Specific Process Knowledge/Lithography/EBeamLithography: Difference between revisions

| Line 229: | Line 229: | ||

= Proximity Error Correction = | = Proximity Error Correction = | ||

[[Image:beamer5.jpg| | [[Image:beamer5.jpg|frame|180x180px|left]] | ||

<span style="font-size: 90%; text-align: right;">[[Specific_Process_Knowledge/Lithography/EBeamLithography#top|top of this page]]</span> | <span style="font-size: 90%; text-align: right;">[[Specific_Process_Knowledge/Lithography/EBeamLithography#top|top of this page]]</span> | ||

Revision as of 15:42, 8 August 2013

Feedback to this page: click here

The JEOL JBX-9500 electron beam lithography system is a spot electron beam type lithography system designed for writing patterns with dimensions from nanometers to sub-micrometers. The minimum electron beam is around 12 nm, the maximum writitng field without stitching is 1 mm x 1 mm.

The machine is located in a class 10 cleanroom (E-2) with tight temperature and moisture control. The room must only be entered when the machines or equipment inside the room is intended to be used.

Performance of the e-beam writer

| Purpose | pattern an electron sensitive resist | Mainly for pattering structures with minimum feature size between 20 nm - 1 µm |

|---|---|---|

| Performance | Resolution |

|

| Maximum writing area without stitching |

| |

| Process parameter range | E-beam voltage |

|

| Scanning speed |

| |

| Min. electron beam size |

| |

| Min. step size |

| |

| Beam current range |

| |

| Dose range |

| |

| Samples | Batch size |

Wafer cassettes:

|

| Substrate material allowed |

|

Getting started

To request a training session or a time-slot for the e-beam, contact the e-beam team via this link: e-beam@danchip.dtu.dk'

You need 3-4 training sessions before being allowed to use the e-beam writer. You can get training in loading and unloading samples into a cassette, to optically pre-align the samples, to calibrate the writer, to perform 2nd alignment and start exposure. For safety reasons, the costumer is however not allowed to load or unload cassettes to or from the e-beam writer.

Before you request for a training, it is crucial to have your pattern ready in either tdb-format or GDSII format. Also, check your pattern in e.g. CleWin before requesting. In order to reach the files from the computers inside the cleanroom, it is recommended to either dropbox them or send them per email to yourself.

It is also recommended to gather as much knowledge about your e-beam run from your colleagues, i.e. which e-beam current, aperture and dose to use, which shot pitch (e.g. SHOT A,10). In order to get an overview of what an e-beam process requires, it is recommended to a assist a fully trained colleague of yours when she or he e-beam writes. Furthermore, please read the e-beam manual for more information on which parameters to use.

There are 3 manuals for the e-beam writer:

- A user manual describing the standard procedure when e-beam writing

- A jdf-, and sdf-file manual describing how to prepare sdf-, and jdf-files (found under 'Technical Documents')

- A BEAMER manual describing how to convert your pattern file (GDSII-format) to v30-format (found under 'Technical Documents')

On the L-drive, a logbook for the e-beam writer can be found. Sheet 1 gives you an overview of which condition files (currents and apertures) have been in use recently by which user on which type of resist. On sheet 2 in this logbook you can find a writing time estimation program; please use this prior to requesting e-beam sessions. If in doubt how to use it, contact the e-beam team at [1].

E-beam resists and Process Flows

| Resist | Polarity | Manufacturer | Comments | Technical reports | Spinner | Developer | Rinse | Remover | Process flows (in docx-format) |

| ZEP520A | Positive | ZEON | Standard positive resist | ZEP520A.pdf | SSE, Manual Spinner 1 (Laurell), III-V Spinner | ZED-N50/Hexyl Acetate,n-amyl acetate, oxylene. JJAP-51-06FC05.pdf, JVB001037.pdf | IPA | acetone/1165 | Process_Flow_ZEP.docx

|

| ZEP7000 | Positive | ZEON | Low dose to clear. Used for trilayer (PEC-free) resist-stack. Please contact [Lithography] for information. | ZEP7000.pdf | Manual Spinner 1 (Laurell), III-V Spinner | ZED-N50/Hexyl Acetate,n-amyl acetate, oxylene. JJAP-51-06FC05.pdf, JVB001037.pdf | IPA | acetone/1165 | Trilayer stack: Process_Flow_Trilayer_Ebeam_Resist.docx |

| PMMA | Positive | We have various types of PMMA in the cleanroom, none are provided by DTU Danchip. Please contact [Lithography] for information. | Manual Spinner 1 (Laurell), III-V Spinner | MIBK:IPA (1:3), IPA:H2O | IPA | acetone/1165/Pirahna | |||

| MMA (AR-P 617.05) | Positive | AllResist | Approved, not tested yet. Used for trilayer (PEC-free) resist-stack or double-layer lift-off resist stack. Please contact [Lithography] for information. | AR_P617.pdf | Manual Spinner 1 (Laurell), III-V Spinner | AR600-55, MIBK:IPA | acetone/1165 | Trilayer stack: Process_Flow_Trilayer_Ebeam_Resist.docx

| |

| CSAR | Positive | AllResist | Approved, not tested yet. Should work similar to ZEP520A. Please contact [Lithography] for information. | CSAR_62_and_process_chemicals.pdf | Manual Spinner 1 (Laurell), III-V Spinner | X AR 600-54/6, MIBK:IPA | H2O | Process_Flow_CSAR.docx | |

