Specific Process Knowledge/Thermal Process/Resist Pyrolysis Furnace

Feedback to this page: click here

This page is written by DTU Nanolab internal

===EXPIRED! The Resist Pyrolysis furnace has been removed from the cleanroom August 2019. Use the Multipurpose Anneal furnace instead.===

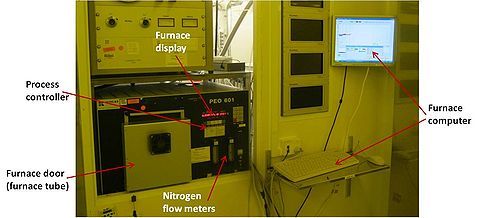

Resist Pyrolysis Furnace

The Resist Pyrolysis Furnace is used for resist pyrolysis, where samples with different resist layers are heated up to maximum 1000 oC in a nitrogen atmosphere. At high temperatures carbon is formed by pyrolysis of the resist. In this way conductive structures can be made from a resist patterned sample.

If oxygen from the air or from outgassing of the resist is present in the furnace, the resist layer will be removed. Thus, for each process it is important to include a step with a high nitrogen flow at a lower temperature, before a high temperature for resist pyrolysis is obtained. Pyrolysis of a large amount of resist may also be a problem due to resist outgassing.

During processing the furnace is rapidly heated by use of six long heating lamps situated around the furnace tube. The furnace is not heated in the ends, and this affects the temperature uniformity in the furnace. Cooling is done (rather slowly) by use of cooling fans.

The furnace is purged with a controlable nitrogen flow.

There is no vacuum on the furnace.

The user manual, user APV and contact information can be found in LabManager:

Process information

There are no standard processes on the furnace.

| Equipment | Reist Pyrolysis Furnace | |

|---|---|---|

| Purpose |

| |

| Process parameter range | Temperature |

|

| Process gasses |

| |

| Vacuum |

| |

| Nitrogen flows |

| |

| Substrates | Batch size |

|

| Allowed materials |

| |