Specific Process Knowledge/Lithography/Coaters

Coaters: Comparison Table

| Equipment | Spin Coater: Gamma UV | Spin Track 1 + 2 | SSE Spinner | Spin Coater: RCD8 | Spin Coater: Manual All Resists | Spin Coater: Manual Standard Resists | Spin Coater: Manual All Purpose | Spray Coater | |

|---|---|---|---|---|---|---|---|---|---|

| Purpose |

|

|

|

|

|

|

|

| |

| Performance | Substrate handling |

|

|

|

|

|

Single substrate |

| |

| Permanent media |

|

|

|

|

Only manual dispense |

| |||

| Manual dispense option |

|

|

|

|

| ||||

| Process parameter range | Spindle speed |

|

|

|

|

|

|

|

|

| Gyrset |

|

|

|

|

|

|

|

||

| Substrates | Substrate size |

|

|

|

|

|

|

|

|

| Batch size |

|

|

|

|

|

|

|

| |

| Allowed materials |

|

|

|

|

|

|

|

| |

SSE Spinner

Feedback to this section: click here

SSE Spinner, Maximus 804, SSE Sister Semiconductor Equipment is a resist spinning system at Danchip which can be used for spinning on 2", 4" and 6" substrates.

The system is equipped with 2 different resists lines:

- AZ 5214E

- AZ 4562

and

- 2 syringe lines, which can be used for spinning of e-beam resist.

The user manual, user APV, and contact information can be found in LabManager

Process information

The typical flow for resist spinning is divided in 3 steps: video, spinning and soft bake. You need to create a separate recipe for each station and then collect the recipes in a flow. For the video station we have 3 standard recipes for 3 different wafer sizes: 2inch, 4inch, 6inch. To create a recipe for the coater station you need to describe spinning sequence using the predefined functions. Then you create recipe for the hotplates. After all recipes are created they can be set together in the different flows. It is why we are not recommending the user just change some parameters in the recipe, this change can effect some other flows.

Flow names, process parameters, and test results:

- _DCH_100mm_AZ5214E_1,5um

Spin-off: 10 s at 2300 rpm closed followed by 10s at 3500 rpm open.

Soft bake: 90 s at 90°C in contact

| Substrate | Thickness | Uniformity (+/-) | Test date | Tester initials | Comments |

|---|---|---|---|---|---|

| Silicon with native oxide | 1,399 | 3,1% | 28/1 2016 | chasil | with HMDS. Average of 3 wafers |

| Silicon with native oxide | 1,418 | 2,5% | 21/2 2016 | chasil | with HMDS. Average of 3 wafers |

- _DCH_100mm_AZ5214E_2,2um

Spin-off: 40 s at 2200 rpm open.

Soft bake: 60 s at 90°C in contact

- _DCH_100mm_AZ5214E_1,5um

Spin-off: 60 s at 725 rpm open with exhaust closed followed by 10s at 3500 rpm open.

Soft bake: 90 s at 95°C in 1 mm proximity

| Purpose |

| ||

|---|---|---|---|

| Resist |

| ||

| Performance | Coating thickness |

| |

| Process parameters | Spin speed |

100 - 5000 rpm | |

| Spin acceleration |

100 - 10000 rpm/s | ||

| Hotplate temperature |

| ||

| Substrates | Substrate size |

| |

| Allowed materials |

All cleanroom materials except III-V materials | ||

| Batch |

1 - 24 | ||

Spin Track 1 + 2

Feedback to this section: click here

Spin Track 1 + 2 is an SVG 88 series track system from Rite Track. Each track consists of a HMDS priming module, a spin coating module, and a baking module. In fact, the only difference between the two tracks is the resist used in the spin coating module. Spin Track 1 + 2 is capable of handling 150 mm wafers, as well as 100 mm wafers, but is currently set up for 100 mm wafer processing.

The Spin Track 1 + 2 is controlled using the Recipe Manager software via the touchscreen on the arm attached to the lefthand end of the track. Recipes for the individual modules are developed by Danchip and combined into flows. The user selects a flow (specific to track 1 or 2), and the appropriate recipes will be downloaded and executed on the appropriate track. The other track runs an empty process (no wafers needed), and can unfortunately not be used by a second user while the first user is processing.

