s007410 | |||

|<!-- '''Mask material''' --> 750nm KRF | |||

|<!-- '''Barc etch''' --> none | |||

|<!-- '''Coil power''' --> 800W | |||

|<!--'''Platen power'''--> 75W | |||

|<!--'''Pressure'''--> 2.5mTorr | |||

|<!--'''Flow rate C4F8'''--> 8sccm | |||

|<!--'''Flow rate H2'''--> 30sccm | |||

|<!--'''Flow rate Ar'''-->0 | |||

|<!--'''T'''--> 0 | |||

|<!--'''Process time'''--> 7min | |||

|<!--'''Comment'''--> ARDE - little CD increase | |||

|<!--'''Results'''--> | |||

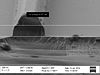

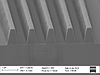

[[File:ICP metal s007410_05.jpg|100px|frameless]] [[File:ICP metal s007410_09.jpg|100px|frameless]] | |||

|<!--'''CD change (mask 55% trench) after s007467 is it <50% after barc etch'''<br> | |||

trench opening as a fraction of pitch--> | |||

42.3% (2µm pitch)<br> | |||

47.0% (average) (3µm pitch)<br> | |||

|<!--'''Profile angles'''--> | |||

80-82 | |||

|<!--'''Etch depth in SiO2'''--> | |||

0 nm (1µm pitch)<br> | |||

270 nm (3µm pitch)<br> | |||

|<!--'''Etch rate'''--> | |||

0 nm/min (1µm pitch)<br> | |||

39nm/min (?µm pitch)<br> | |||

|<!--'''Etch depth in resist'''--> | |||

100nm | |||

|<!--'''Selectivity (resist:SiO2)'''--> | |||

1:0 (1µm pitch)<br> | |||

1:2.7 (2µm pitch)<br> | |||

|<!--'''Etch rate in Si'''--> | |||

|- | |||

|s006656 | |s006656 | ||

Revision as of 11:45, 2 June 2016

THIS PAGE IS UNDER CONSTRUCTION

I tried with two different gas regimes: CF4 and C4F8. I only made a few tests with CF4 since I got a very bad selectivity to the resist mask and I dicided to go for the C4F8 instead.

C4F8

I started out with a recipe developed by Peixiong called pxSiO2try9, look at his results here

| Parameter | Mask material | Barc etch | Coil power | Platen power | Pressure | Flow rate C4F8 | Flow rate H2 | Flow rate Ar | T | Process time | Comment | Results | CD change (mask 55% trench) after s007467 is it <50% after barc etch trench opening as a fraction of pitch |

Profile angles | Etch depth in SiO2 | Etch rate | Etch depth in resist | Selectivity (resist:SiO2) | Etch rate in Si |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| s008684 | 880nm KRF | barc etch CF 50s | 1000W | 200W | 2.5mTorr | 13sccm | 30sccm | 0 | 0 | 1:30min | The layer in this case is 300nm Si3N4 |

35% (1µm pitch) |

83-88 |

>300nm/min (Si3N4) |

240nm |

~1:2 (Si3N4) |

? | ||

| s007410 | 750nm KRF | none | 800W | 75W | 2.5mTorr | 8sccm | 30sccm | 0 | 0 | 7min | ARDE - little CD increase |

42.3% (2µm pitch) |

80-82 |

0 nm (1µm pitch) |

0 nm/min (1µm pitch) |

100nm |

1:0 (1µm pitch) |

||

| s006656 | 750nm KRF | none | 1000W | 150W | 2.5mTorr | 15sccm | 0sccm | 30sccm | 0 | 10min | Tried with C4F8/Ar instead of C4F8/H2 => much lower etch rate and bad selectivity to the resist. |

358 nm |

35.8 nm/min (2µm pitch) |

526nm |

1:0:68 |

||||

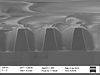

| s007409 | 750nm KRF | none | 800W | 150W | 2.5mTorr | 8sccm | 30sccm | 0 | 0 | 5min | Repeated Pexiongs recipe without barc etch and only 5 min's runs. It probably takes about 1 min to get through the barc. If you count that in then the etch rate and relectivity to resist is almost the same as for the first run. Effect: CD increase |

47.4% (1µm pitch) |

86-89 |

280 nm (1µm pitch) |

56 nm/min (1µm pitch) |

160nm |

1:1.8 (1µm pitch) |

||

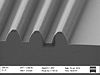

| s006106 | 750nm KRF | Barc etch O2 75s | 800W | 150W | 2.5mTorr | 8sccm | 30sccm | 0 | 0 | 10min | From Peixiong |

60% |

79 |

1053 nm (center) |

105 nm/min |

280nm |

1:3:75 (2µm pitch) |

CF4

I stopped trying with CF4 because I got bad selectivty to the resist and decided to focus on the recipe with C4F8 instead.

| Parameter/Wafer ID | s006687 | s006701 | s007258 | s007350 | s007352 |

|---|---|---|---|---|---|

| Mask material | 750nm KRF | 750nm KRF | 750nm KRF | 750 nm KRF | 750nm KRF |

| Barc etch | none | none | none | none | none |

| Coil power | 800W | 800W | 800w | 800w | 800w |

| Platen power | 100W | 100W | 100w | 60W | 30w |

| Pressure | 4mTorr | 4mTorr | 4mTorr | 4mTorr | 4mTorr |

| Flow rate CF4 | 20sccm | 25sccm | 30sccm | 30sccm | 30sccm |

| Flow rate H2 | 20sccm | 15sccm | 10sccm | 10sccm | 10sccm |

| T | 0 | 0 | 0 | 0 | 0 |

| Process time | 10min | 10min | 2min30 | 2min30 | 3min30 |

| Comment | Little resist left, Trenching | A little trenching | very little trenching in large lines - anti trenching in small lines | ||

| Results | |||||

| Etch depth in SiO2 | 374nm | 505nm | 578nm | 336nm | 235nm |

| Etch rate | 37.4nm/min | 50.5nm/min | 231nm/min | 134.4nm/min | 88nm/min |

| Etch depth in resist | 345nm | 633nm | 700nm | 405nm | 308nm |

| Selectivity (resist:SiO2) | 1:1.1 | 1:0.80 | 1:0.83 | 1:0.83 | 1:0.76 |