Specific Process Knowledge/Lithography/Coaters

SSE Spinner

SSE Spinner, Maximus 804, SSE Sister Semiconductor Equipment is a resist spinning system at Danchip which can be used for spinning on 2", 4" and 6" substrates. The system is equipped with 2 different resists lines: AZ5214E and AZ4562 and 2 syringe lines, which can be used for spinning of e-beam resist.

The user manual(s), quality control procedure(s) and results and contact information can be found in LabManager: Equipment info in LabManager

Process information

Link to process pages

- Positive process with AZ5214E resist

- Reverse process with AZ5214E resist

- Positive process with AZ4562 resist

- E-beam process with ZEP 520A resist

Information about resist can be found here:

KS Spinner

At Danchip we have RC8-THP system which is one of the SUSS MicroTech spinners.

The main purpose of this equipment is experimental spinning the different resist.The spinner has one resist line, AZ5214E, for automatic dispense. All other resist dispenses manually from syringe or disposable pipettes. All SU8 spinning are done on this machine.

The machine can be also used for spinning on the "difficult" surfaces like the substrates with holes, backside structures and unusual shapes.

The user manual(s), quality control procedure(s) and results and contact information can be found in LabManager: Equipment info in LabManager

Process information

Link to process pages

- Positive process with AZ5214E resist

- Reverse process with AZ5214E resist

- Positive process with AZ4562 resist

- Process with SU8 resist

Information about resist can be found here:

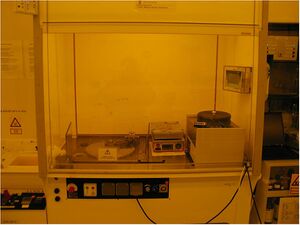

Manual Spinner( Polymers)

The Manual Spinner(Polymers), Opticoat SB20+, from SSE Sister Semiconductor Equipment, are dedicated for spinning of imprint polymers, e-beam resist in small batches, SU8 resist and other polymers with extra addictive like color, nano particles etc.

There are 2 hotplates with temperature range up to 250C, placed in the same fumehood, which can be used for baking before/after spinning.

The user manual(s), quality control procedure(s) and results and contact information can be found in LabManager:

Equipment info in LabManager

Process information

Link to process pages

SÜSS Spinner-Stepper

This spinner is dedicated for spinning DUV resists. The spinner is fully automatic and can run up to 25 substrates in a batch 4", 6", and 8" size. The machine is equipped with the 3 resist lines, a automatic syringe system and a solvent line for cleaning and back-side rinse.

The user manual(s), quality control procedure(s) and results and contact information can be found in LabManager:

Equipment info in LabManager

Information about resist can be found here:

- Bottom Anti Reflection Coating (BARC)DUV 42S-6 .

- Datasheet DUV42S-6.

- Positive DUV resist for spinning in 300-600 thickness range KRF M230Y.

Process information

Link to process pages

| Equipment | SSE Spinner | KS Spinner | |

|---|---|---|---|

| Purpose |

|

| |

| Performance | Substrate handling |

|

|

| Permanent media |

|

| |

| Manual dispense option |

|

| |

| Process parameter range | Parameter 1 |

|

|

| Parameter 2 |

|

| |

| Substrates | Batch size |

|

|

| Allowed materials |

|

| |