The user manual, user APV, and contact information can be found in LabManager

Process information

- General Spin Track 1 + 2 process information

- HMDS priming on Spin Track 1 and 2

- AZ MiR 701 (29cps) coating on Spin Track 1

- AZ nLOF 2020 coating on Spin Track 2

- Post-exposure baking on Spin Track 2

| Spin Track | 1 | 2 | |

|---|---|---|---|

| Purpose |

|

| |

| Resist |

AZ MiR 701 (29cps) positive tone |

AZ nLOF 2020 negative tone | |

| Performance | Coating thickness |

1 - 3 µm |

1 - 4 µm |

| HMDS contact angle |

60° - 90°; standard recipe 82° (on SiO2) | ||

| Process parameters | Spin speed |

10 - 9990 rpm | |

| Spin acceleration |

1000 - 50000 rpm/s | ||

| Hotplate temperature |

90°C |

110°C | |

| HMDS priming temperature |

50°C | ||

| Substrates | Substrate size |

100 mm wafers | |

| Allowed materials |

Silicon and glass wafers Film or pattern of all types | ||

| Batch |

1 - 25 | ||

Spin Coater: Gamma UV

Feedback to this section: click here

Spin Coater: Gamma UV was installed at Danchip in March 2015. It is a Gamma 2M cluster from Süss MicroTec with spin coating, vapour priming, and baking modules. The system handles 4" and 6" wafers without size conversion, and can be set up to handle 2" or 8".

The coater is equipped with 3 different resists lines:

- AZ MiR 701

- AZ nLOF 2020

- AZ 5214E

and

- 1 syringe, which can be used for various resists.

The processes that are available on the system are developed by Danchip. Upon request, it is possible to establish new processes. Use of the syringe requires special training, and would as a starting point require batches in excess of 20 wafers.

The user manual, user APV, and contact information can be found in LabManager

Process information

| Purpose |

| |

|---|---|---|

| Resist |

| |

| Performance | HMDS contact angle |

60 - 80° |

| Coating thickness |

| |

| Process parameters | Priming temperature |

25 - 120 °C |

| Spin speed |

10 - 6000 rpm | |

| Spin acceleration |

10 - 10000 rpm/s | |

| Hotplate temperature |

25 - 200 °C | |

| Cool plate temperature |

21 °C | |

| Substrates | Substrate size |

|

| Allowed materials |

Silicon and glass | |

| Batch |

1 - 25 |

1) Requires tool change.

Spin Coater: RCD8

Feedback to this section: click here

Spin Coater: RCD8 is a model RCD8 T spin coater from Süss MicroTec with a motorized media arm and Gyrset functionality. It's primary purpose is spin coating of SU-8 resist. However, due to the possibility of using a non-vacuum chuck, the spin coater can also be used for coating of substrates with e.g. textured backsides or membranes.

The user manual, user APV, and contact information can be found in LabManager

Process information

| Purpose |

| |

|---|---|---|

| Resist |

| |

| Performance | Coating thickness |

|

| Process parameters | Spin speed |

Vacuum chuck: 10 - 5000 rpm |

| Spin acceleration |

10 - 3000 rpm/s | |

| Substrates | Substrate size |

|

| Allowed materials |

All cleanroom materials ? | |

| Batch |

1 |

Manual Spin Coaters

Go back to Coater comparison table.

|

|

|

| Spin Coater: Manual All Resists | Spin Coater: Manual Standard Resists | Spin Coater: Manual All Purpose |

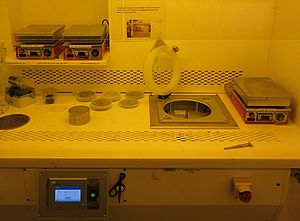

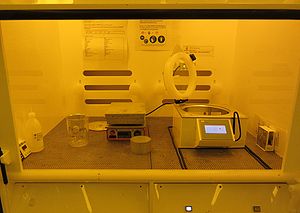

| Loacted in fumehood in A-5 | Located in fumehood in E-5 | Located in fumehood in C-1 |

| Labspin 6, Süss | Labspin 6, Süss | WS-650, Laurell |

| LabManager | LabManager | LabManager |

Training video: LabSpin6

Spin curves: AZ 5214E, AZ nLOF 2020, ZEP 520A, FOX-15