| HSQ (XR-1541) | Negative | DOW Corning | III-V Spinner | TMAH, AZ400K:H2O | H2O |

| |||

| ma-N 2403 | Negative | Micro Resist | III-V Spinner | Ma-D333, TMAH, MIF726 | H2O | acteone/O2 plasma | |||

| AR-N 7520 | Negative | AllResist | Both e-beam, DUV and UV-sensitive resist. Currently being tested, contact [Peixiong Shi] for information. | AR-N7500-7520.pdf | Manual Spinner 1 (Laurell), III-V Spinner |

|

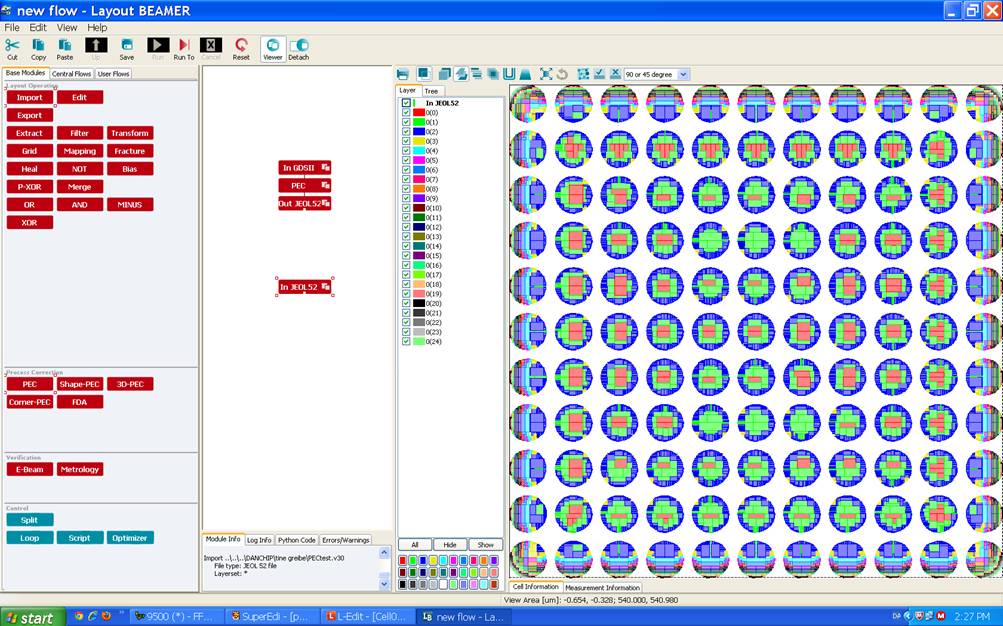

Proximity Error Correction

Even though the electron beam diameter is below 5 nm, the feature and pitch resolution in resist are limited by the forward and backward scattering of the electrons. The forward scattering depends on the electron acceleration voltage, the resist material and thickness. The backward scattering depends on the electron acceleration voltage and the substrate material [2], [3].

As the travel distance of backscattered electrons is fairly large, e-beam patterned structures will be influenced by adjacent e-beam patterned structures, i.e. a proximity effect. These proximity effects can be avoided either by simulating a proximity error correction (PEC) in BEAMER or by using the right stack of e-beam resist.

Proximity Error Correction (PEC) in BEAMER

BEAMER is endowed with a software that corrects for proximity errors in the e-beam exposure. You can ready more about this function in the BEAMER manual in LabManager under Technical Documents here and in the BEAMER presentation here BEAMERPresentation.pdf.

The proximity error correction require a forward and a backward range parameter, alfa and beta, and a ratio of backscattered energy to the forward scattered energy, eta. As alfa depends on the electron acceleration voltage, which is constant at 100kV, alfa is in BEAMER fixed to 0.007. Help to find beta and eta can be found here.

Alternatively, a point-spread function can be used in BEAMER to calculate the optimised dose-variation.

Trilayer resist stack

As an alternative to PEC, a trilayer reists stack with a thin layer of thermally evaporated Ge can be used [4]. This reists stack has not yet been tested at DTU Danchip. A process flow for this procedure can be found here Process_Flow_Trilayer_Ebeam_Resist.docx, but please contact Lithography before use.

Charging of non-conductive substrates

All substrates are grounded to the cassette when proper loaded. In a non-conducting substrate, the accumulation of charges in the substrates will however destroy the e-beam patterning. To avoid this, a charge dissipating layer is added on top of the e-beam resist; this will provide a conducting layer for the electrons to escape, while high-energy electrons will pass through the layer to expose the resist.

If you wish to investigate the charge dissipation using other methods than belwo, please contact Lithography.

Al coating

At DTU Danchip, we recommend to use a thin (20 nm) layer of thermally evaporated Aluminum on top of the e-beam resist. Preferably, the thickness of Al and the e-beam dose should be optimised to the features you wish to e-beam pattern, e.g. [5]. The 20 nm Al seems as a good starting point wherefrom dose and development can be optimised to reach the resolution and feature size required.

The process flow for a standard ZEP520 procedure with Al on top can be found here Process_Flow_ZEP_with_Al.docx.

ESPACER

We have ESPACER in stock and approved for use in the cleanroom but have not yet had the chance to investigate the material. You can find a guideline for a process flow here: Process_Flow_ZEP_ESPACER.docx. Technical information of EPSCAER can be found here: Espacer_300_Technical_Info.pdf, Espacer_catalog.pdf.

Please contact Lithography if you wish to test this material.