Specific Process Knowledge/Thin film deposition/Furnace LPCVD PolySilicon/Boron doped poly-Si and a-Si

Feedback to this page: click here

Unless otherwise stated, this page is written by DTU Nanolab internal

Boron-doped amorphous silicon by using 4" LPCVD polysilicon furnace (B4)

Result from Thomas Pedersen, DTU Nanotech (now DTU Nanolab), September 2015

Process parameters

Pressure: 250 mtorr

Temperature: 580 °C

Silane (SiH4) flow: Constant at 80 sccm

Diborane (B2H6) flow: Varied from 3 sccm to 40 sccm

Anneal: No annealing afterwards

Test wafer position: Center of the boat

Results

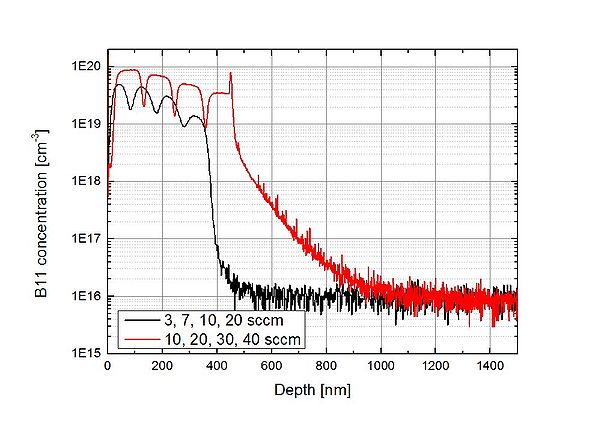

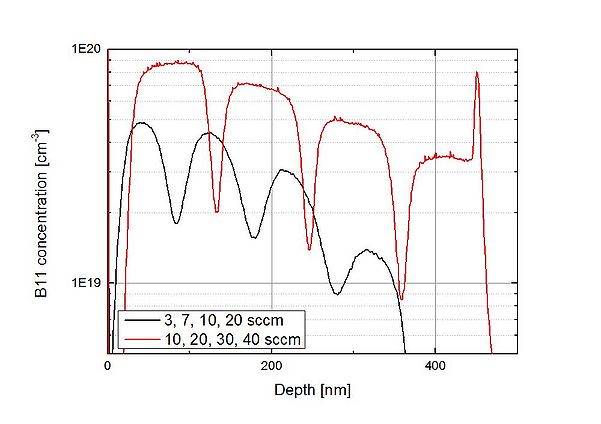

The Boron concentration of the film was controlled by the flow of B2H6 gas. To establish how boron doping concentration varied with B2H6 flow, films of silicon were deposited with B2H6 gas flows modulated during deposition to produce doping spikes. The two figures below show a typical SIMS concentration depth profile of a B2H6 modulation-doped film deposited on a Silicon dioxide substrate. During deposition, the gas flow of SiH4 was held constant, while flows of B2H6 was varied to create the dopant spikes.

Boron-doped amorphous silicon by using 4" LPCVD polysilicon furnace (B4)

Result from Trine Holm Christensen, @Space, Feb. 2015

Process parameters

The test was made on a n-type silicon wafer (100) with a 110 nm grown thermal oxide)

Pressure: 250 mtorr

Temperature: 580 °C

Silane (SiH4) flow: 80 sccm

Diborane (B2H6) flow: 7 sccm

Time: 75 min

Anneal: @950°C for 60 min in N2

Test wafer position: Center of the boat

A better uniformity of the resistivity across the wafer was achieved by subsequently annealing in N2, the annealing was done in Anneal Oxide Furnace (C1). The measured film thickness was 370 nm and the sheet resistance was measured to 200 Ω/sq +/- 15 Ω/sq.