Specific Process Knowledge/Etch/DRIE-Pegasus/Etch black silicon

Feedback to this page:click here

- This work was done by Henri Jansen and Bingdong Chang in 2017;

- This page was edited by Bingdong Chang 23 October, 2017.

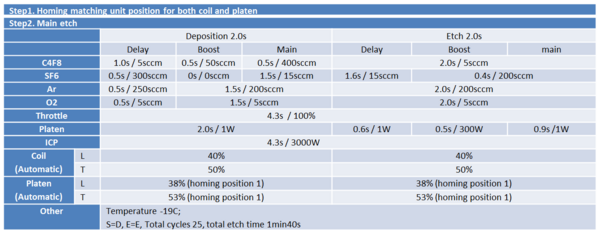

Black silicon has a modified surface, which has several interesting properties, e.g. high absorption of light in visible and infrared wavelengths, hydrophobicity, etc. On DRIE-Pegasus, black silicon can be fabricated with a Bosch process recipe, which takes relatively short process time and a high reproducibility. In the same time, because of the narrow parameter window of black silicon, this process can be used to test the condition of etch tool, which is known as the black silicon method. An example of the black silicon recipe is shown as below:

- Recipe to fabricate black silicon with Bosch process

The SEM images of the surface and cross section of black silicon are shown as below

- SEM images of black silicon sample

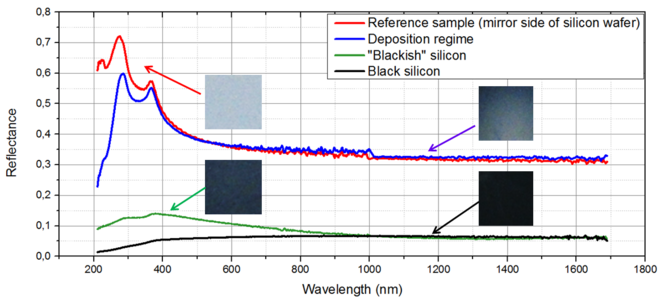

The reflectance of different samples were measured with Ellipsometer VASE. Noticed that the blue curve is the result when more deposition was performed during Bosch process, while the green curve is the result when more etch was performed during Bosch process. When a balance between deposition and etch was achieved, black silicon can be fabricated with a minimum reflectance.

- Reflectance measured with Ellipsometer

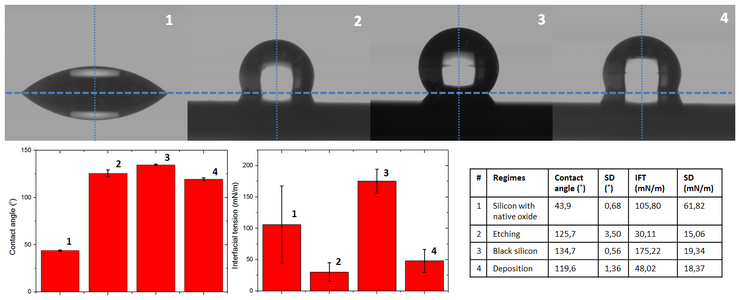

The hydrophobicity of black silicon can be measured with Drop Shape Analyzer. Below is a comparison of contact angles between different samples (a silicon reference sample with native oxide, black silicon, etched silicon with overdesposition or overetch)

- Hydrophobic properties of black silicon surface

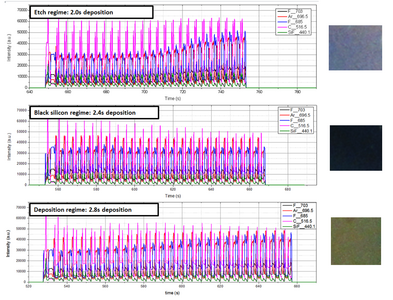

The etch process of black silicon can give a special "fingerprint" on the optical emission spectrometer (or optical endpoint detector system), which means that we can have an in situ monitoring of etch process and identify if the etch result is in overdeposition regime, overetch regime, or in black silicon regime, without direct characterization of the samples. This special feature on OES is shown as below:

- OES in situ monitoring of black silicon etch process

For more details, please contact Henri Jansen (henrija@dtu.dk) or Bingdong Chang (bincha@dtu.dk)